Dropper for strong corrosive chemical agent

A chemical reagent and corrosive technology, applied in the field of chemical reagent tip dropper, which can solve the problems of chemical damage and corrosion of tip tip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

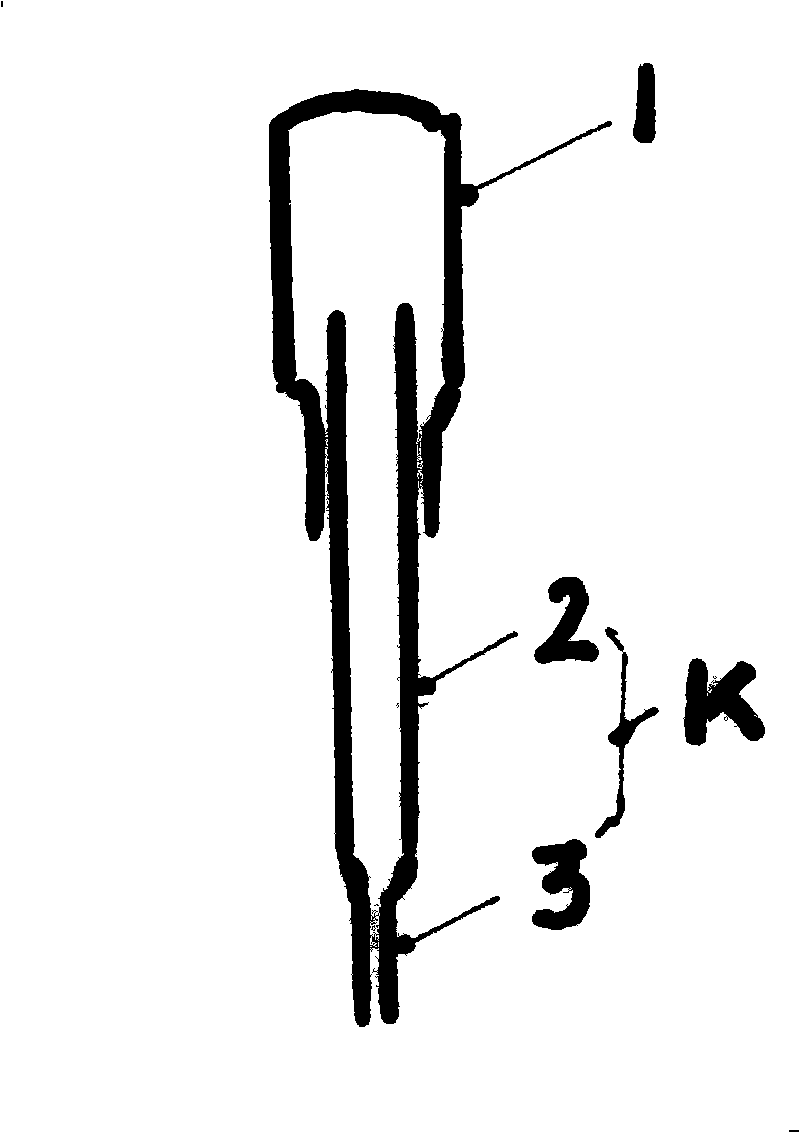

[0022] like figure 1 shown:

[0023] It is not difficult to see that the dropper in the tip dropper of the prior art product is composed of a single-head dropper K, and the rear (top) of the single-head dropper K is completely open in the cavity of the tip 1 , as long as there is residual chemical agent that has not been used up in the drip chamber 2 that constitutes the single-head dropper K, there is a possibility that the residual chemical agent will flow back into the cavity of the pipette tip 1 . ——Because, under normal circumstances, the user of the tip dropper will temporarily tilt the dropper hole of the tip dropper upward or horizontally for various reasons during the gap period of continuous work. Or for a period of time, in this way, it is inevitable that the above-mentioned residual chemical agent will flow back into the cavity of the tip 1 from the drop chamber 2, and this possibility is very large.

