Close range photography measuring device based on flat mirror and photogrammetric survey method

A technology of close-range photography and measurement devices, which is applied in photogrammetry/video measurement, measurement devices, camera devices, etc., to achieve the effects of improving work efficiency, ensuring measurement safety, and reducing the height of photography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

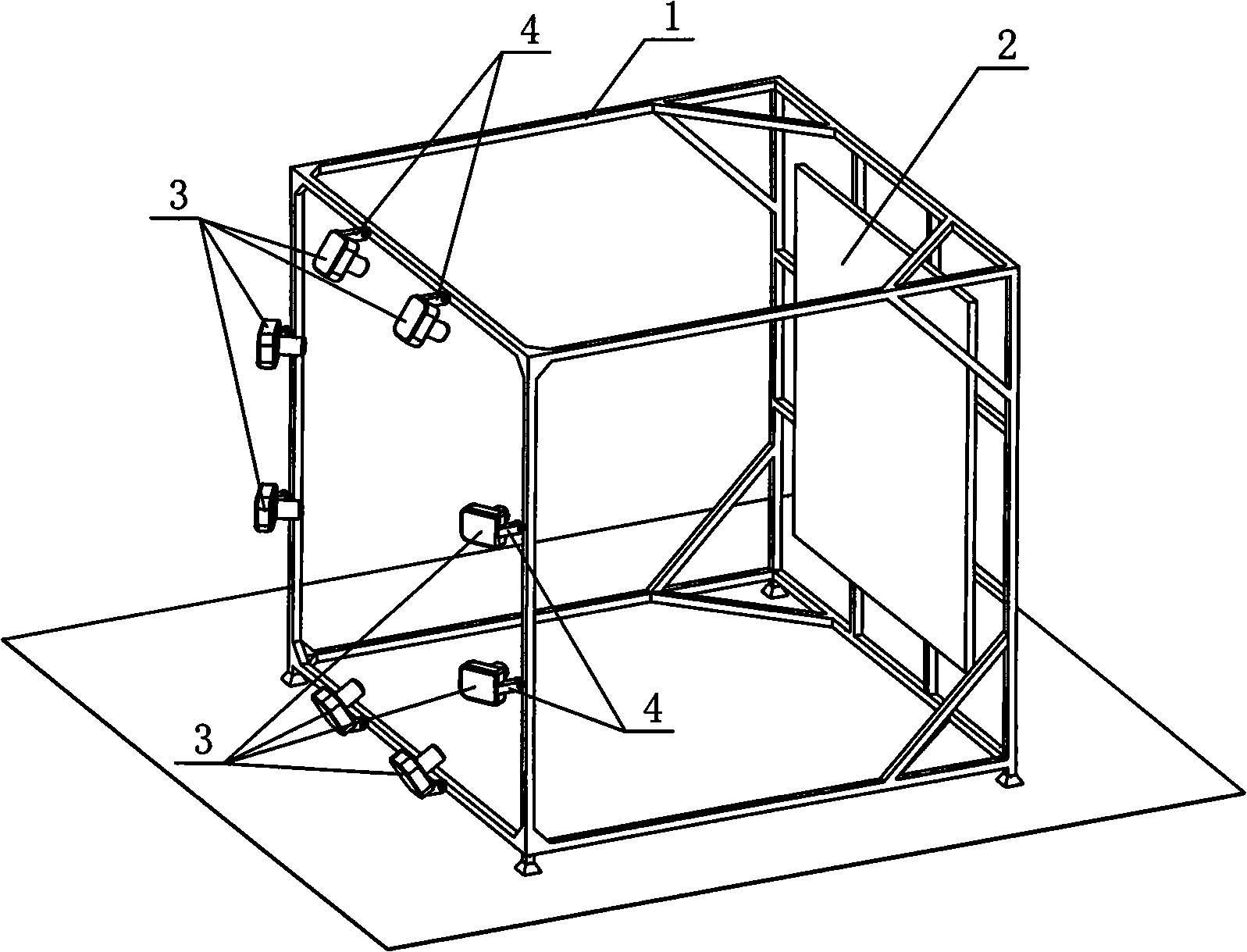

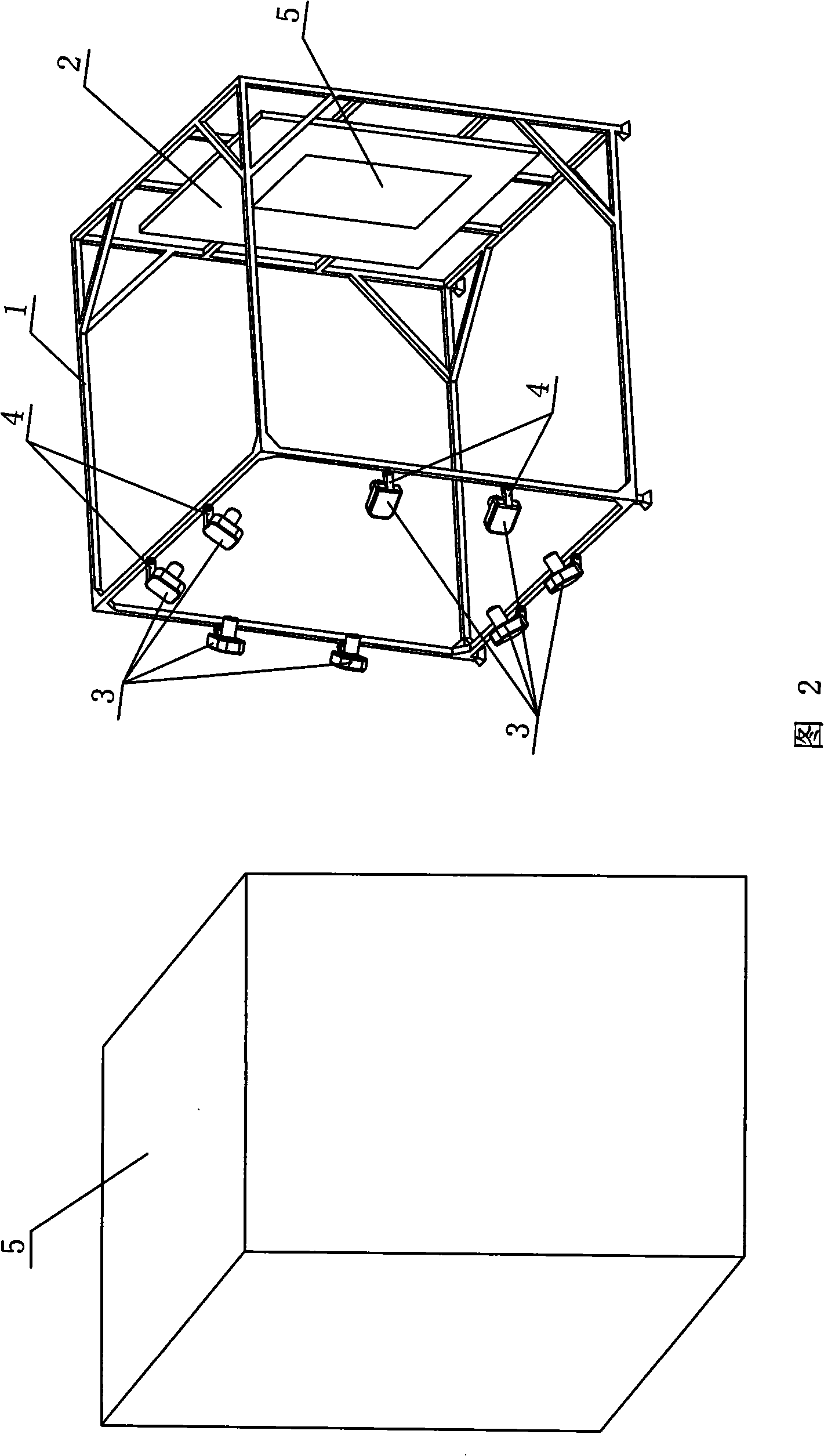

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises three-dimensional frame 1, plane mirror 2 and video camera 3, and plane mirror 2 is arranged on a face inside three-dimensional frame 1 and is perpendicular to the ground, camera 3 is arranged on three-dimensional frame 1 and is opposite to plane mirror 2 positions , the lens of the camera 3 is aimed at the plane mirror 2. The present invention combines the mirror imaging of the plane mirror 2 with close-range photogrammetry by means of a plane mirror 2. The function of the plane mirror 2 is equivalent to "shrinking" the size of the object to be photographed, thereby greatly simplifying the complexity of the measurement work. Therefore, the present invention is particularly It is suitable for shooting objects of huge size, or for photogrammetry of large objects in limited indoor space.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and the first embodiment is that it also adds a rotation adjustment device 4, one end of the rotation adjustment device 4 is connected with the camera 3, and the other end of the rotation adjustment device 4 is hinged on the three-dimensional frame 1 . This design can make the camera 3 adjust the angle on the stereoscopic frame 1 so as to capture a suitable shooting angle.

