Vacuum degreasing sintered quenching integrated furnace

A vacuum degreasing and integrated technology, applied in the direction of quenching devices, furnaces, muffle furnaces, etc., can solve the problems of high energy consumption, non-application, and low production efficiency, and achieve the goals of compact overall structure, simplified production process, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

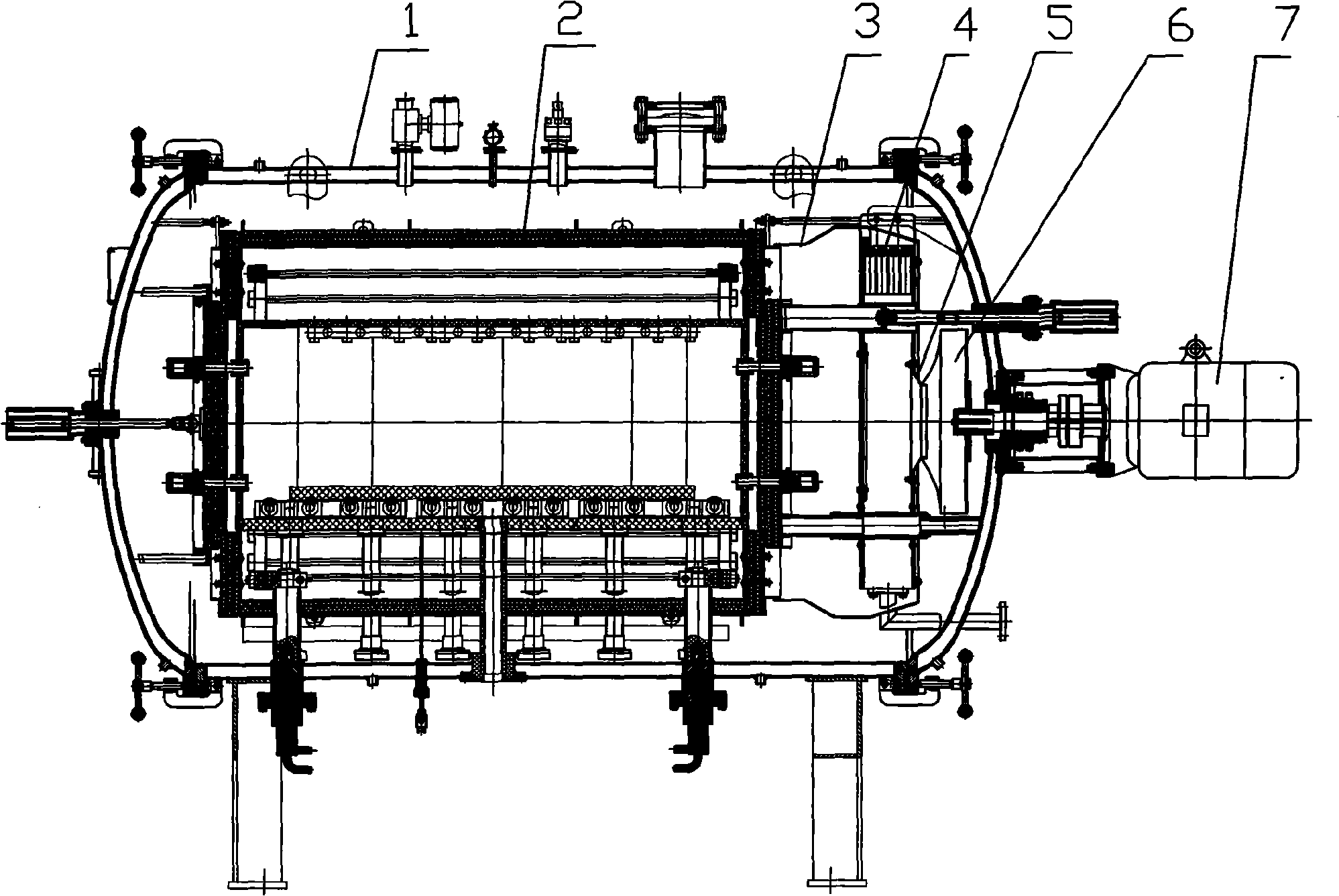

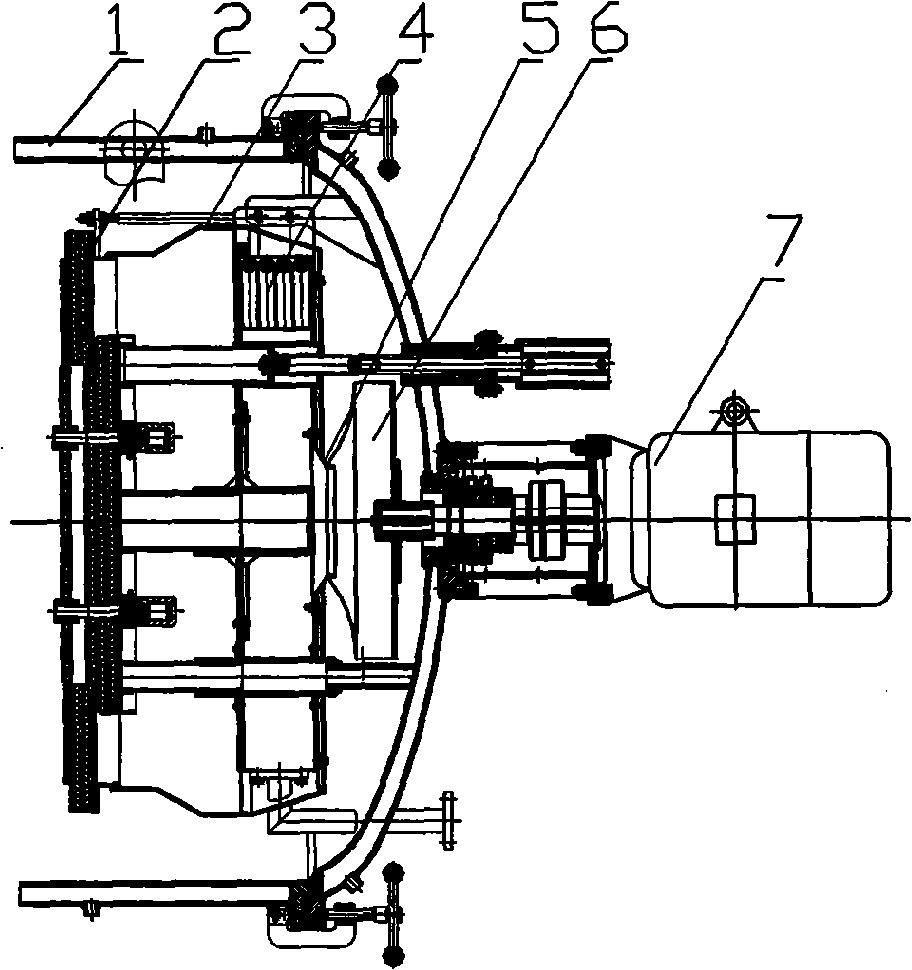

[0011] see figure 1 and figure 2 , the furnace body 1 is a horizontal single-chamber (or double-chamber) front and rear double-door structure. , Outer layer 6mm), the hearth 2 is a square shape, which is composed of soft carbon felt and hard carbon felt composite heat shield, graphite heating element, and sealed graphite box for degreasing from outside to inside. The furnace doors at both ends (that is, both ends of the furnace) are equipped with furnace insulation doors. When the furnace door is closed, the inner insulation doors seal the furnace ends to prevent the heat from radiating in the furnace. The insulation door of the furnace is equipped with a dynamic sealing opening and closing device, which opens to form an air duct during rapid cooling. The heating element is connected to the outside through the water-cooled electrode, which ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap