Nanometer coating composite paper and manufacturing method thereof

A nano-coating, composite paper technology, applied in the direction of coating, coated paper base paper, papermaking, etc., can solve the problem of no publicity, reduce production and management costs, good production adaptability, and simple process mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described.

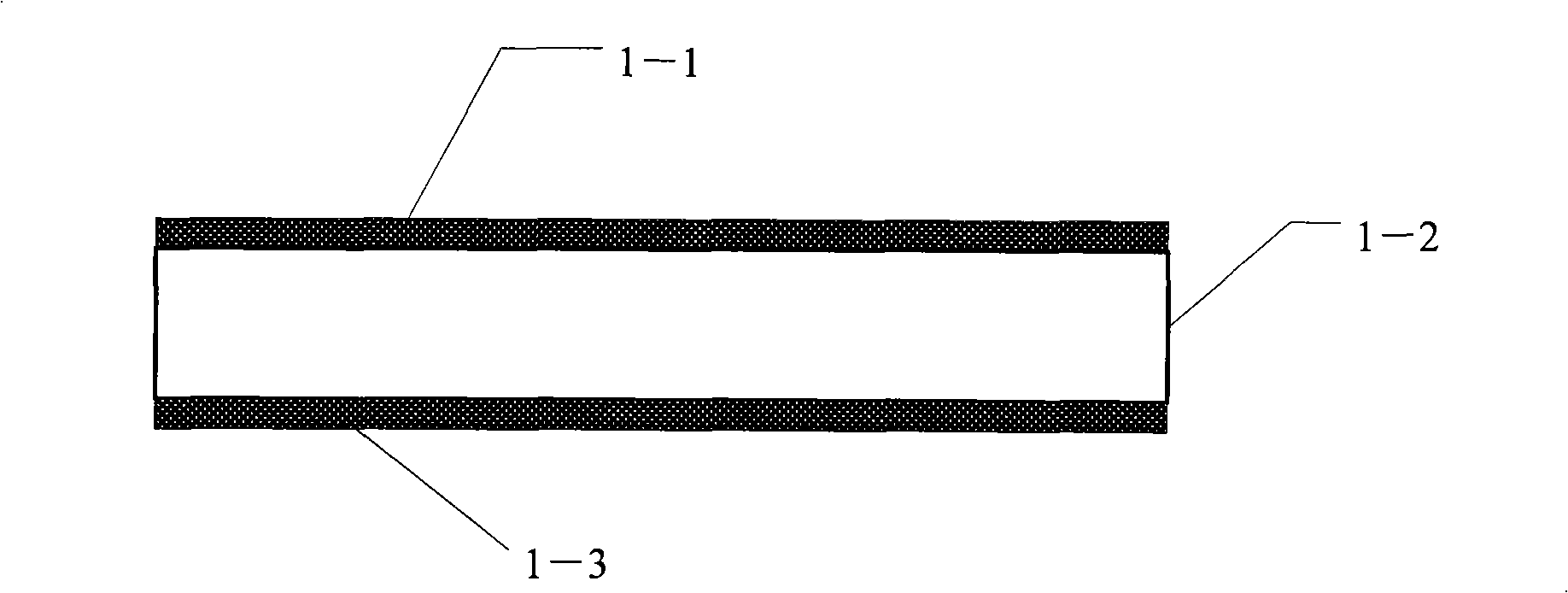

[0022] Such as figure 1 As shown, a nano-coated composite paper includes a paper substrate (1-2), at least one nanomaterial coating (1-1), and the nanomaterial is composited with the paper substrate, and the paper substrate At least one nanometer material coating (1-1 and 1-3 to 1-n) is formed to form a nanometer coating composite paper.

[0023] The paper substrate (1-2) of the above-mentioned nano-coated composite paper can be various papers made of various plant fibers;

[0024] The nano-materials of the above-mentioned nano-coating composite paper can be various nano-materials in various forms;

[0025] The nano-material coating (1-1 and 1-3 to 1-n) of the above-mentioned nano-coating composite paper can be single-sided of the paper substrate (1-2), or double-sided of the paper substrate (1-2) It can be single-layer (1-1 or 1-3) or multi-layer (1-1, 1-3...1-n).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com