specific Embodiment approach 3

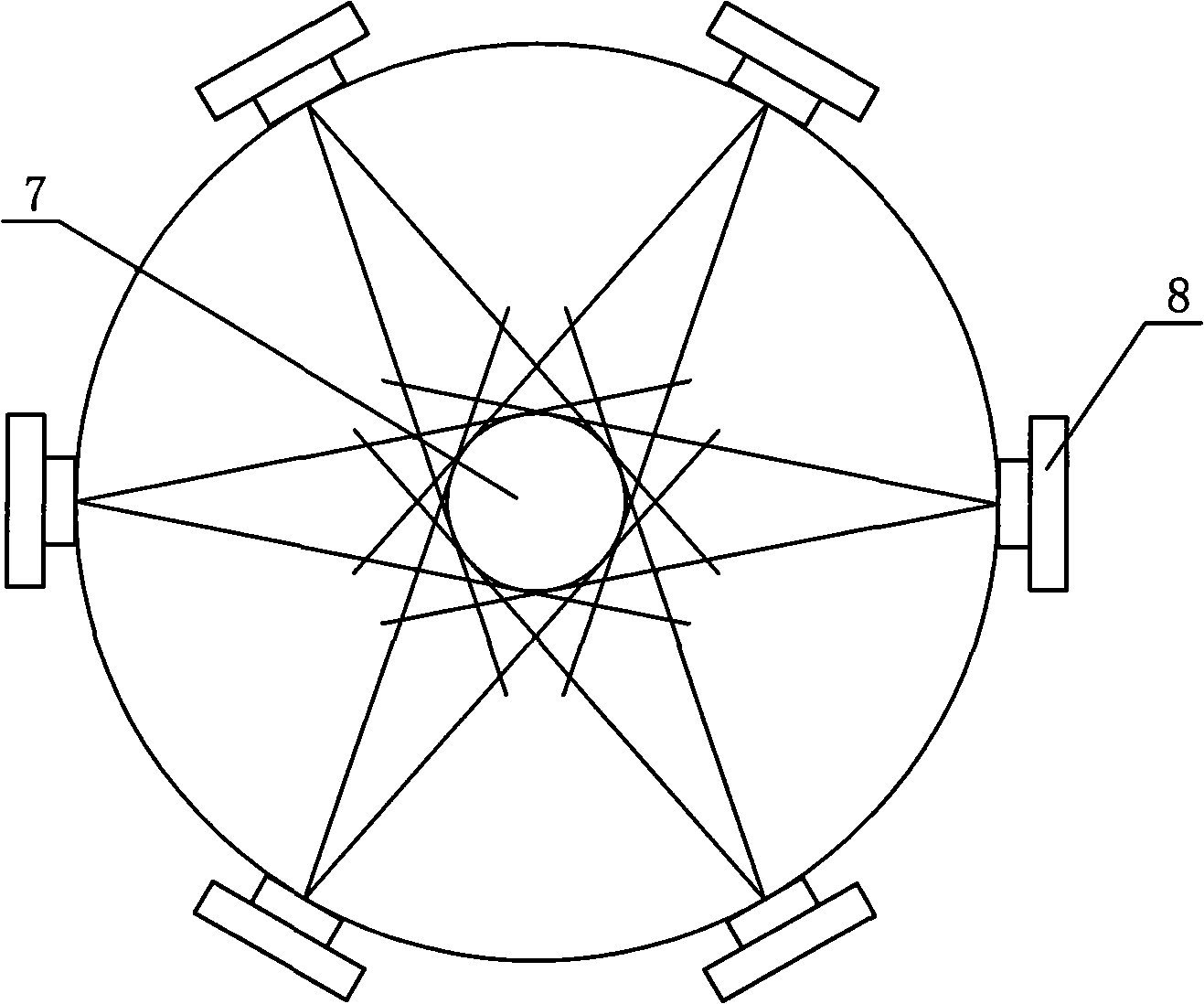

[0010] Specific implementation mode three: combination figure 1 This embodiment will be described. In this embodiment, the number of cameras 3 disposed on the three-dimensional frame 1 and opposite to the plane mirror 2 is 4-8. The number of cameras 3 within this range can increase the number of photographs collected and make the measurement results more accurate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap