Main paper-packing system for ream packer

A packaging system and paper package technology, applied in paper product packaging, wrapping paper bending devices, packaging, etc., can solve the problems of large randomness, difficult maintenance, low production efficiency, etc., and achieve stable machine operation and high degree of automation , good packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] 2 to 15 illustrate an embodiment of the present invention.

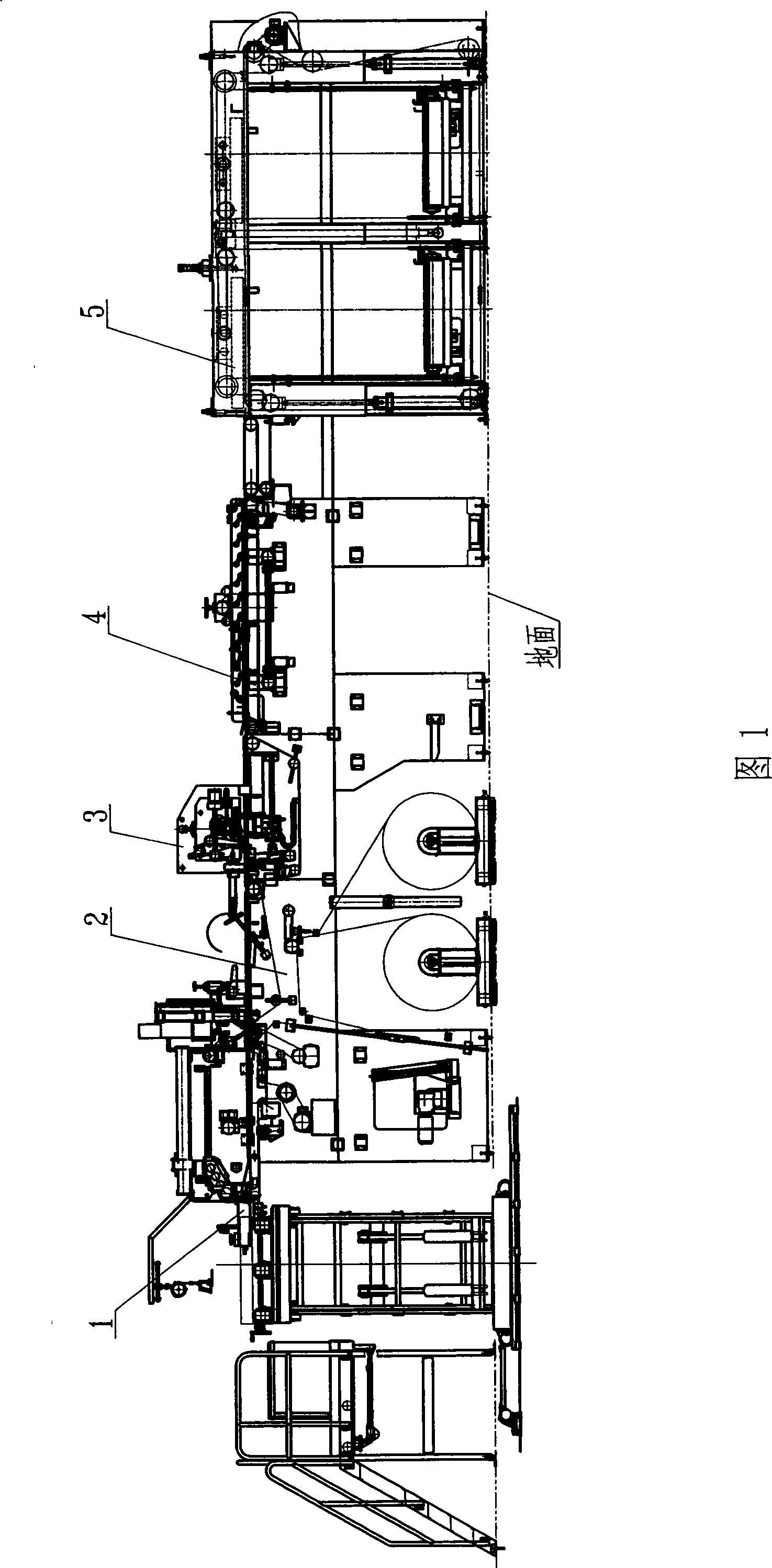

[0023] As shown in Figure 1, it includes a paper feeding system 1, a wrapping paper system 2, a main packaging system 3, a folding packaging system 4, and a stacking system 5, and each system is connected in turn. The present invention is the main packaging system 3 .

