Hollow polymers capsules with meso-porous shell and preparation method thereof

A polymer, mesopore-containing technology, applied in microcapsule preparations, microsphere preparation and other directions, can solve the problems of high synthesis cost and achieve the effects of small size, simple process and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

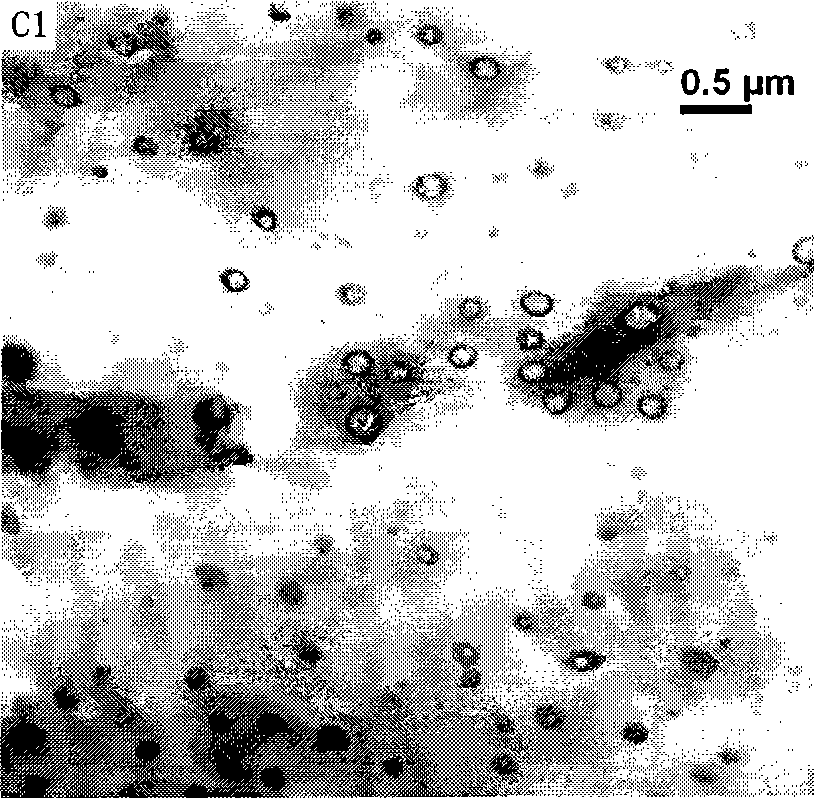

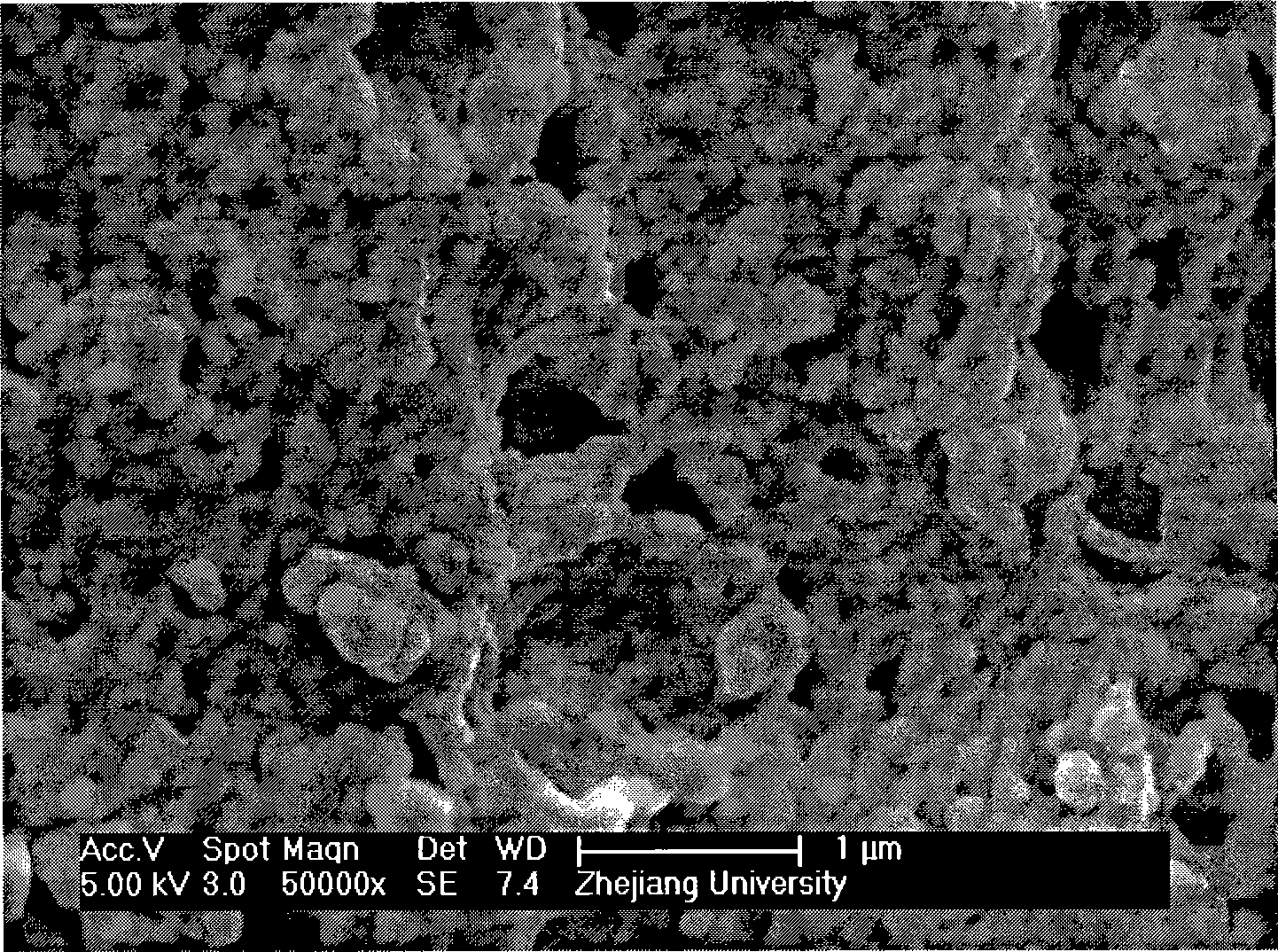

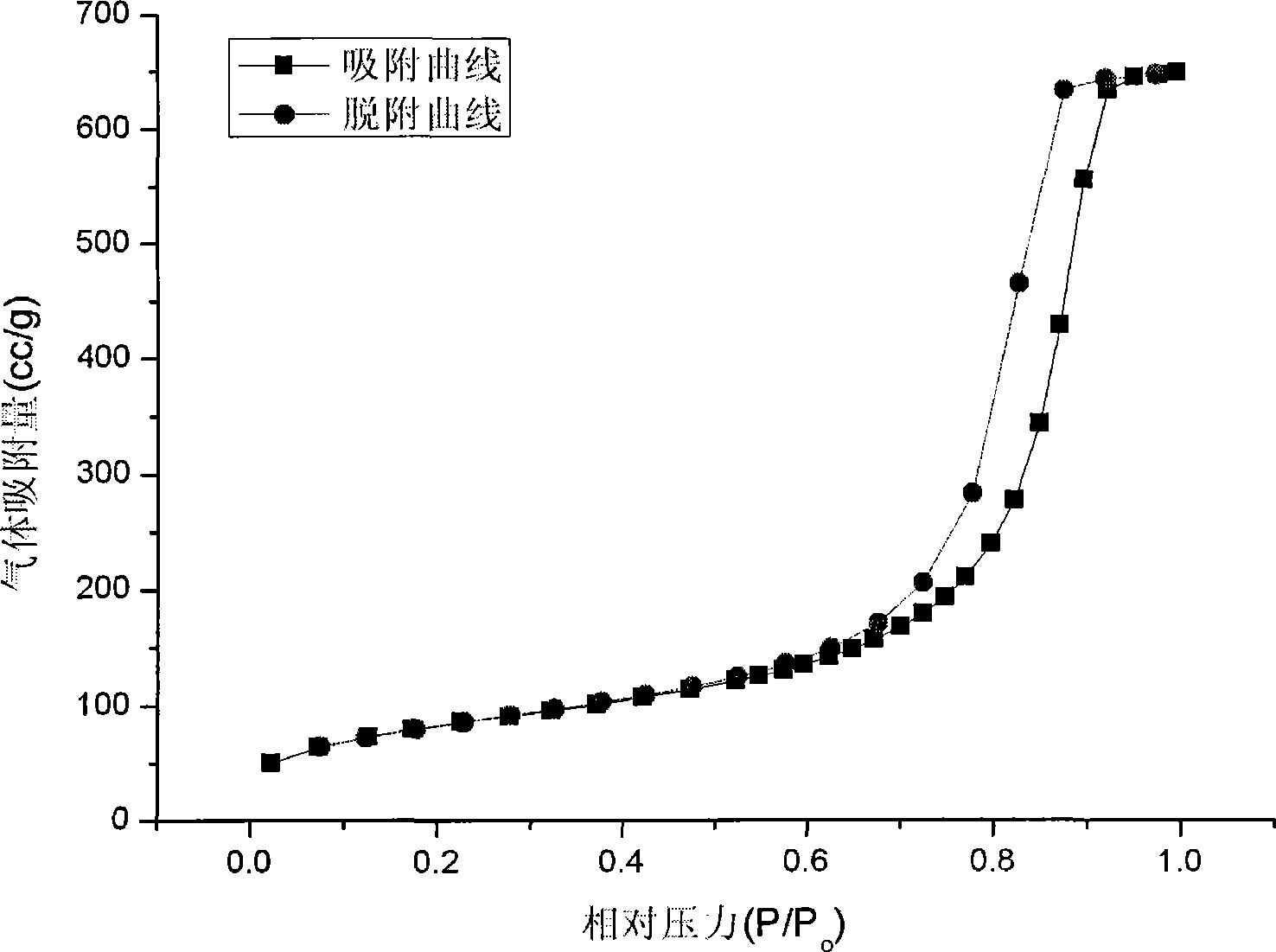

[0021] 0.36g of SDS and 1.8g of PEO 40 NE was dissolved in 36 g deionized water. The pH of the aqueous phase was fixed at 7 with equal amounts of ammonium dihydrogen phosphate and disodium hydrogen phosphate. Then 0.2g HD and 0.4g poly(methyl methacrylate-b-methacryloxypropyl trimethylsilane), wherein the average molecular weight of methyl methacrylate segment is 15000, methacryloxypropyl The average molecular weight of the trimethylsilane segment is 40,000, which is dissolved in 4 g of toluene. Then use an ultrasonic pulverizer (KS600) to ultrasonicate for 15 minutes at 0° C. under the condition that the intensity is 75%. SDS0.36g was added after the ultrasound, and finally the obtained miniemulsion was transferred to a 250ml medical bottle and sealed for preservation. Add NH to the sample after 4 days 4 Oh. After 5 days, the above four groups of samples were demulsified and centrifuged with methanol, washed with methanol and centrifuged again, and repeated three times t...

Embodiment 2

[0023] 0.36g of SDS and 1.8g of PEO 40 NE was dissolved in 36 g deionized water. The pH of the aqueous phase was fixed at 7 with equal amounts of ammonium dihydrogen phosphate and disodium hydrogen phosphate. Then 0.2g HD and 0.4g poly(methyl methacrylate-b-methacryloxypropyl trimethylsilane), wherein the average molecular weight of methyl methacrylate segment is 7000, methacryloxypropyl The average molecular weight of the trimethylsilane segment is 40,000, which is dissolved in 4 g of toluene. Then use an ultrasonic pulverizer (KS600) to ultrasonicate for 15 minutes at 0° C. under the condition that the intensity is 75%. SDS0.36g was added after the ultrasound, and finally the obtained miniemulsion was transferred to a 250ml medical bottle and sealed for preservation. Add NH to the sample after 4 days 4 Oh. After 5 days, the above four groups of samples were demulsified and centrifuged with methanol, washed with methanol and centrifuged again, and repeated three times to...

Embodiment 3

[0025] Mix 1.8g of SDS and 1.8g of PEO 40 NE was dissolved in 36 g deionized water. The pH of the aqueous phase was fixed at 7 with equal amounts of ammonium dihydrogen phosphate and disodium hydrogen phosphate. Then 0.2g HD and 0.4g poly(methyl methacrylate-b-methacryloxypropyl trimethylsilane), wherein the average molecular weight of methyl methacrylate segment is 15000, methacryloxypropyl The average molecular weight of the trimethylsilane segment is 40,000, which is dissolved in 4 g of toluene. Then use an ultrasonic pulverizer (KS600) to ultrasonicate for 15 minutes at 0° C. under the condition that the intensity is 75%. Add 0.36 g of SDS after the ultrasound, and finally transfer the obtained miniemulsion to a 250 ml medical bottle, and keep it sealed. Add NH to the sample after 4 days 4 Oh. After 5 days, the above four groups of samples were demulsified and centrifuged with methanol, washed with methanol and centrifuged again, and repeated three times to wash away ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com