Cooling device for constant speed wheel of high speed enamelling machine

A technology of cooling device and fixed speed wheel, which is applied in the direction of conductor/cable insulation, electrical components, circuits, etc., can solve the problems of reducing product DV value, affecting production efficiency, and the outer paint film is easy to be scratched, so as to improve Cooling effect, effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

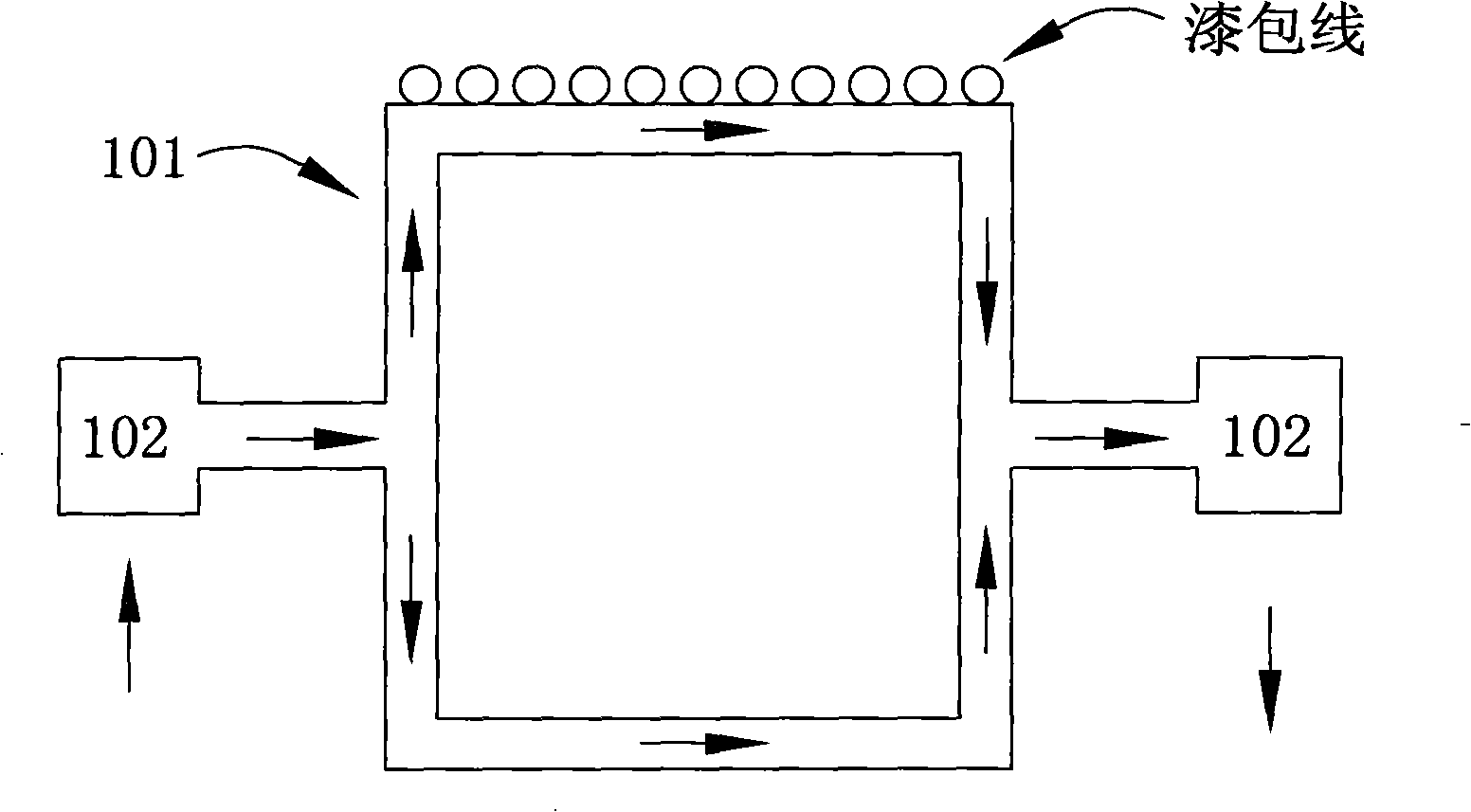

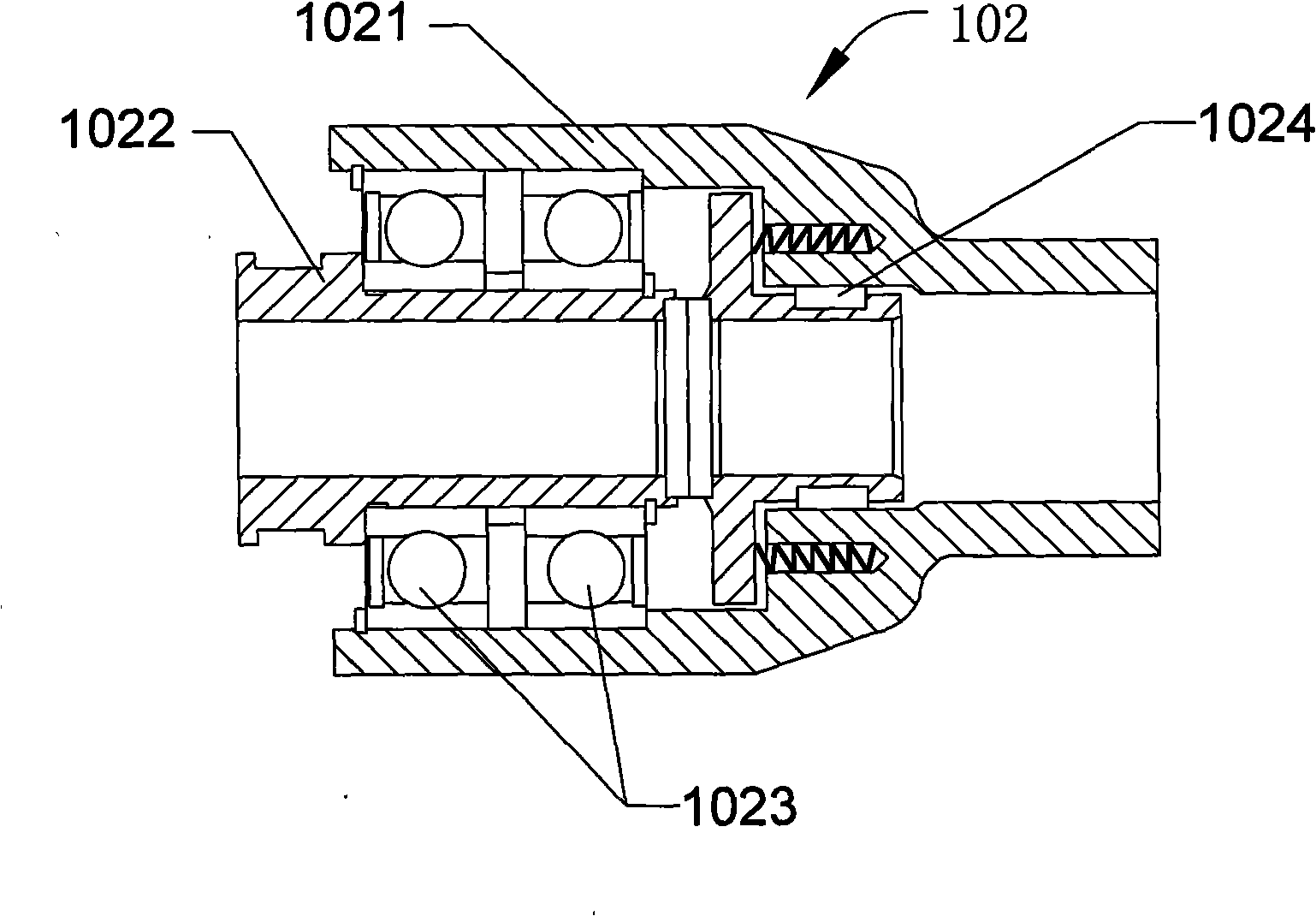

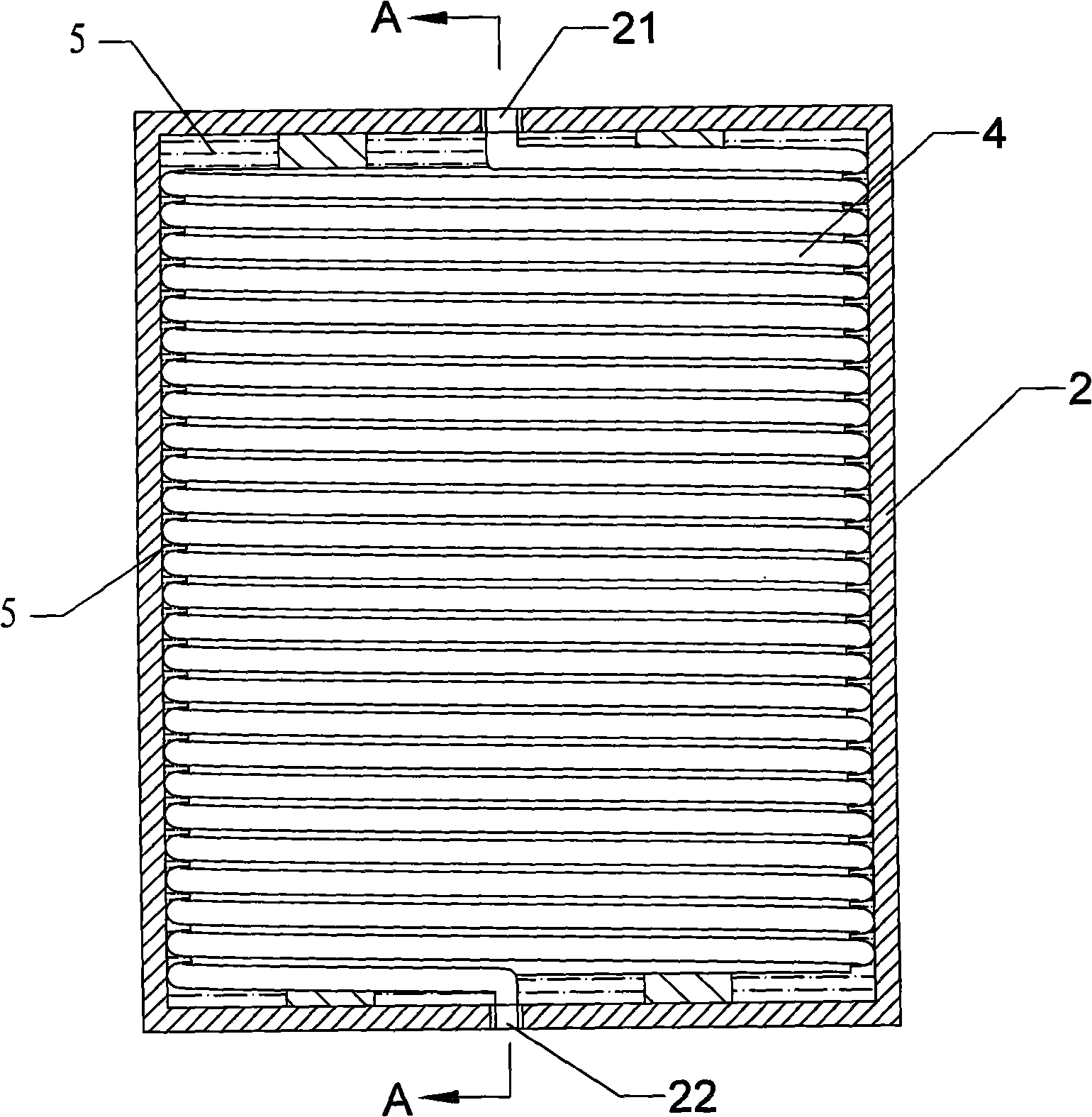

[0031] See attached image 3 and Figure 4 As shown, the high-speed enamelling machine fixed speed wheel 101 cooling device of the present invention includes a fixed speed wheel 101 and a rotary joint 102, and the fixed speed wheel 101 includes an inner tube 1 and an outer tube 2, and the outer tube 2 and the inner tube 1 are mostly used A rolled steel pipe or an aluminum pipe with better thermal conductivity is preferred, and the outer pipe 2 is sleeved on the inner pipe 1 by setting positioning ends at both ends