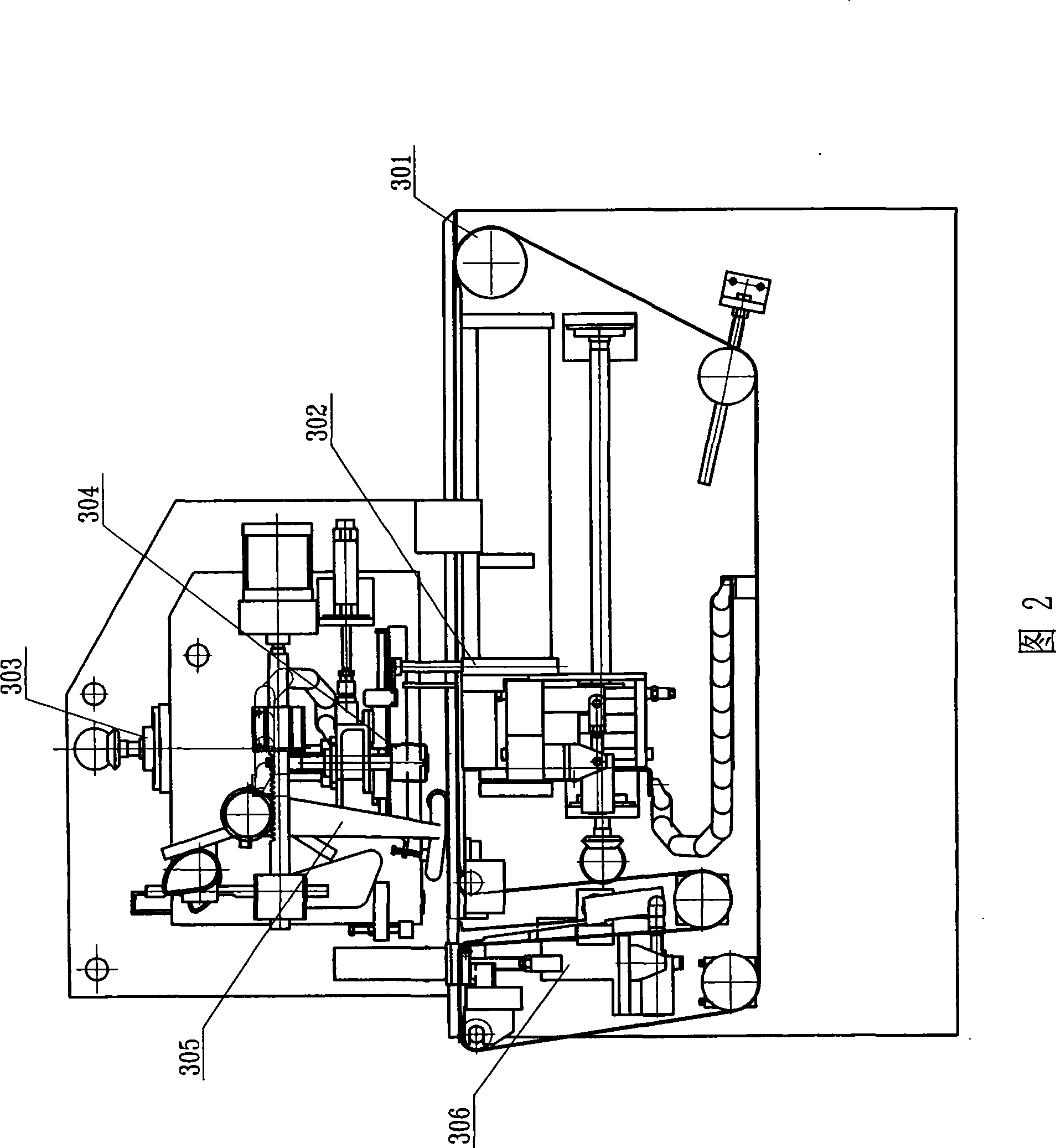

[0024] As shown in FIG. 2 , the main packaging system 3 includes a 3# belt conveying device 301 , a paper retaining device 302 , an up and down adjusting device 303 , a paper suction device 304 , a rolling device 305 , and a paper top device 306 . The main packaging system completes the packaging of the ream body.

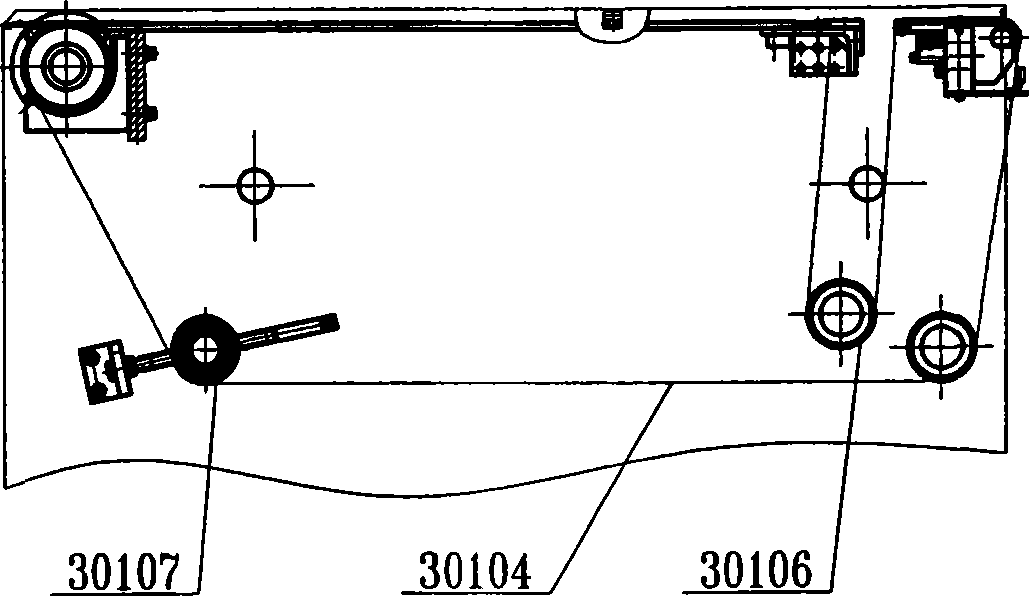

[0025] Such as image 3 , Figure 4 As shown, the 3# belt conveying device 301 includes a servo reduction motor 30101, a driving roller 30102, a supporting bar 30103, a conveyor belt 30104, a drum pulley 30105, a reversing roller 30106 and a tensioning device 30107. The driving roller 30102 is supported by two bearings installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com