Phosphor coating method and arc tube

A technology of phosphors and light-emitting tubes, applied in the application of light-emitting paints, fluorescence, light sources, etc., can solve the problems of unevenness and unevenness of glass tubes, and achieve the effect of improving luminous efficiency and correcting unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0059] 1. The structure of double helix fluorescent lamp and luminous tube

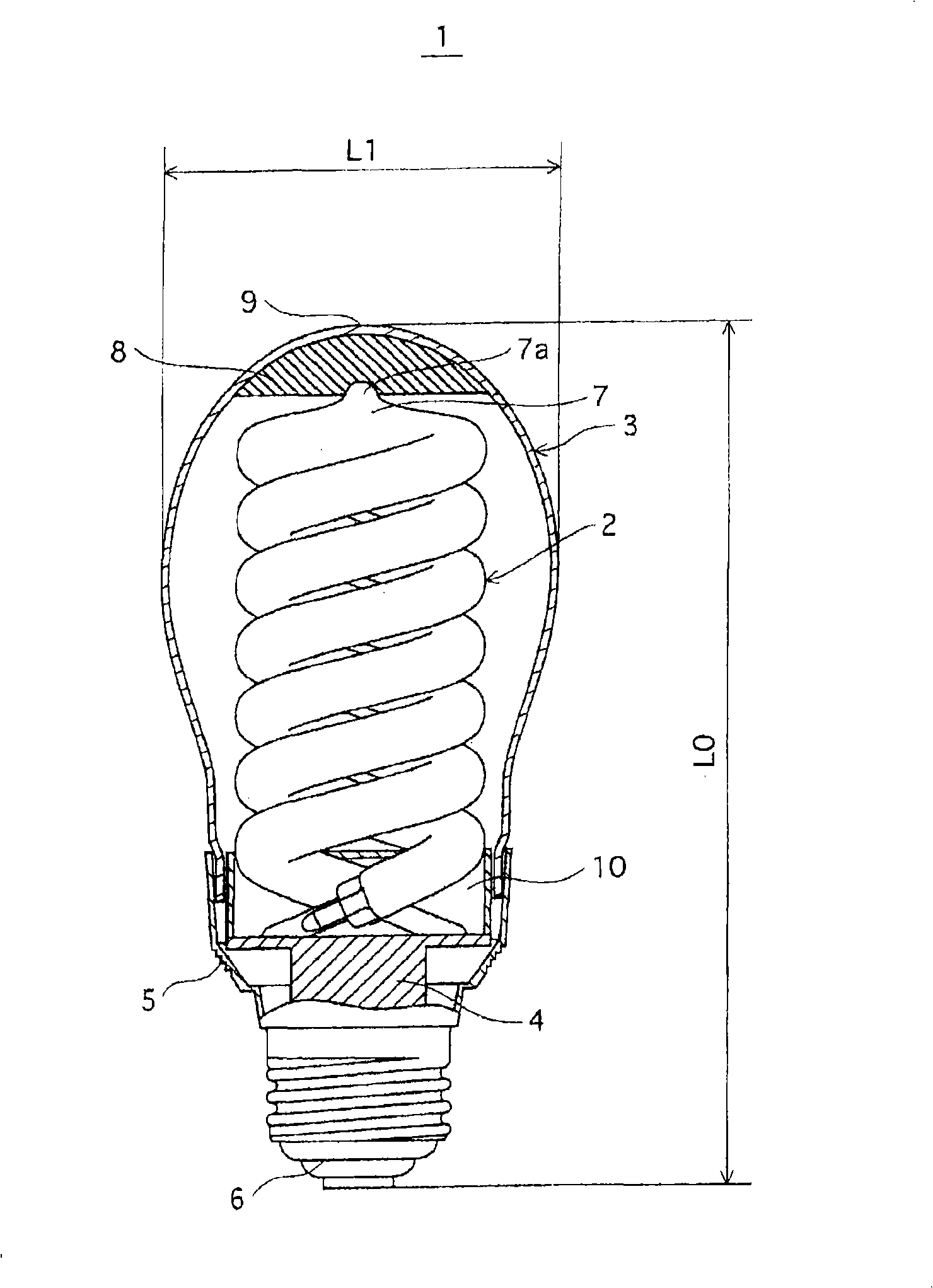

[0060] figure 1 It is a partially cutaway front view showing a double helix fluorescent lamp 1 (hereinafter, referred to as "the product A of the present invention") which is the first embodiment of the present invention.

