Colored composition and photosensitive transfer material

A technology for coloring compositions and transfer materials, which can be applied to photosensitive materials for opto-mechanical equipment, nanotechnology for materials and surface science, optics, etc. To deal with problems such as many processes, to achieve the effect of small environmental impact, high shading performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

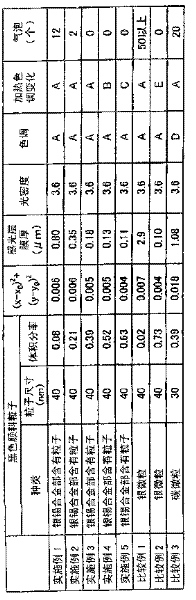

Embodiment 1~5

[0153]

[0154] In 1000ml of pure water, dissolve 23.1g of silver (I) acetate, 65.1g of tin (II) acetate, 54g of gluconic acid, 45g of sodium pyrophosphate, 2g of polyethylene glycol (molecular weight 3,000) and E735 (ISP・Japan Co., Ltd. ) system; vinylpyrrolidone / vinyl acetate copolymer) 5g to obtain solution 1.

[0155] Separately, 36.1 g of hydroxyacetone was dissolved in 500 ml of pure water to obtain a solution 2.

[0156] The obtained solution 1 was vigorously stirred while being kept at 25° C., and at the same time, the solution 2 was added thereto over 2 minutes, and stirring was continued slowly for 6 hours. In this way, the mixed solution turned black, and metal particles having silver-tin alloy parts (particles containing silver-tin alloy parts) were obtained. Next, the solution was centrifuged to precipitate the silver-tin alloy-containing particles. Centrifugation was divided into small portions of 150 ml, and was performed for 30 minutes at a rotation speed o...

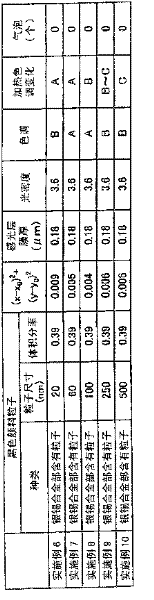

Embodiment 6~10

[0248] The average particle sizes of the silver-tin alloy part-containing particles in the silver-tin alloy part-containing particle dispersion liquid A1 used in Example 3 are 20 nm, 60 nm, 100 nm, 250 nm, and 500 nm, respectively, in the same manner as in Example 3 Then, a light-shielding layer for a display device was formed. The results are shown in Table 2.

[0249] The optical density, film thickness, black tone, heating change of tone, and air bubbles all meet the practical level.

[0250] [Table 2]

[0251] Table 2

[0252]

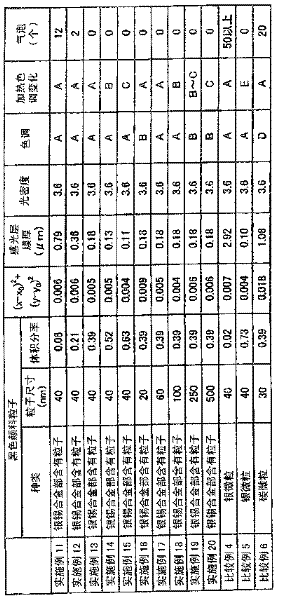

Embodiment 11~20

[0254] In Examples 1-10, except not having provided the protective layer on the photosensitive layer, it carried out similarly to Examples 1-10, respectively, and produced the light-shielding layer for display devices. These samples cannot be used in the 70mJ / cm2 ultra-high pressure mercury lamp 2 The light-shielding layer for display devices can be formed under the exposure of 500mJ / cm 2 A good light-shielding layer for a display device was obtained under a certain exposure. Therefore, when making samples used in film thickness measurement, optical density measurement, and volume fraction measurement, the exposure conditions were changed from 70mJ / cm 2 Changed to 500mJ / cm 2 . The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com