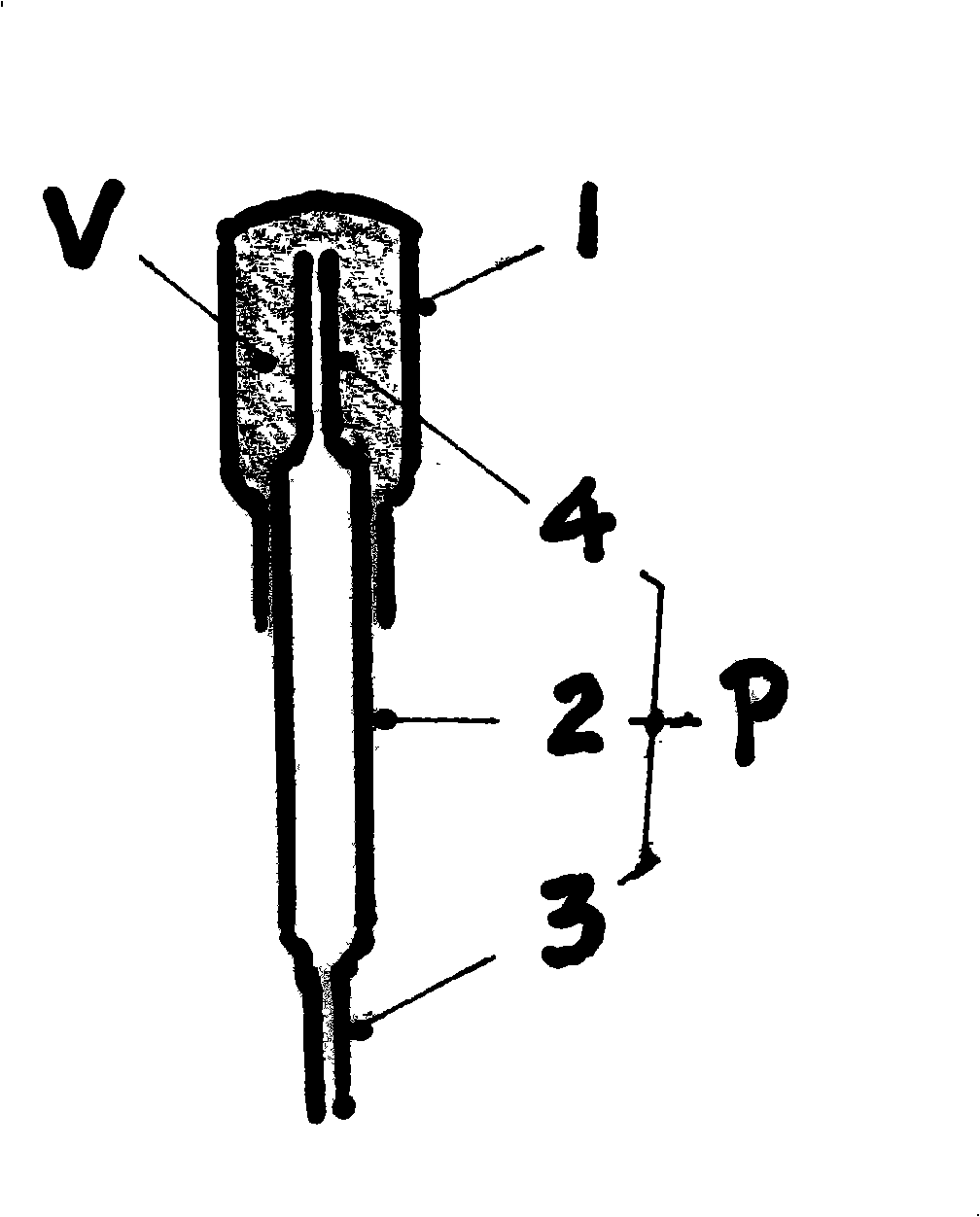

[0024] like figure 2 shown:

[0025] Obviously, since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com