Friable plate material package structure

A packaging structure and plate technology, applied in transportation and packaging, packaging of vulnerable items, types of packaging items, etc., can solve the problems of occupying space, difficult to automate, and large box volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

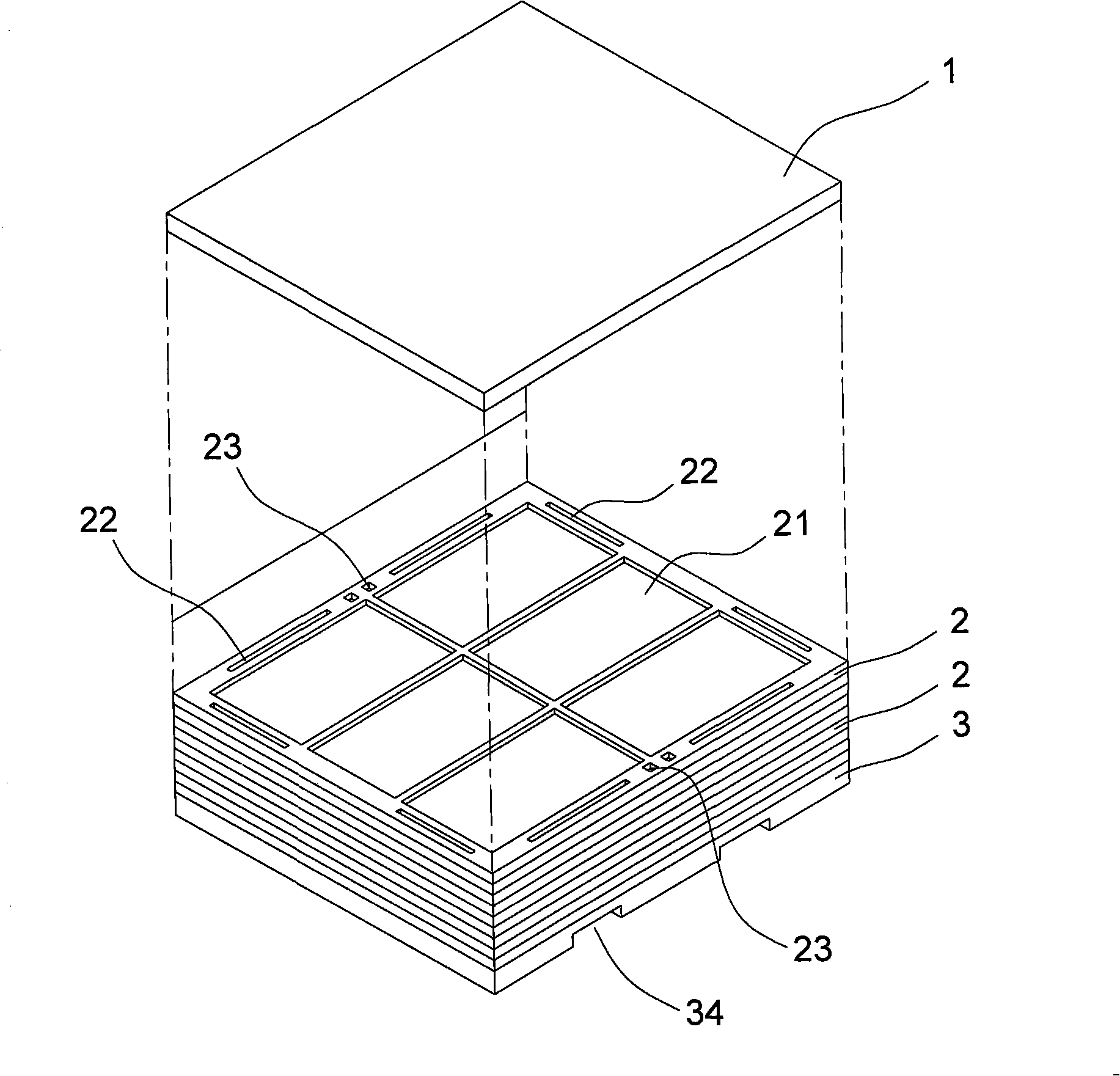

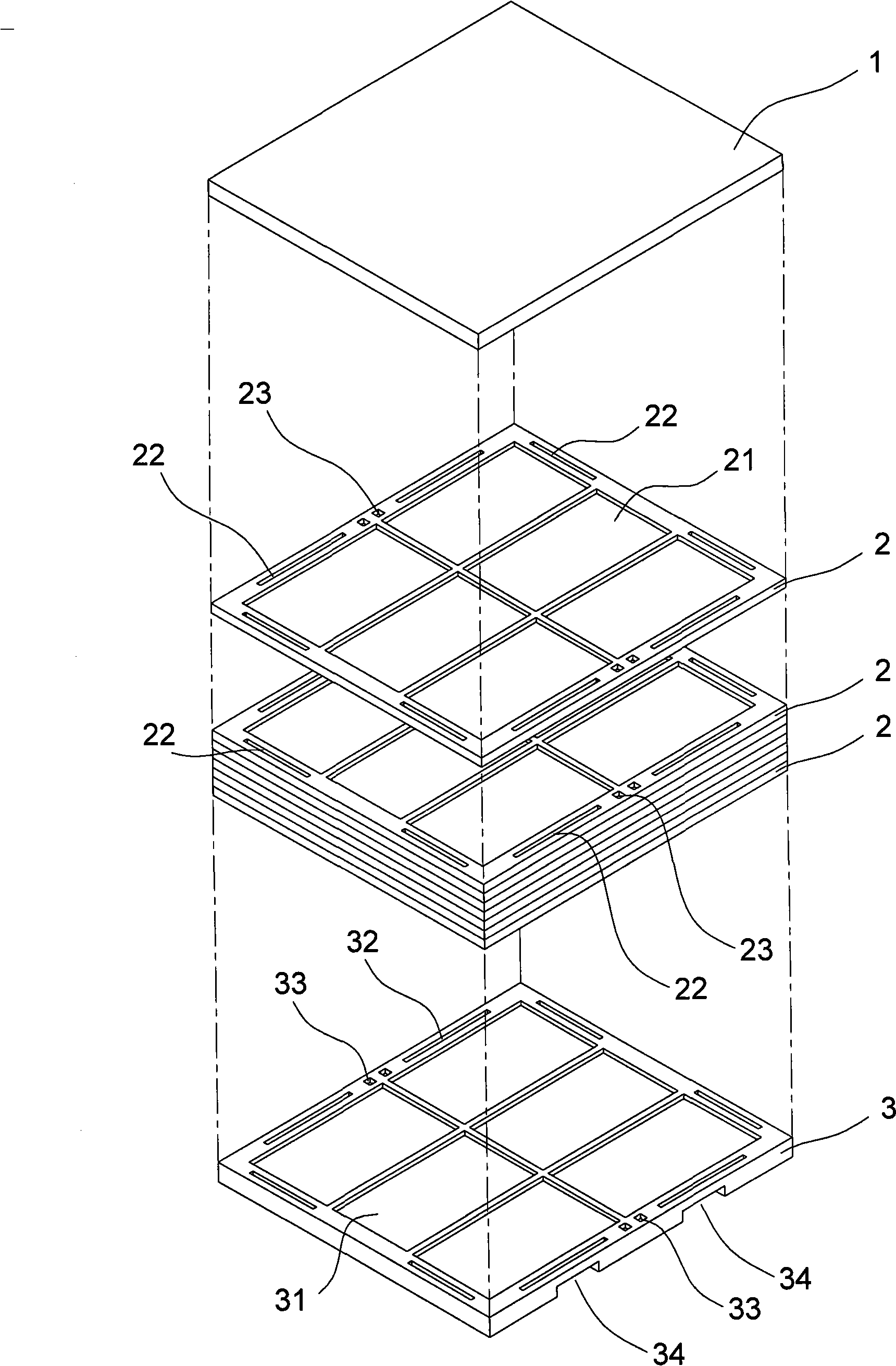

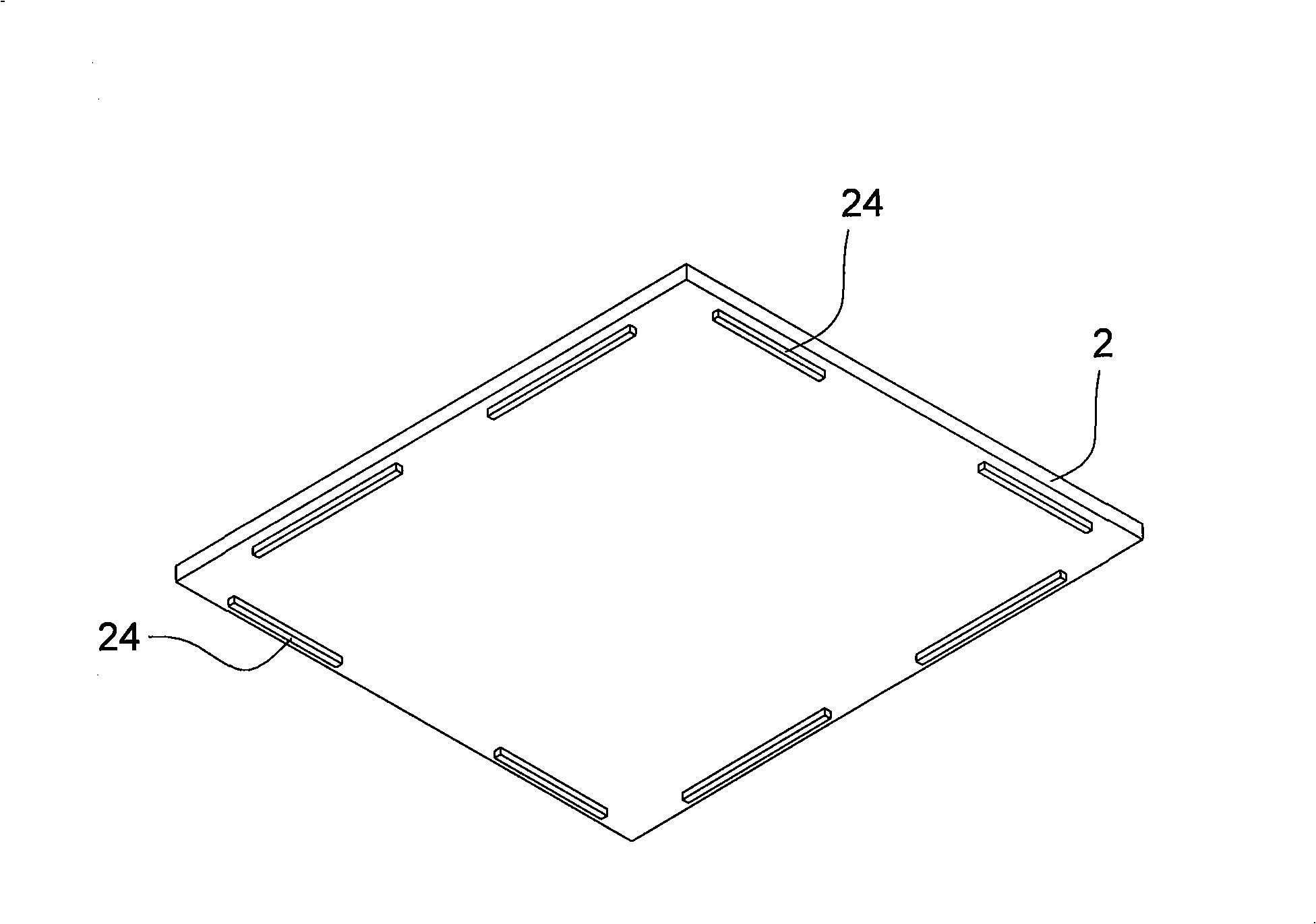

[0030] See first figure 1 , figure 2 and image 3 As shown, the packaging structure of the brittle board of the present invention mainly includes an upper cover 1 , a plurality of intermediate layers 2 and a base 3 . Among them, an upper cover 1 is installed on the top of the middle layer 2, which is a flat structure; a plurality of middle layers 2 are stacked between the base 3 and the upper cover 1, and the upper edge surface is provided with a number of accommodating Groove 21, groove 22 and information storage device 23, and the bottom edge surface is provided with a plurality of protrusions 24; Base 3, located at the bottom under the middle layer 2, has accommodating groove 31, groove 32 and information storage device 33, the bottom of which has several openings 34, which can be used for handling equipment such as stackers.

[0031] see Figure 4 As shown, the intermediate layer 2 of the present invention is provided with a number of accommodation grooves 21, grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com