Fuel cell system and method for the operation of a reformer

A fuel cell system and fuel cell technology, used in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as carbon deposition, and achieve the effect of reducing carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

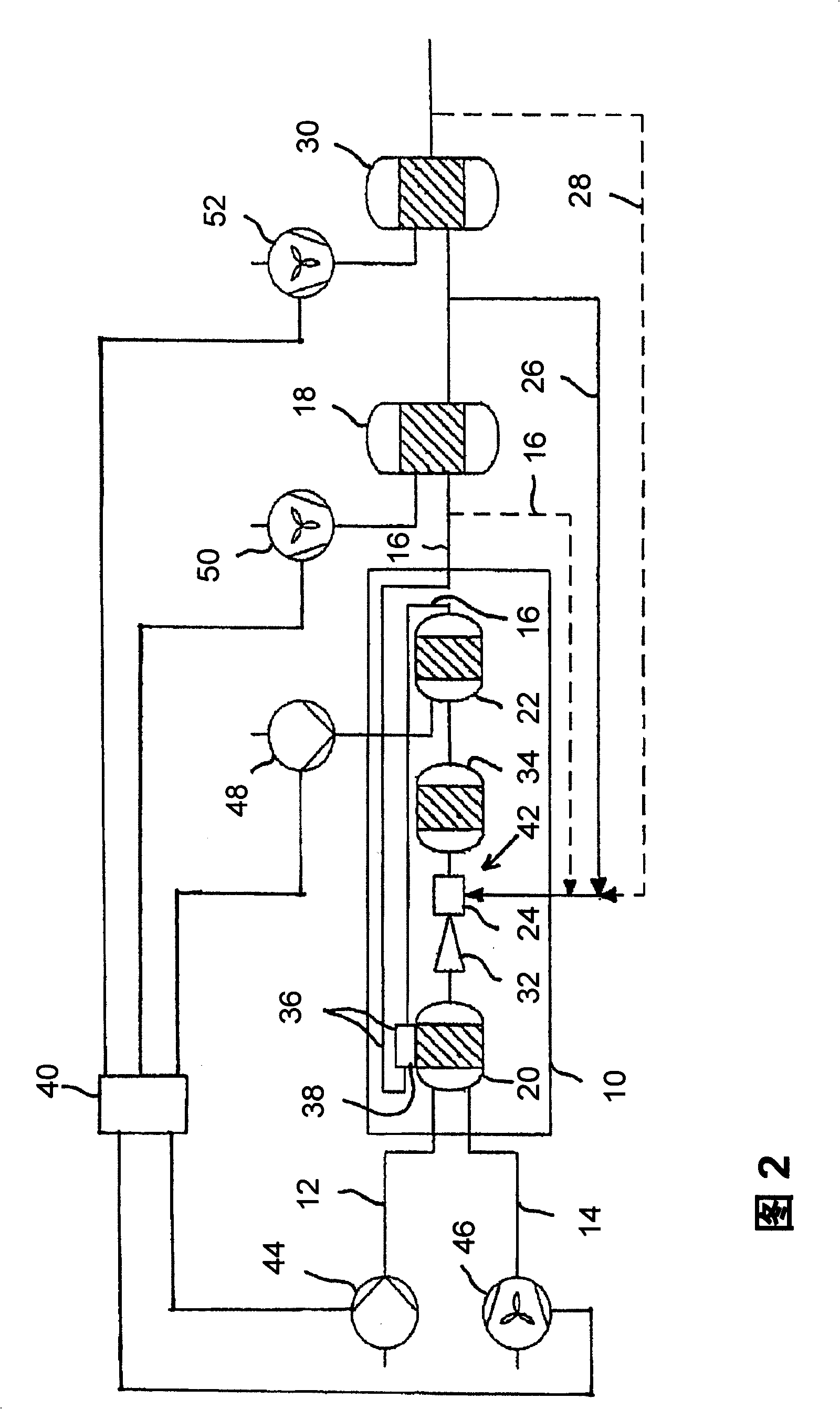

[0027] The embodiment of a fuel cell system according to the present invention shown in FIG. 2 includes a reformer 10 for converting a fuel 12 and an oxidant 14 into a reformate 16 . Fuel 12 , such as petrol or diesel, is fed to the reformer 10 via a fuel pump 44 . In this case, the air 14 fed into the reformer 10 by means of the reforming blower 46 is used as the oxidizing agent. A part of the reformate 16 produced by the reformer 10 is sent to the fuel cell 18 or the fuel cell stack, and the hydrogen-containing gaseous reformate sent to the fuel cell 18 is sent to the fuel cell 18 by means of a fuel blower 50. The incoming cathode air is converted into electric current and heat. In this case, the reformate depleted by conversion in the fuel cell 18 is fed to an afterburner 30 , for example a perforated burner equipped with an afterburner blower 52 .

[0028]The reformer 10 includes a reforming burner 20 into which a fuel 12 and an oxidant 14 are fed. In addition, the refo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com