Electrode slurry dispersing method

An electrode slurry and dispersion technology, which is applied in the direction of mixing methods, electrode manufacturing, chemical instruments and methods, etc., can solve the problems of poor uniformity of slurry, large volume, and unfavorable electrochemical performance of batteries, so as to improve electrochemical performance, Good coating uniformity and the effect of eliminating particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Use a mixing bucket with stirring blades to disperse the negative electrode slurry of the company's 053448 battery, and the motor drives the stirring blades of the mixing bucket to stir the negative electrode slurry in the bucket for 5 hours; then place the stirred negative electrode slurry in ultrasonic dispersion Ultrasonic dispersion treatment was carried out in the machine, the ultrasonic frequency was 50MHz, and the temperature of the negative electrode slurry was kept at 30°C during the ultrasonic dispersion treatment. After 2 hours of ultrasonic dispersion treatment, the negative electrode slurry after ultrasonic dispersion treatment was coated on an aluminum foil with a thickness of 16 μm.

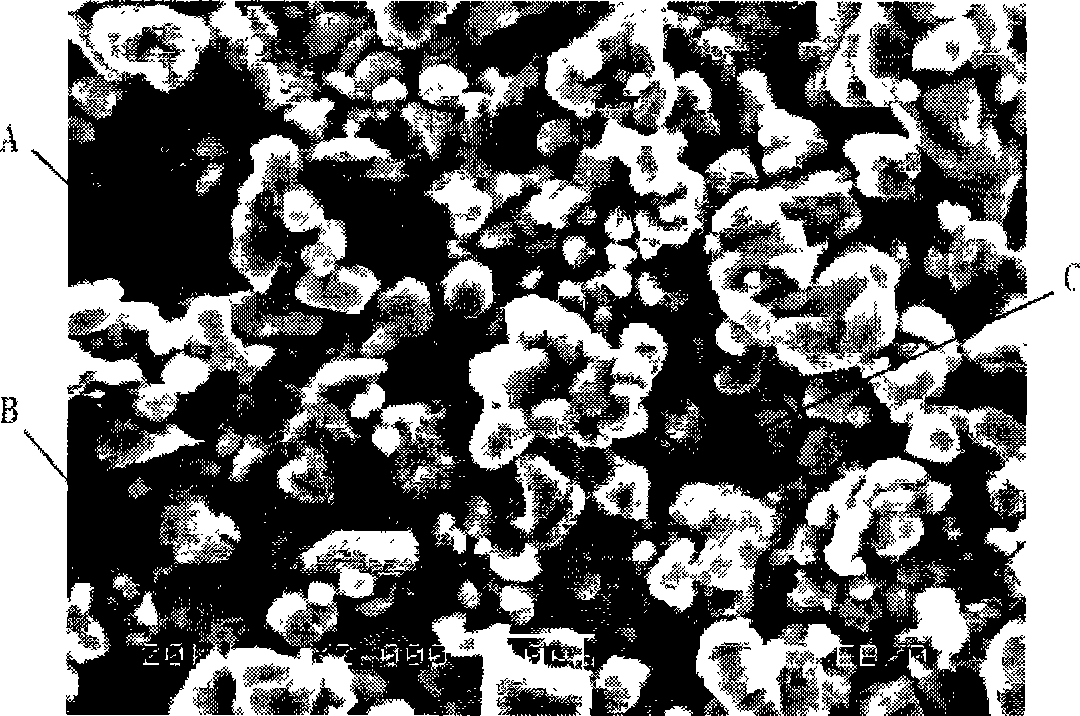

[0023] The above-mentioned aluminum foil coated with negative electrode slurry is dried, and the negative electrode slurry layer is subjected to SEM analysis, figure 2 For the obtained SEM photographs. Compared with the comparative example, figure 2 There is no such thing...

Embodiment 2

[0028] According to Example 1, the negative electrode slurry of the 053448 model battery is dispersed, and the difference from the dispersion process of Example 1 is that the stirring time of the negative electrode slurry in the mixing tank is 2h; the ultrasonic frequency is 21MHz; During the treatment, the temperature of the negative electrode slurry was kept at 35° C.; the ultrasonic dispersion treatment time was 15 minutes.

[0029] The negative electrode slurry after the dispersion treatment is measured and calculated according to Example 1, and the average value of the negative electrode slurry surface density on each row of samples is 21.539mg / cm 2 , with a standard deviation of 0.162.

Embodiment 3

[0031] According to Example 1, the negative electrode slurry of the 053448 model battery is dispersed, and the difference with the dispersion treatment process of Example 1 is that the stirring time of the negative electrode slurry in the mixing tank is 12h; the ultrasonic frequency is 60MHz; During the treatment, the temperature of the negative electrode slurry was maintained at 40° C.; the ultrasonic dispersion treatment time was 6 h.

[0032] The negative electrode slurry after the dispersion treatment is measured and calculated according to Example 1, and the average value of the negative electrode slurry surface density on each row of samples is 21.613mg / cm 2 , with a standard deviation of 0.143.

[0033] Comparing the standard deviation data of the surface density of the negative electrode slurry on the samples in each embodiment and the comparative example shows that, compared with the comparative examples, after the negative electrode slurry is carried out mechanical s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com