Tire retreading casting molding method

A molding and sand molding technology, which is applied in the field of casting molding of CPP controllable pitch propeller blades, can solve the problems of high cost, time-consuming and laborious, and the quality of castings cannot be guaranteed, and achieve the effect of reasonable design, rapid modeling and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

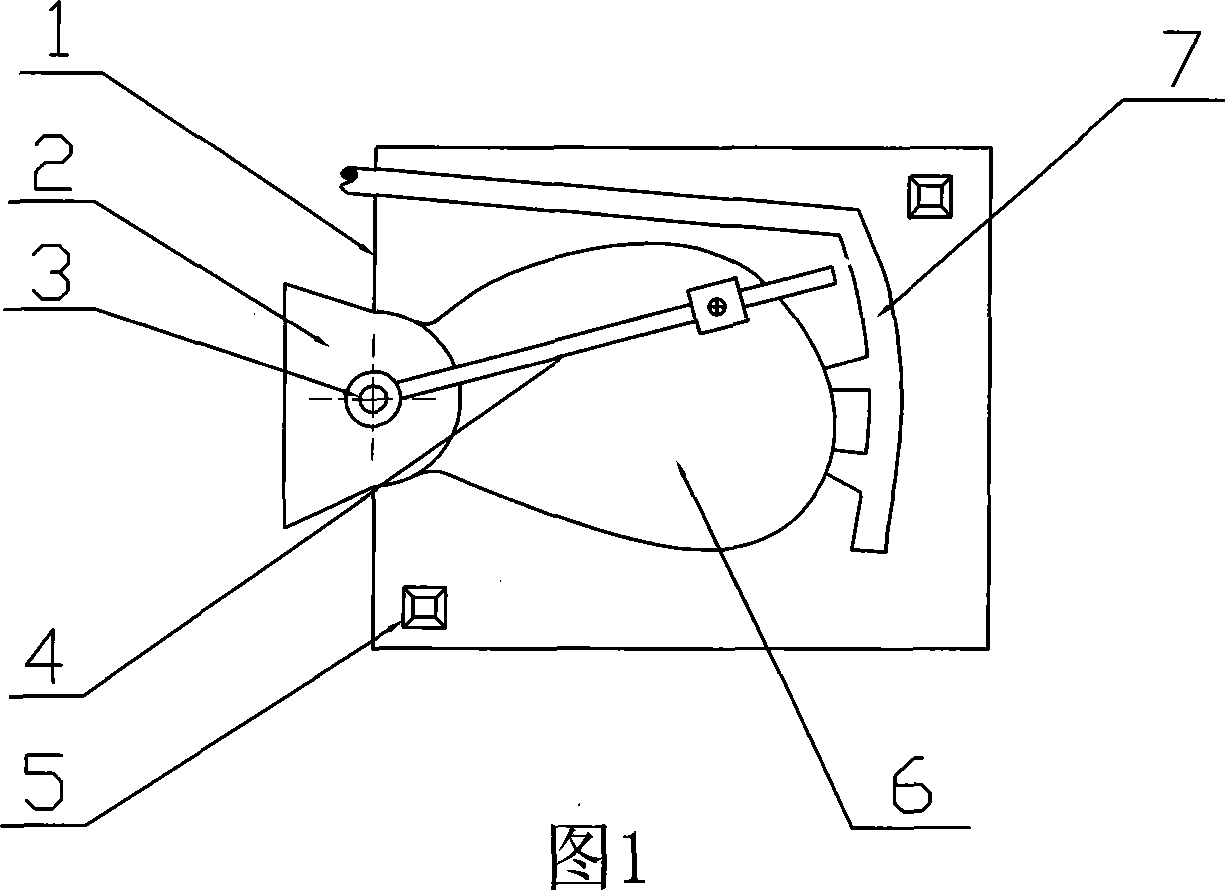

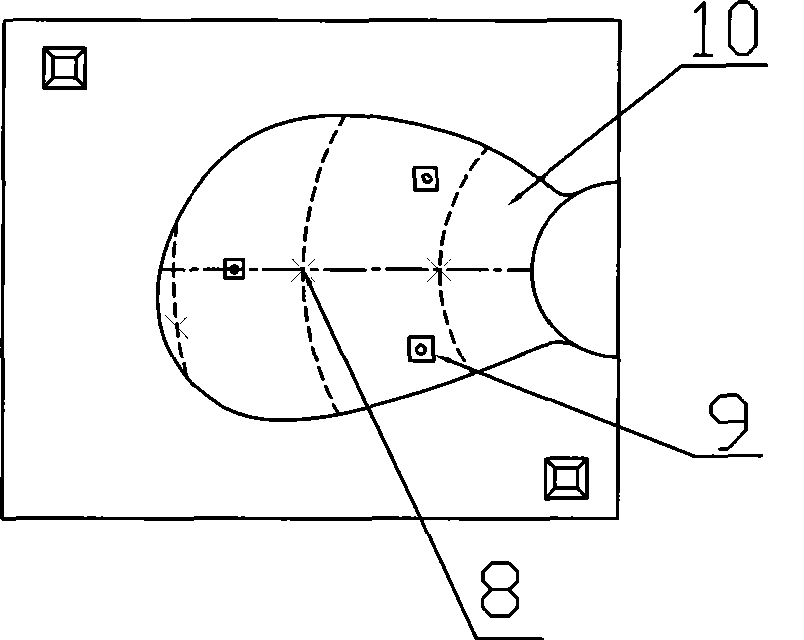

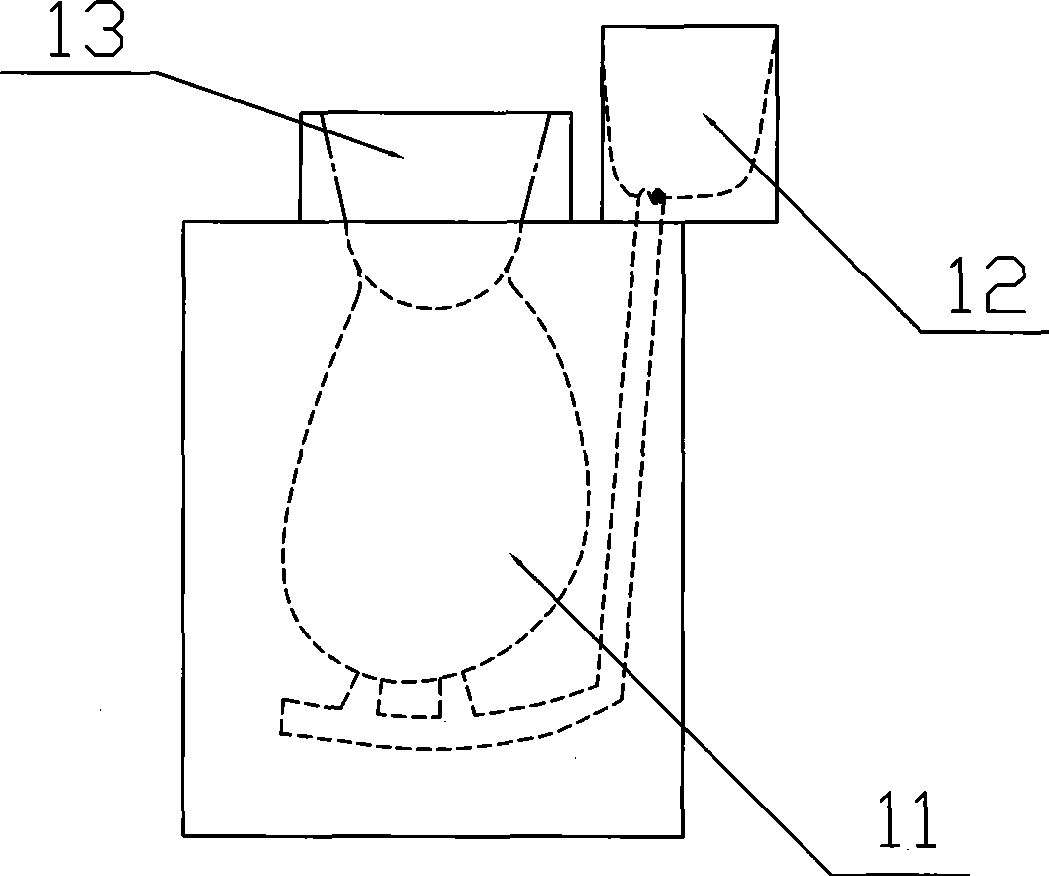

[0039] Such as Figure 1 ~ Figure 4 Shown is a retreading casting method. The technological process includes aligning the plane of the flange wood mold with the semicircular opening of the square flask on the adjusted square flask. Position the measurement datum point of the pitch gauge at the center point of the flange wood mold, and use the center longitudinal template to check. Test the maximum and minimum values, the widest and narrowest cross-sections (using cross-section templates), and the reserved space for the pouring system, so that the upper and lower boxes eat as much sand as possible.

[0040] After the measurement reference point is determined, the pressure surface of the blade is made from the inside out with the water glass sand (using pitch gauge, cross-section model, and longitudinal model), and a position for the positioning box cone is reserved. Blow CO 2 After hardening, the pressure surface is polished and the leaf profile is drawn with the cross-sectional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com