Intermediate demagnetizing machine for magnetic selected iron ore powder

A demagnetization machine and intermediate frequency technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of unsatisfactory demagnetization effect, waste of energy output, etc., and achieve high work efficiency, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

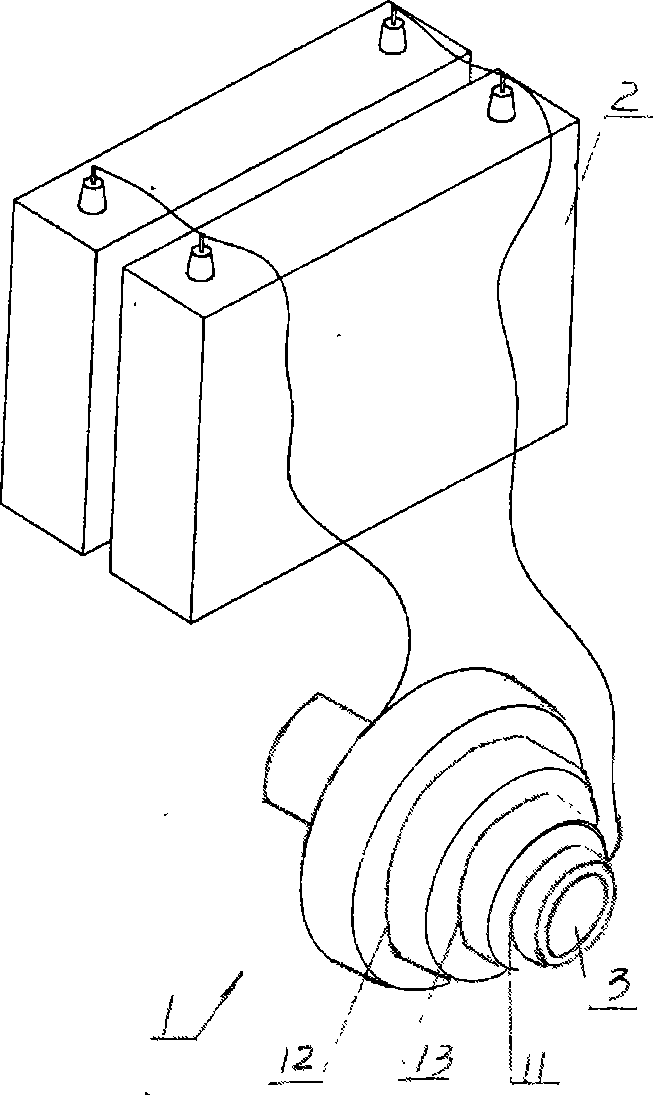

[0017] see figure 1 , the figure shows the appearance structure schematic diagram of an embodiment of the hollow demagnetization component in the demagnetizer for magnetic separation of iron ore powder proposed by the present invention. The hollow demagnetization component includes a coil 1 whose inner surface is a hollow cylindrical body 11, an outer surface is a stepped cylindrical body, and a capacitor component 2 that is electrically connected to the coil 1, and is axially inserted into the hollow cylindrical body 11 with both ends outward. Extended insulating tubing 3. The outer surface of the coil 1 is provided with two steps 12 and 13. The steps 12 and 13 are formed by reducing the number of turns of the coil 1. The combination of the coil 1 and the capacitor component 2 can form resonant electromagnetic waves. The magnetic field strength that can be provided by the hollow cylinder 11 in it is gradually attenuated from the step 12 to the step 13. When iron ore powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com