Lens assembled system

A technology for assembling systems and lens modules, applied in installation, optics, instruments, etc., can solve the problems of wasting manpower, reducing the assembly efficiency of lens modules, wasting man-hours, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

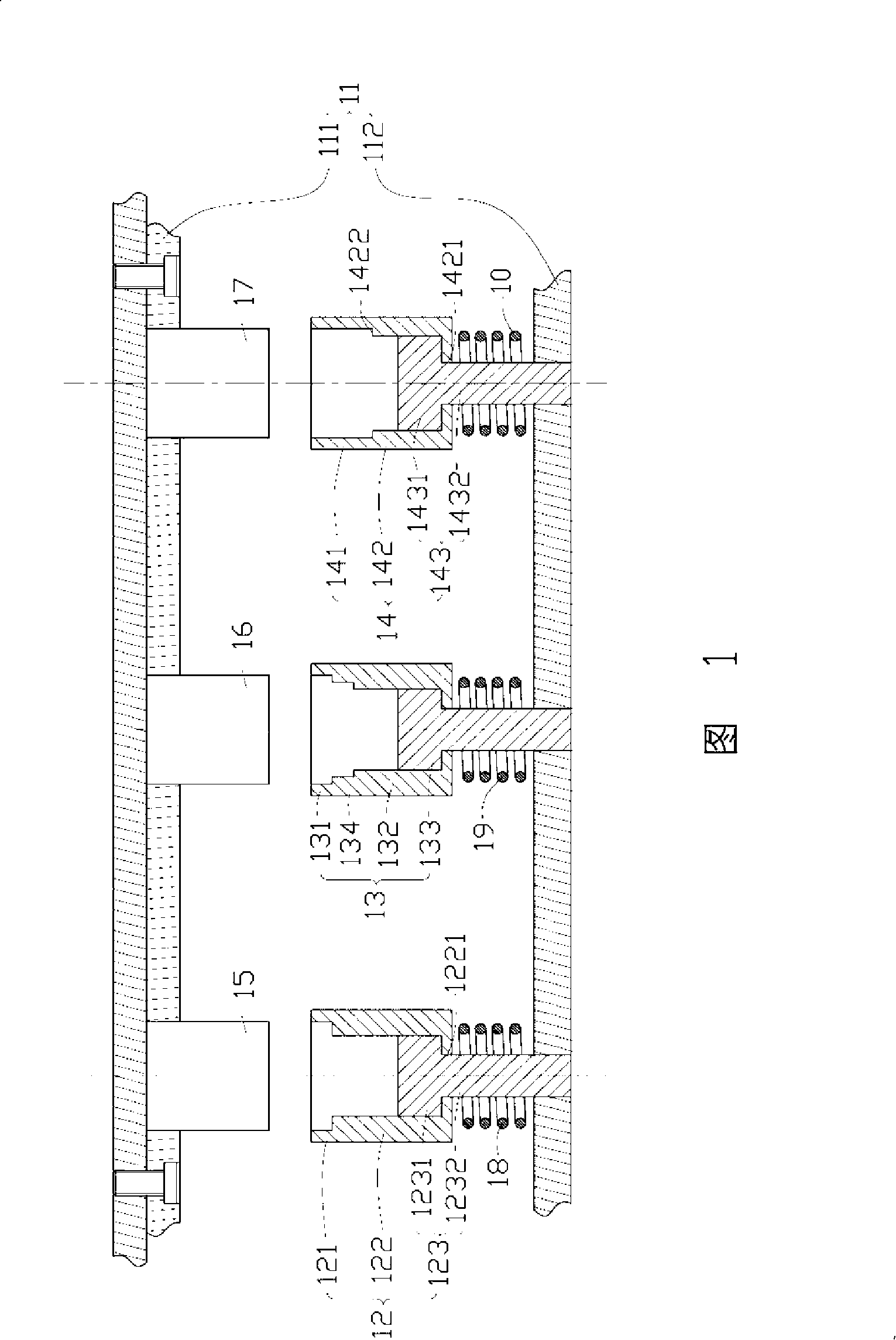

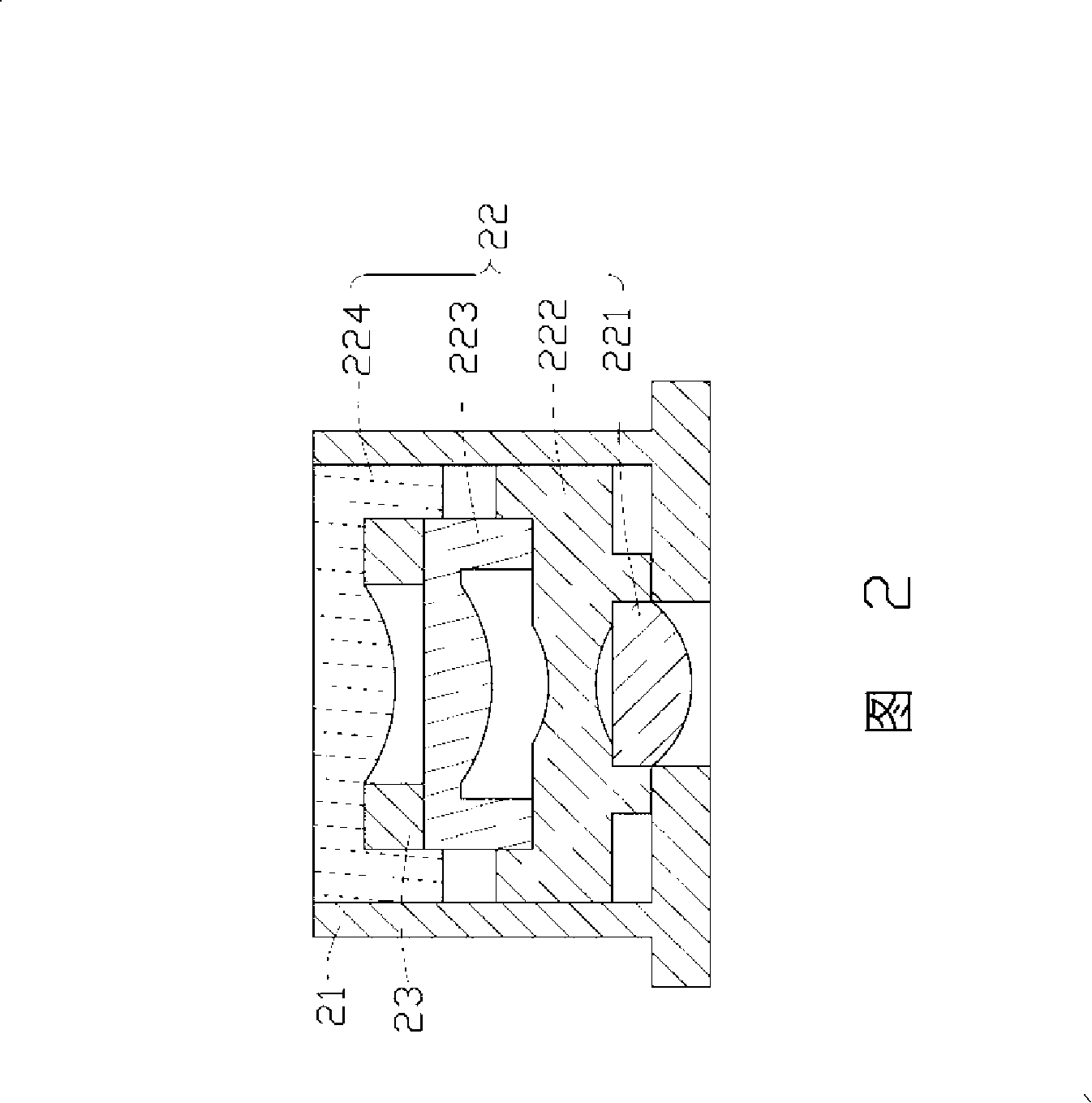

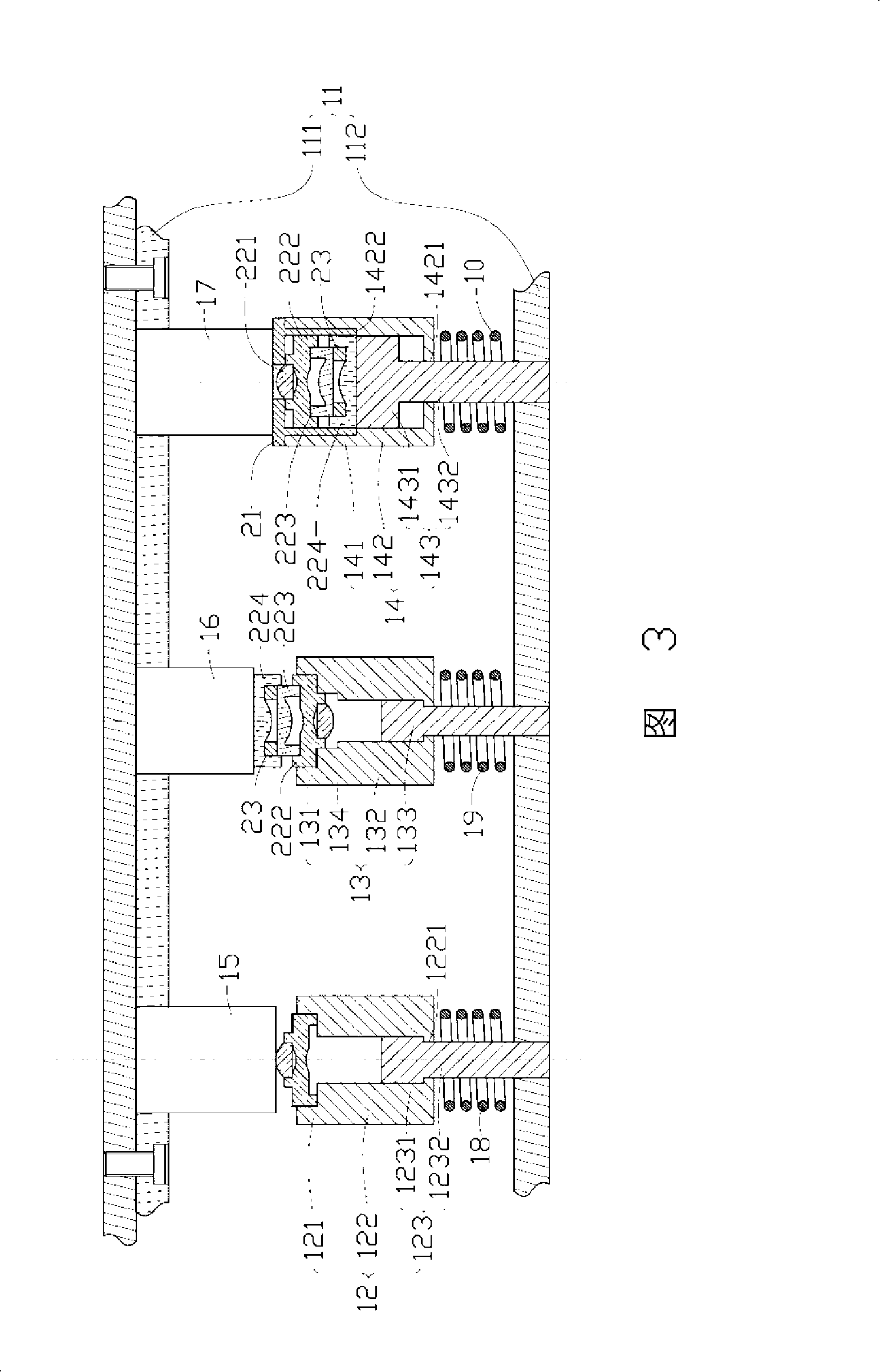

[0011] In order to further illustrate the present invention, a preferred embodiment is given and described in detail below with accompanying drawings.

[0012] Please refer to Fig. 1 and Fig. 2, the lens assembly system of the embodiment of the present invention is used for assembling the lens module 20, and the lens assembly system includes a base 11, a first optical element assembly jig arranged on the base 11 12 and the second optical element assembly jig 13, a lens assembly jig 14 arranged on the base 11 and corresponding to the first and second optical element assembly jigs 12, 13 and the lens assembly jig 14 And the first, second and third push rods 15 , 16 and 17 are arranged on the base 11 . Preferably, an elastic member 18, 19, 10 is respectively provided between the first and second optical element assembly jigs 12, 13 and the lens assembly jig 14 and the base 11 for buffering Corresponding first, second, the impulse of the third push rod 15,16,17.

[0013] The len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com