Upright tropism type crystal tropism agent and upright tropism type crystal display element

A liquid crystal aligning agent and vertical alignment technology, applied in liquid crystal materials, optics, instruments, etc., can solve problems such as difficulty in prediction, deterioration of electrical characteristics, and reduction of printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0113] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited to these examples.

[0114] In addition, various measurements of Examples and Comparative Examples were performed as follows.

[0115] (1) Determination of voltage retention rate

[0116] A voltage of 5 V was applied to the liquid crystal display element at 60° C. for an application time of 60 microseconds and a time interval of 16.7 microseconds, and then the voltage retention rate 16.7 milliseconds after the application was released was measured.

[0117] (2) Afterimage evaluation by brightness

[0118] Two sets of liquid crystal display elements were prepared, one of which was subjected to a DC voltage of 1 V for 2 hours at room temperature (element A), and the other was applied with a DC voltage of 5 V for 2 hours at room temperature (element B). Then, when the luminance of the element A and element B observed when a 2.5V DC voltage w...

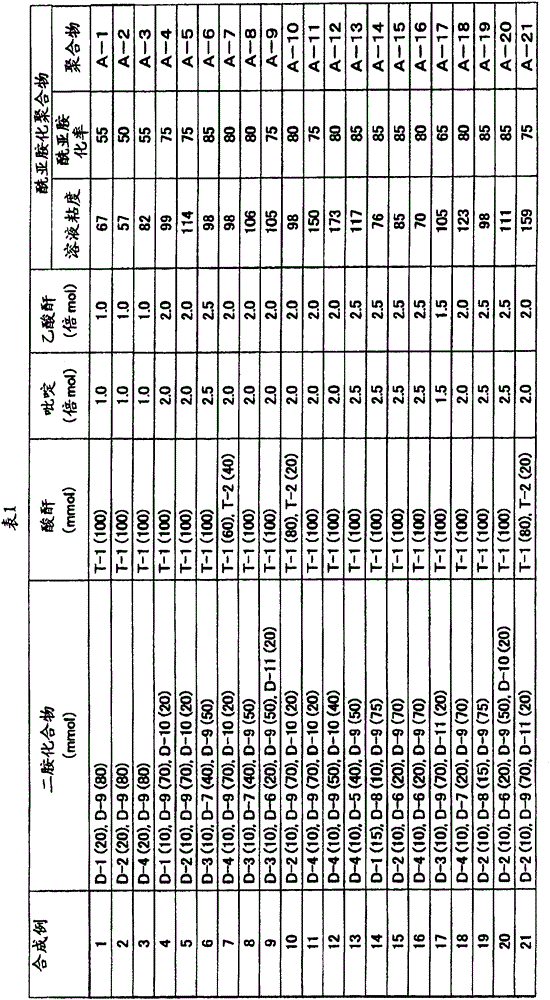

Synthetic example 1~21

[0132] In N-methyl-2-pyrrolidone, diamine and tetracarboxylic dianhydride (in the table, expressed as "acid anhydride") were sequentially added with the composition shown in Table 1 to make a solution with a solid content concentration of 20% by weight. The reaction was carried out at 60° C. for 4 hours to obtain a polyamic acid polymer. To the obtained polyamic acid polymer, pyridine and acetic anhydride were added in multiple molar numbers as shown in Table 1 with respect to the total amount of the polyamic acid polymer, and then heated to 110° C. for 4 hours for a dehydration ring-closure reaction. After the obtained solution was reprecipitated with diethyl ether, it was collected and dried under reduced pressure to obtain (A-1) to (A-21 ).

[0133]

[0134] In Table 1, the numbers in parentheses indicate the content ratio (molar ratio) of the diamine compound and the acid anhydride, and the meanings of the symbols in the table are as follows.

[0135]

[0136] D-1: ...

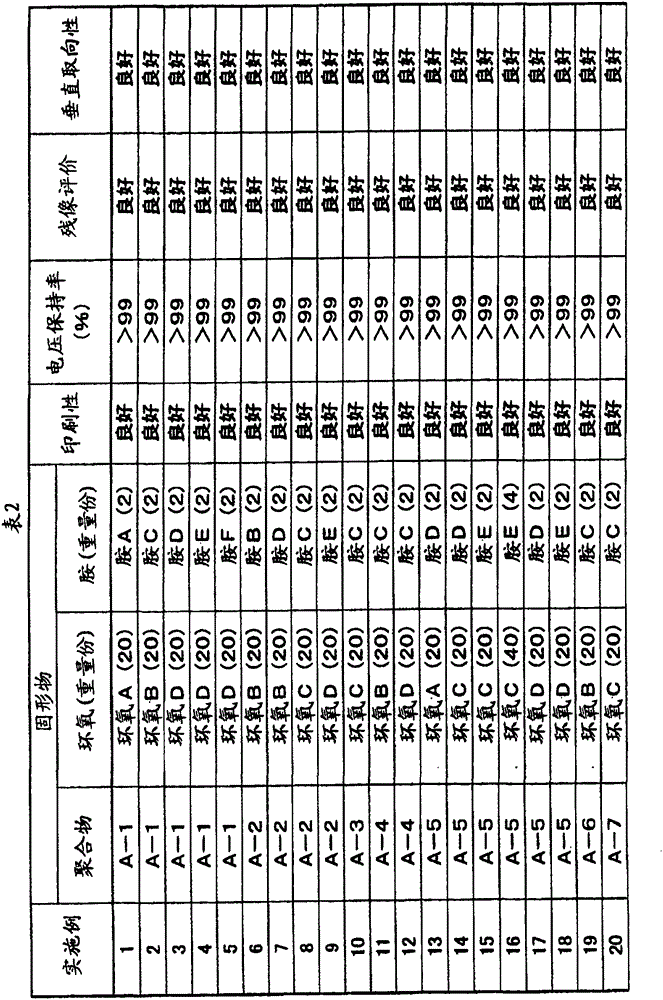

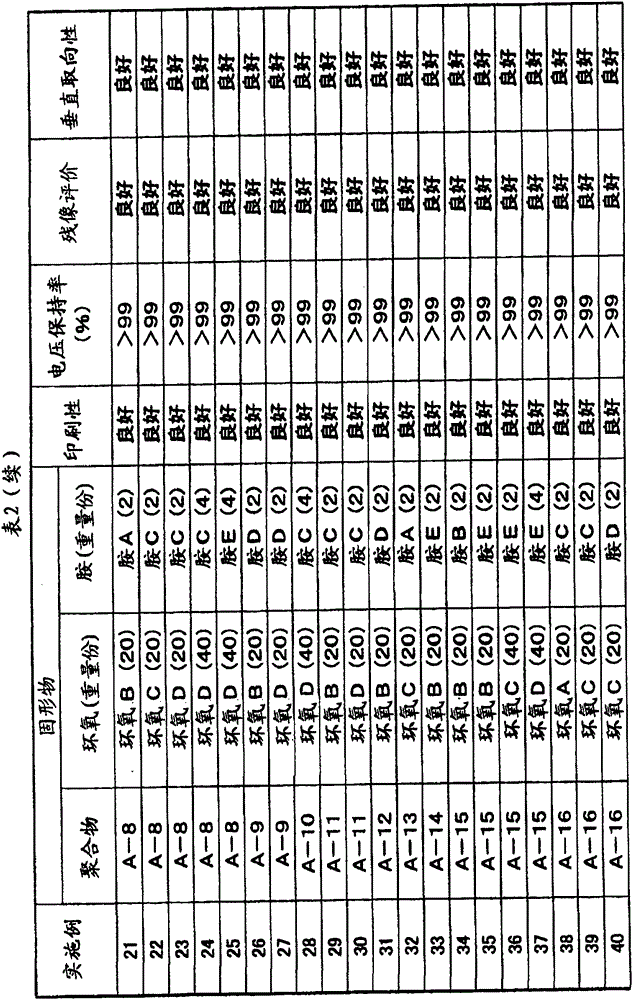

Embodiment 1

[0152] The imidized polymer (A-1) obtained in Synthesis Example 1 was dissolved in γ-butyrolactone / N-methyl-2-pyrrolidone / butyl cellosolve mixed solution (weight ratio 40 / 30 / 30), Dissolve benzene-1,4-diphenol diglycidyl ether (epoxy A) and n-propylamine (amine A) in proportions of 20 parts by weight and 2 parts by weight relative to 100 parts by weight of the polymer to make a solid concentration 6.5% by weight of the solution, the solution was visually observed as a transparent solution without turbidity. Next, the film-forming composition of the present invention was prepared by filtration using a filter with a pore size of 0.2 μm, and then the printability was evaluated. It was confirmed that the coating film had good printability, with no tearing and coating unevenness.

[0153] Next, the film-forming composition of the present invention was prepared in the same manner as above except that the solid content concentration was 4% by weight.

[0154] Next, the film-forming c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com