thereof. One end wall of the outer tube 2 has a water inlet 21, and the other end has a water outlet 22. When in use, because the fixed speed wheel 101 drives the enameled wire to rotate, therefore, the water inlet 21 and the water outlet 22 places should be equipped with Rotary joint 102, the structure of this type of rotary joint 102 is specifically figure 2 As shown and explained above, one end of the rotary joint 102 can rotate with the fixed wheel 101, and th...

Embodiment 2

[0033] see Figure 5 , Image 6 As shown, the present embodiment is another embodiment of the fixed speed wheel 101 of the high-speed enamelling machine according to the present invention, and its basic structure is consistent with that of the first embodiment, so it is omitted here. The difference is:

[0034] The inner wall of the outer tube 2 is provided with a circular arc groove 23 matching the heat exchange tube 4, and the heat exchange tube 4 is embedded in the circular arc groove 23, which can realize a better fit of the heat exchange tube 4 in the heat exchange cavity 3. Positioning can also increase the contact surface between the heat exchange tube 4 and the outer tube 2 and improve the heat exchange efficiency. At the same time, heat-conducting silicone grease is provided between the arc groove 23 and the wall of the heat exchange tube 4, which further improves the heat exchange efficiency of the heat exchange tube 4 through the tube wall of the outer tube 2 and t...

Embodiment 3

[0036] see Figure 7 , Figure 8 As shown, the present embodiment is the third embodiment of the fixed speed wheel 101 of the high-speed enamelling machine according to the present invention, and its basic structure is consistent with that of Embodiment 1, so it is omitted here. The difference is:

[0037] The heat exchange tube 4 is serpentinely wound on the outer wall of the inner tube 1, so that the water flow flows back and forth from the surface of the inner tube 1 along the axial direction to the two end walls of the tube, and also makes the heat exchange tube 4 communicate with the enameled wire through the outer tube 2. Better heat exchange effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com