[0061] like figure 1 As shown, the double-helix fluorescent lamp 1 includes: a double-helix luminous tube 2, an outer tube vacuum tube 3 covering the luminous tube 2, an electronic regulator 4, a housing 5 for accommodating the electronic regulator 4, and an E-shaped lamp. Seat 6. The double helix fluorescent lamp 1 is a kind of bulb-shaped 22W fluorescent lamp that replaces a normal 100W bulb.

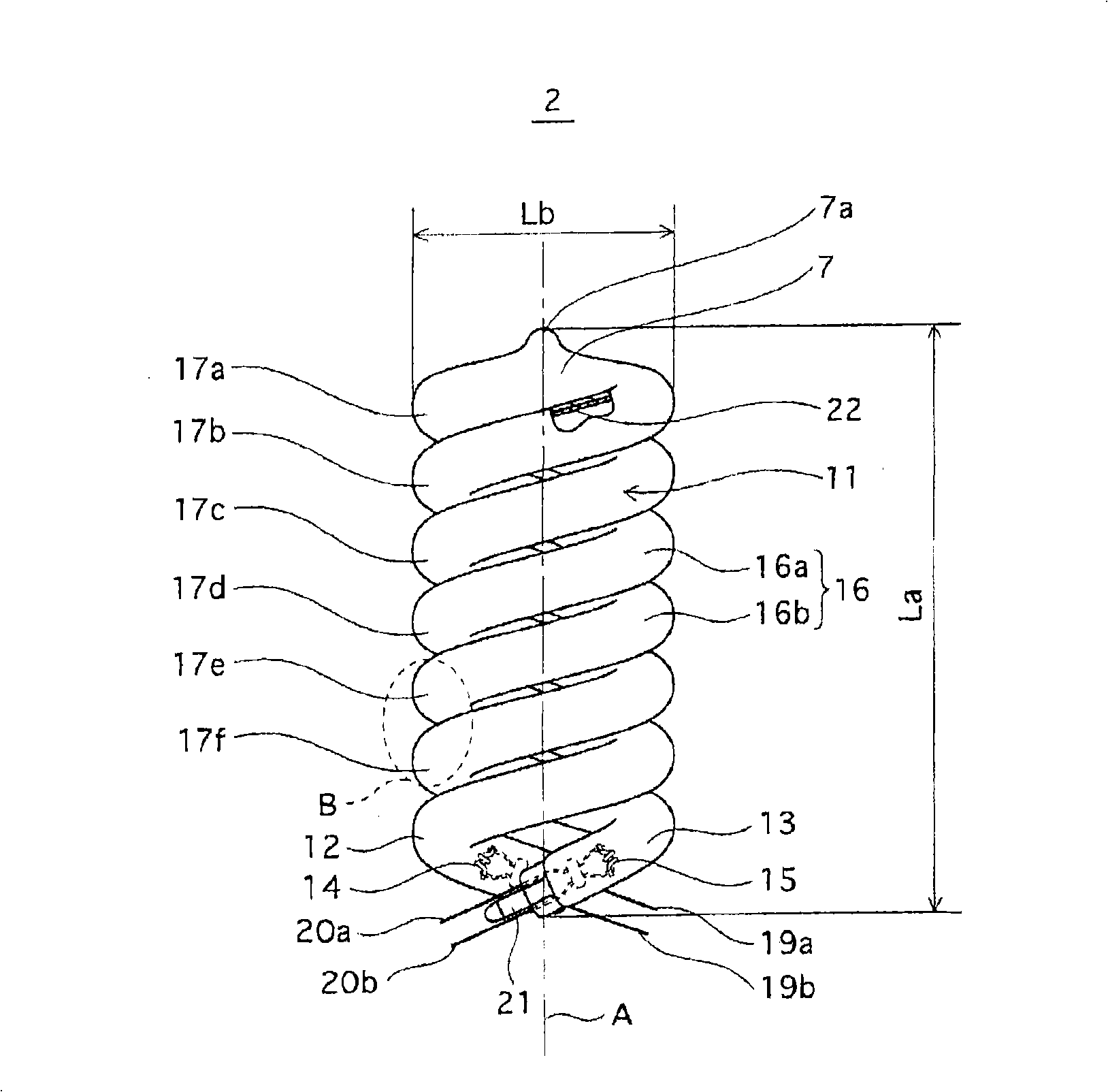

[0062] The luminous tube 2 has a double-helix shape, that is, a portion that rotates while maintaining a constant diameter in a vertical roll with a height like a soft-serve ice cream, and is formed at the turning-back portion (top) 7 at the front end. There is a convex portion 7a, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com