Improved stereo weaving decorative laminate and method of manufacture

A decorative layer and pressing board technology, which is applied in lamination, decorative arts, lamination devices, etc., can solve the problems of unfavorable weaving process, inability to stick the woven surface material firmly, and reduce toughness, etc., and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

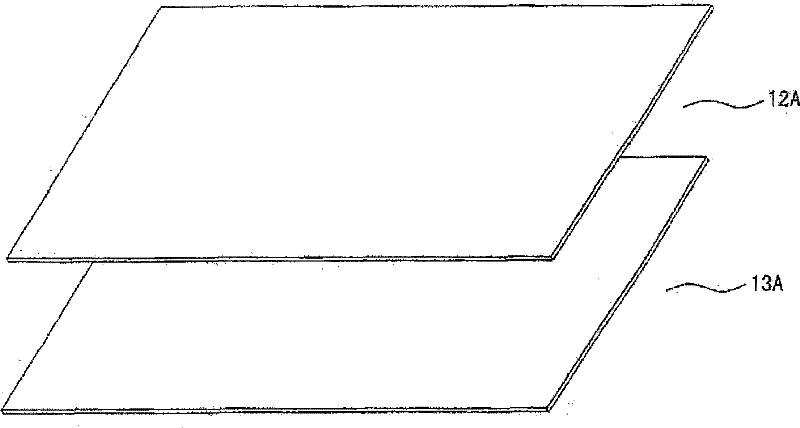

[0046] Figure 1AShown is sheet material 12A for weaving the surface of a high pressure decorative laminate. The sheet material 12A can be plant fiber sheets (such as bamboo, wood, cloth, etc. sheets), metal sheets, thread materials or other synthetic material sheets (including plastic sheets, simulated synthetic materials). A piece of explosion-proof cracking paper (or fiber cloth) 13A is placed below the sheet material 12A, and its upper surface is coated with glue. The glue on the upper surface of the explosion-proof cracking paper (or fiber cloth) 13A is selected to match the sheet material 12A, so that the thin sheet material 12A and the explosion-proof cracking paper (or fiber cloth) 13A can be firmly pasted together. The present invention is by sticking a piece of explosion-proof cracking paper (or fiber cloth) 13A below the sheet material 12A, so that other quality materials other than the plant fiber sheet can also be used as the material of forming the weaving surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com