Underwater anti-knock support

A technology of anti-seismic bearings and support plates, applied in the direction of construction, bridge construction, bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

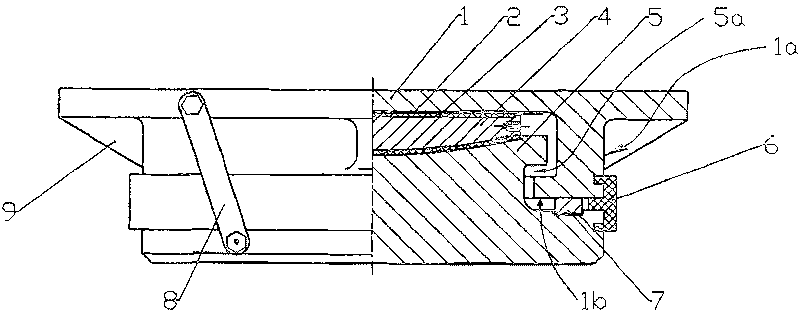

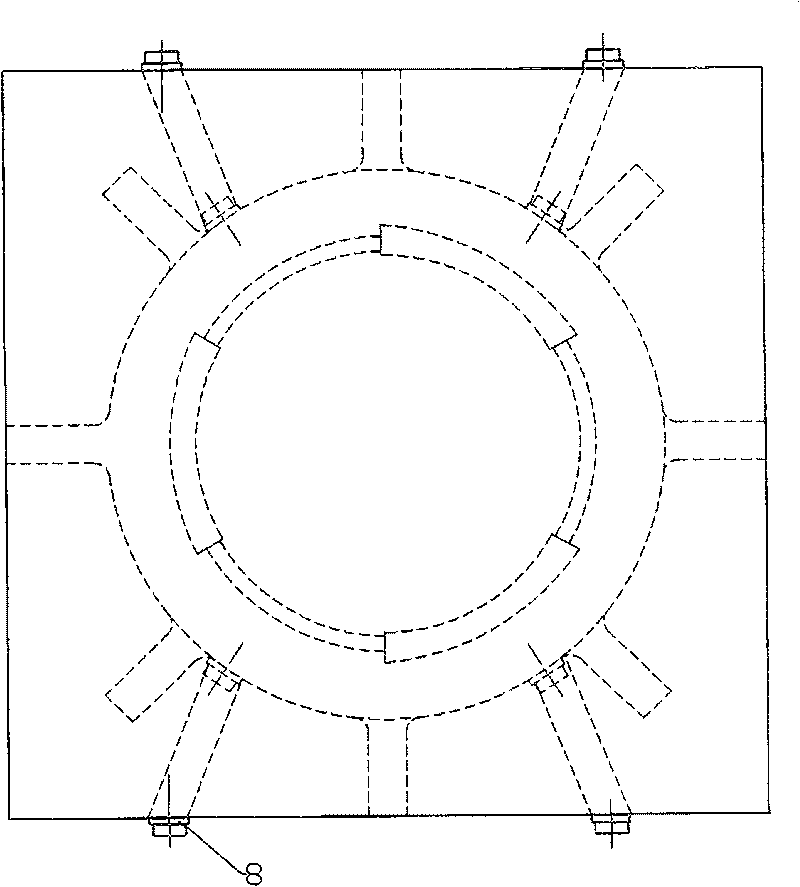

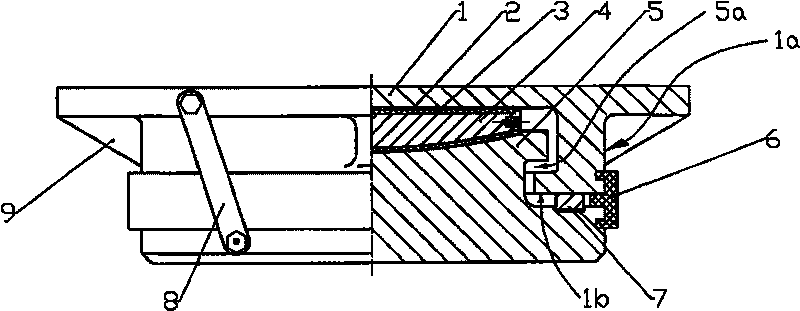

[0013] Such as figure 1 with figure 2 As shown, it is a schematic diagram of an embodiment of the underwater anti-seismic bearing of the present invention. The underwater anti-seismic bearing includes an upper cover 1 and a base 5. The upper surface of the base 5 has a concave surface, and a lower surface is placed in the concave surface, which is a hyperboloid or The center core 4 of the spherical crown surface, the upper cover 1 is placed on the center core 4, the stainless steel plate 2 is welded on the lower surface of the upper cover 1 corresponding to the center core 4, and polytetrafluoroethylene is placed between the stainless steel plate 2 and the center core 5 The plate 3 is also cushioned with a polytetrafluoroethylene spherical plate between the core 4 and the base 5 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| aging coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com