Method for extracting aluminum oxide and white carbon black from bituminous shale waste slag

A kind of oil mother shale, alumina technology, applied in alumina/hydroxide preparation, silicon oxide, silicon dioxide and other directions, can solve the problem of oil mother shale waste can not be fully utilized, waste and other problems, achieve low cost, improve utilization rate, increase economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1:

[0030] A. Extract alumina:

[0031] ① Take 100g of kerogen shale waste residue after grinding to below 100 mesh and roasting and activating at 550℃ for 2 hours;

[0032] ②Add 30% H in the waste residue according to the solid-liquid ratio of 1:3 2 SO 4 The solution is heated to 92-98°C to react for 5 hours, cooled, filtered with suction to obtain filtrate and filter residue, and the filter residue is to be extracted with white carbon black;

[0033] ⑨Add 20% NaOH solution to the filtrate until the pH of the filtrate is 13, so that the Fe(OH) produced by the reaction 3 , Mg(OH) 2 , Ca(OH) 2 Wait for the slag to settle and filter to obtain sodium aluminate NaAlO 2 filtrate;

[0034] ④From sodium aluminate NaAlO 2 CO is passed into the bottom of the filtrate 2 Gas to Al(OH) produced by reaction 3 All precipitation, suction filtration to obtain Al(OH) 3 precipitation;

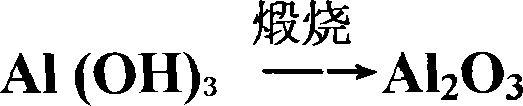

[0035] ⑤The obtained Al(OH) 3 Al is obtained by precipitation drying and calcination 2 O 3 .

[0...

Example Embodiment

[0040] Example 2:

[0041] A. Extract alumina:

[0042] ① Take 300,000 g of kerogen shale residue after grinding to below 100 mesh and roasting and activating at 550°C for 2 hours;

[0043] ②Add 35% H in the waste residue according to the solid-liquid ratio of 1:4 2 SO 4 The solution is heated to 92-98°C to react for 5 hours, cooled, filtered with suction to obtain filtrate and filter residue, and the filter residue is to be extracted with white carbon black;

[0044]③Add 30% NaOH solution to the filtrate until the pH of the filtrate is 13, so that the Fe(OH) produced by the reaction 3 , Mg(OH) 2 , Ca(OH) 2 Wait for the slag to settle and filter to obtain sodium aluminate NaAlO 2 filtrate;

[0045] ④From sodium aluminate NaAlO 2 CO is passed into the bottom of the filtrate 2 Gas, to Al(OH) produced by the reaction 3 All precipitation, suction filtration to obtain Al(OH) 3 precipitation;

[0046] ⑤The obtained Al(OH) 3 Al is obtained by precipitation drying and calcination 2 O 3 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap