Light diffusion lamination plate

A light diffusion and laminate technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of complicated assembly steps of backlight modules and no light diffusion effect, and achieve the effect of good light diffusion and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

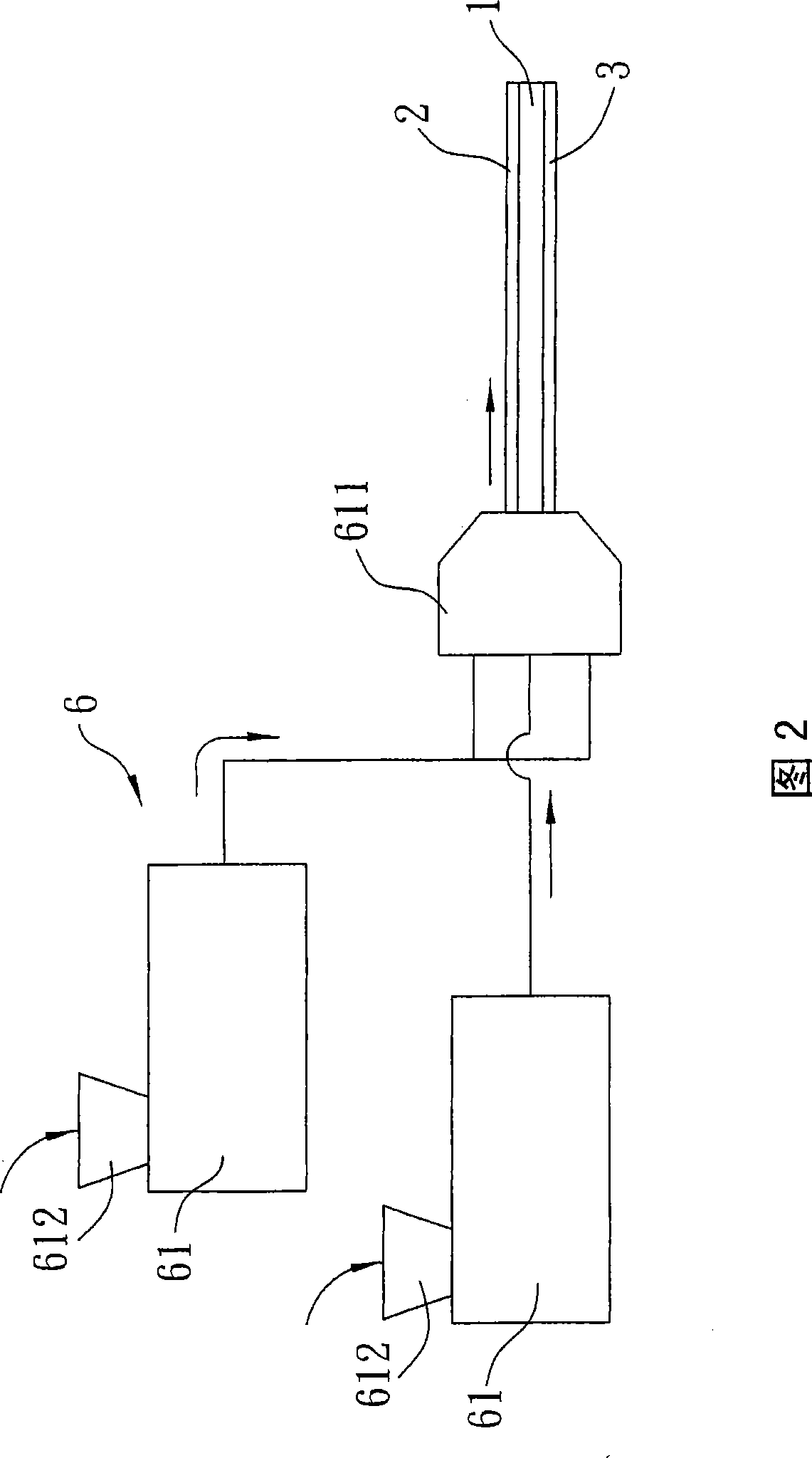

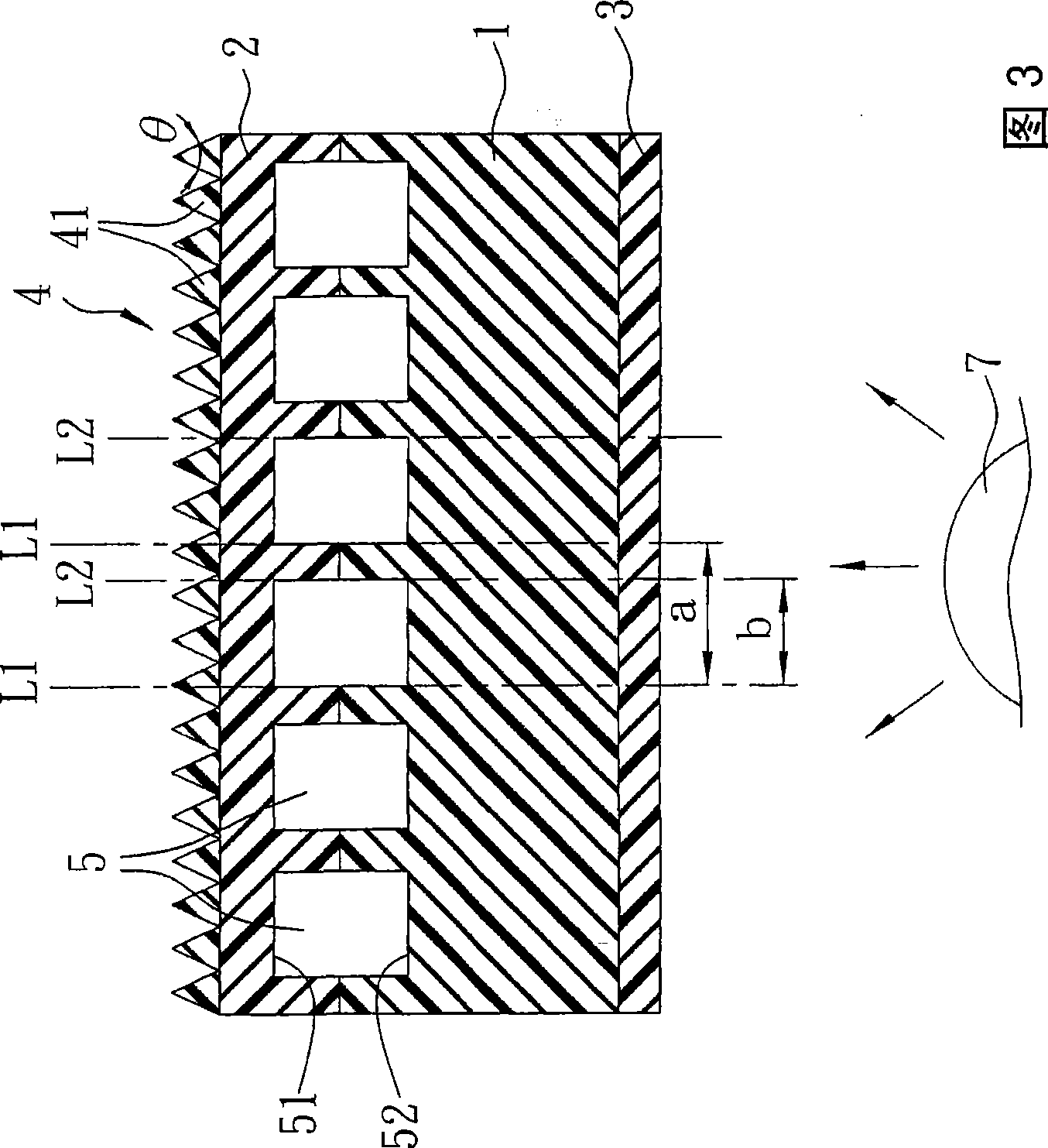

Embodiment 1

[0096] The material of the protective layer 3 of the present embodiment is mainly polymethyl methacrylate resin, and the first resin layer 1 is 3 weight parts of the organic microparticle light diffusing agent that is mixed with silicone resin in 100 weight parts of polycarbonate resins, and this second The resin layer 2 is polymethyl methacrylate resin. The molding method is to use the co-extrusion molding device 6 of the three-layer hollow plate, the cylinder temperature is kept at 200-250°C, the mold temperature is 240-260°C, the vacuum degree of the degassing part is 20mmHg, and the special-shaped die lips with parallel quadrilaterals are used. Extrude the die head 611, and adjust the discharge amount of the first resin layer 1, the second resin layer 2 and the protective layer 3 molding materials while co-extruding and forming, and finally, coat the surface of the second resin layer 2 with UV curable acrylic Resin is used, and the microlens layer 4 in the shape of a prism...

Embodiment 2

[0103] Referring to FIG. 3 , the difference between Embodiment 2 of the light-diffusing laminate of the present invention and the Embodiment 1 lies in that the light-diffusing agent in the first resin layer 1 of Embodiment 2 is used in an amount of 1 part by weight.

Embodiment 3

[0105] Referring to Fig. 6, the difference between Embodiment 3 of the light-diffusing laminated board of the present invention and Embodiment 1 is that the thicknesses of the protective layer 3, the first resin layer 1 and the second resin layer 2 in Embodiment 3 are respectively 0.05mm , 1.5 mm and 1.3 mm, and the strip-shaped hollow chamber 5 of embodiment 3 is only surrounded by the second resin layer 2 and does not touch the first resin layer 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com