Pneumatic feeding machine for plastic jetting-moulding machine

A feeder and injection molding machine technology, applied in the field of pneumatic feeders for injection molding machines, can solve the problems of easy clogging of filter elements, lower quality of color products, and high power consumption, and achieve the effects of improving quality, obvious energy-saving effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

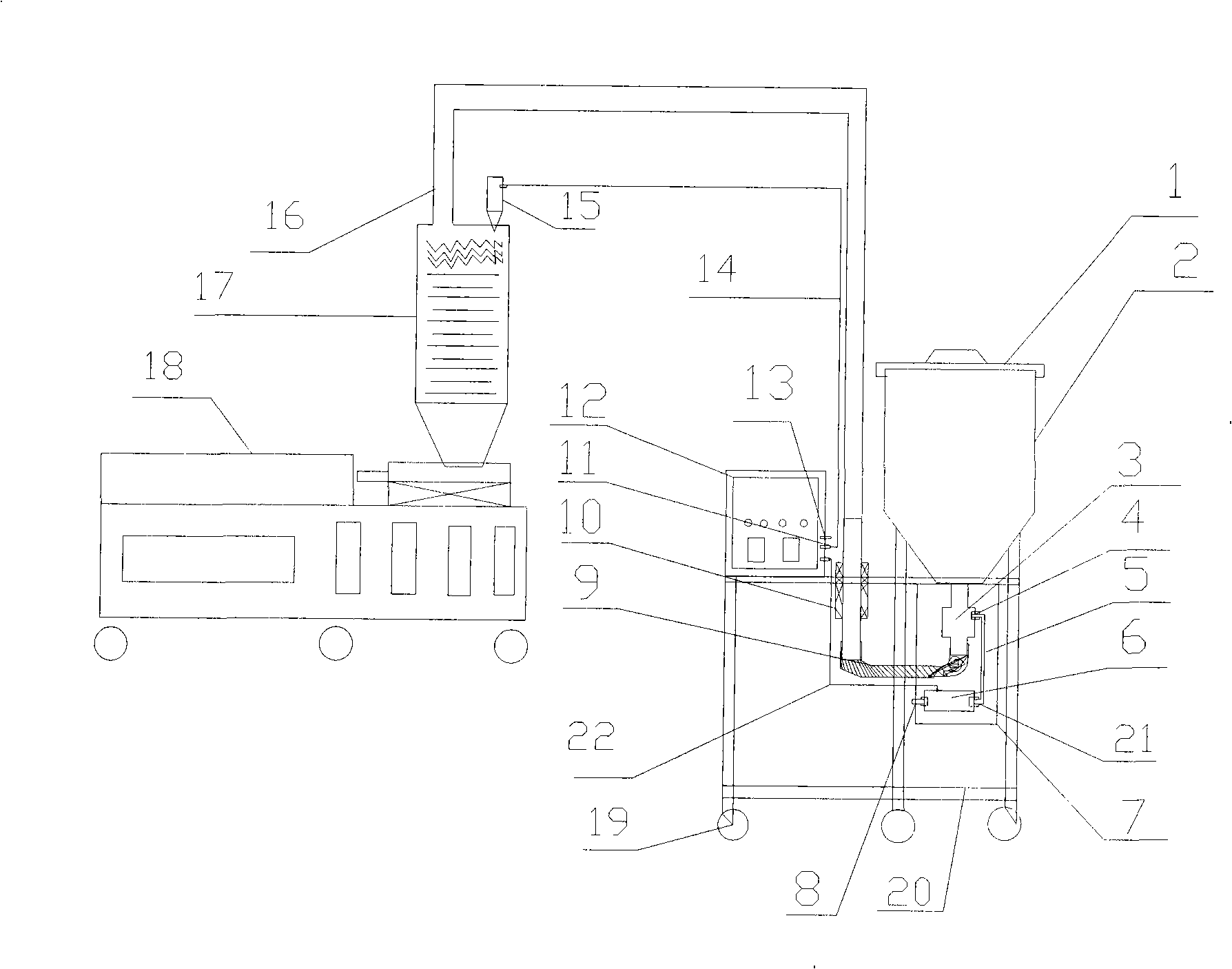

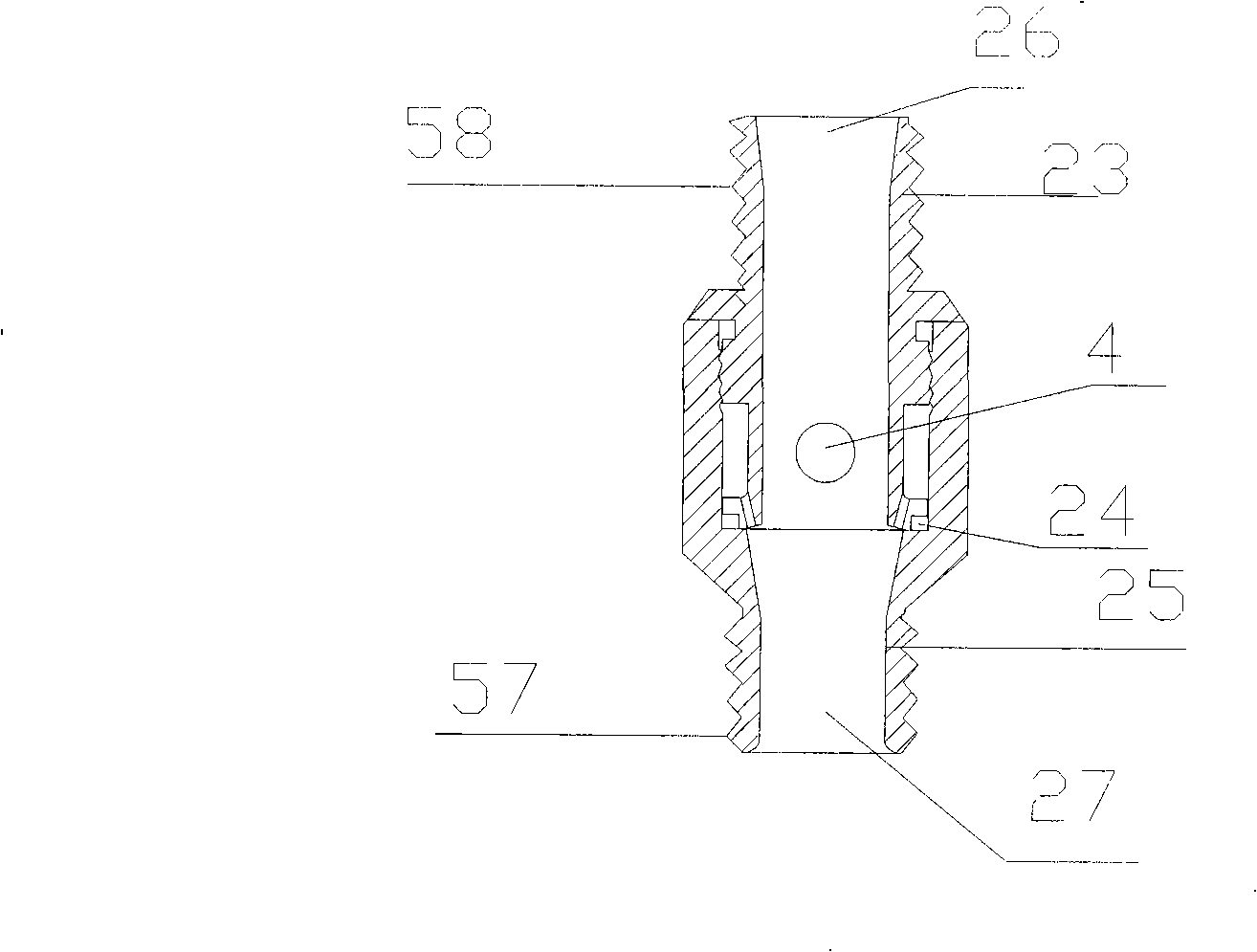

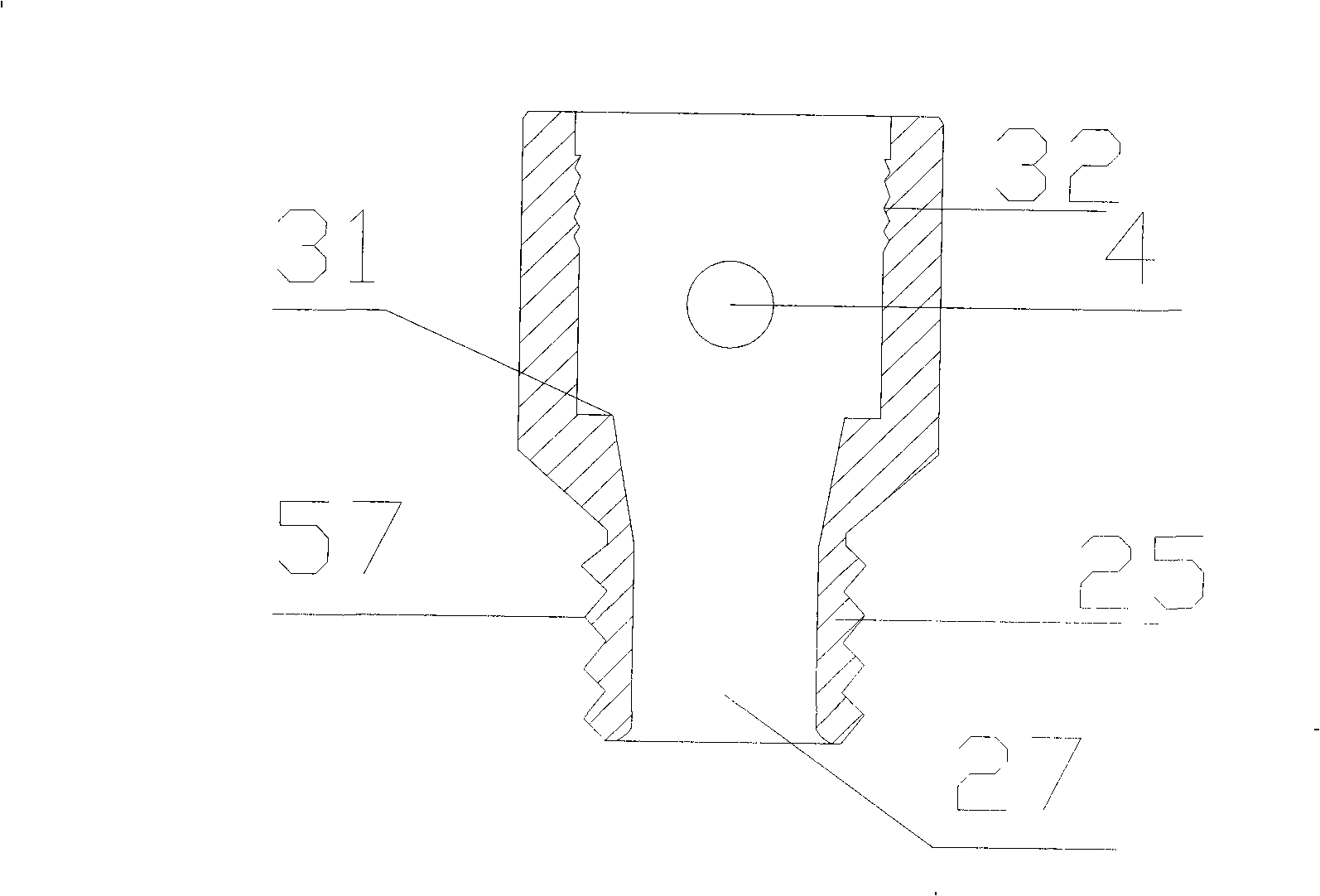

[0022] figure 1 It is a structural schematic diagram of a pneumatic feeder for injection molding machine according to the present invention, including a feeder bracket 20 with a fixed pulley 19, an electric control box 12 and a feeder hopper 2 are respectively provided on the left and right sides of the upper surface of the feeder bracket 20, The top of the feeder hopper 2 is provided with a feeder hopper cover 1, and the bottom of the feeder hopper 2 is connected to the feeder 3 located in the feeder protective box 7, and the feeder inlet 4 of the feeder 3 passes through the feeder hose 5 and The solenoid valve air outlet 21 of solenoid valve 6 is connected, and the solenoid valve air inlet 8 of solenoid valve 6 is located on the side wall of feeder protective box 7, and solenoid valve 6 is connected with electric control box 12 by solenoid valve connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com