RTM molding method and device

A molding method and molding device technology, applied in textiles, papermaking, fiber processing, etc., can solve problems such as poor fluidity, long time, and aggravated resin gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0197] In each of the above-mentioned embodiments, the size of the metal mold on the molding surface (cavity surface) is 1500 mm x 1200 mm x 3 mm in depth, and as the reinforcing fiber base material, 8 layers of torayca T700 fabric BT70-30 manufactured by Toray Co., Ltd. are used. (300g / m 2 ) laminates, as the resin, high-speed curing epoxy resin (main agent: "Epikoto" 828 (epoxy resin manufactured by Yuhua Shell Epoxy Co., Ltd.); curing agent: Toray Co., Ltd. blend (blend) TR- C35H (imidazole derivative)) can be molded well and quickly even for relatively large molded products. It should be noted that when the resin injection pressure is 0.7MPa, the time for the resin to completely impregnate the substrate is 5 minutes or less, which can be shortened to 1 / 5-1 / 10 or 1 / 5-1 / 10 or less.

[0198] 8 to 12 show the RTM molding method and apparatus according to the second embodiment of the present invention. FIG. 11 shows a schematic configuration diagram of an example of a moldi...

Embodiment 2

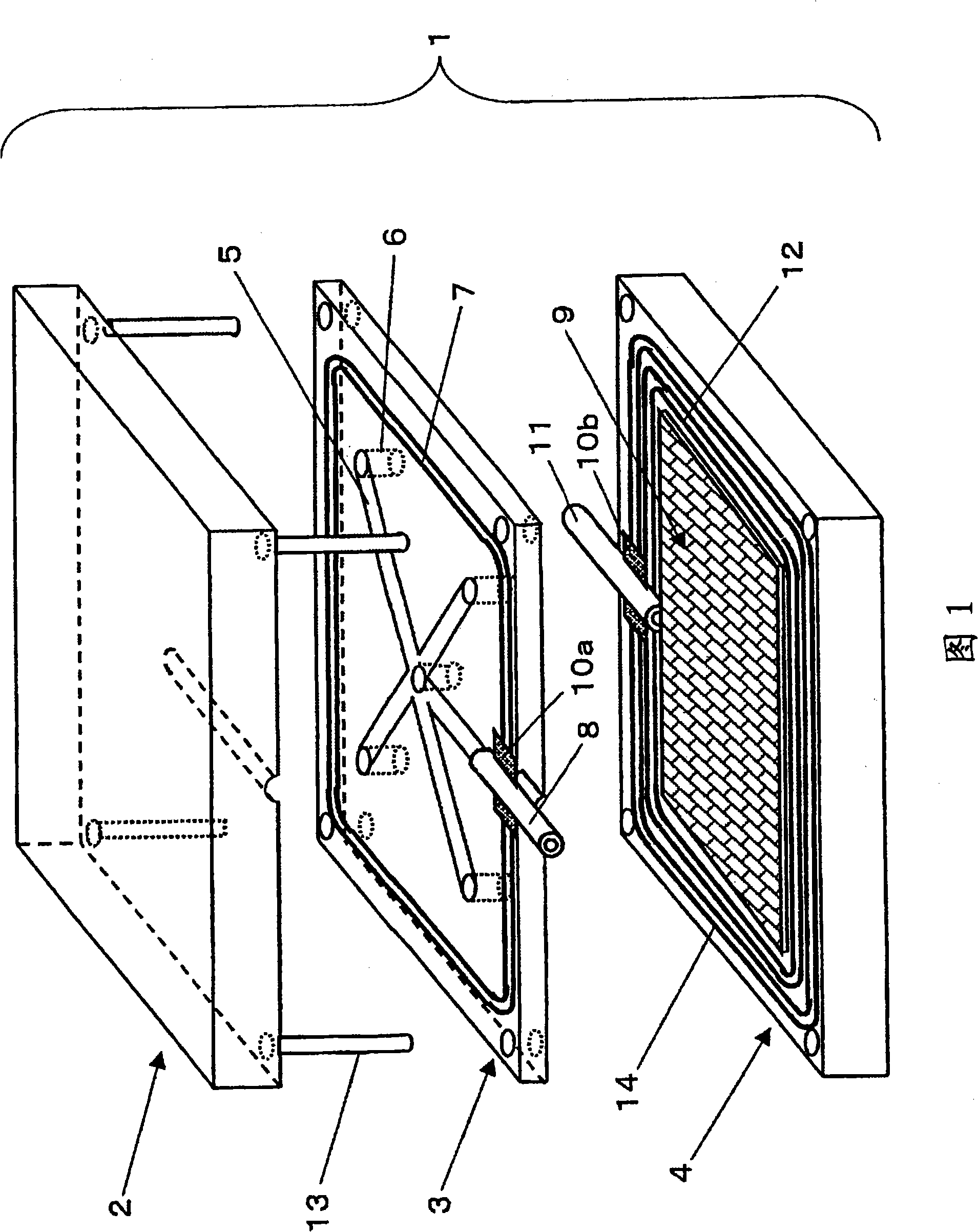

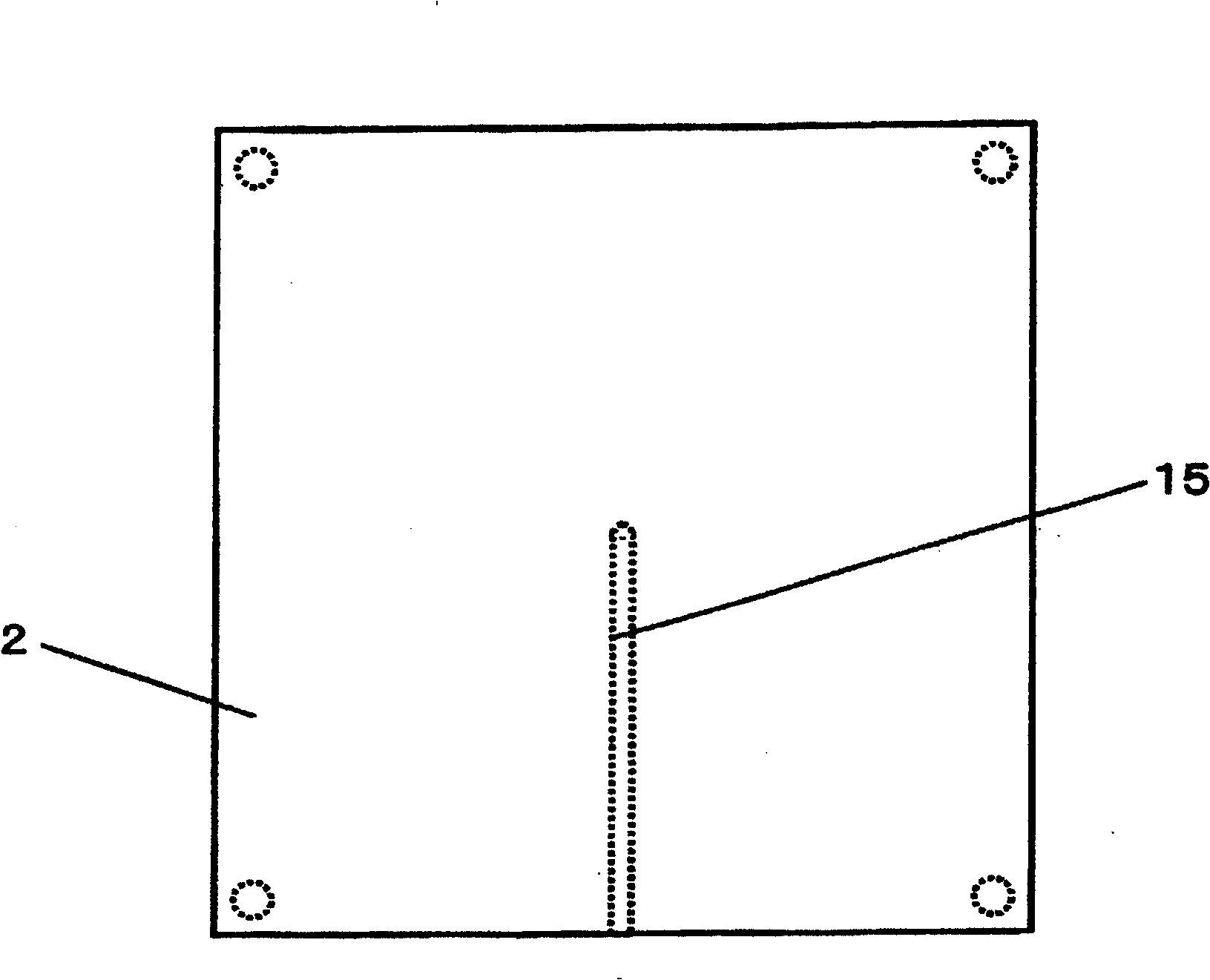

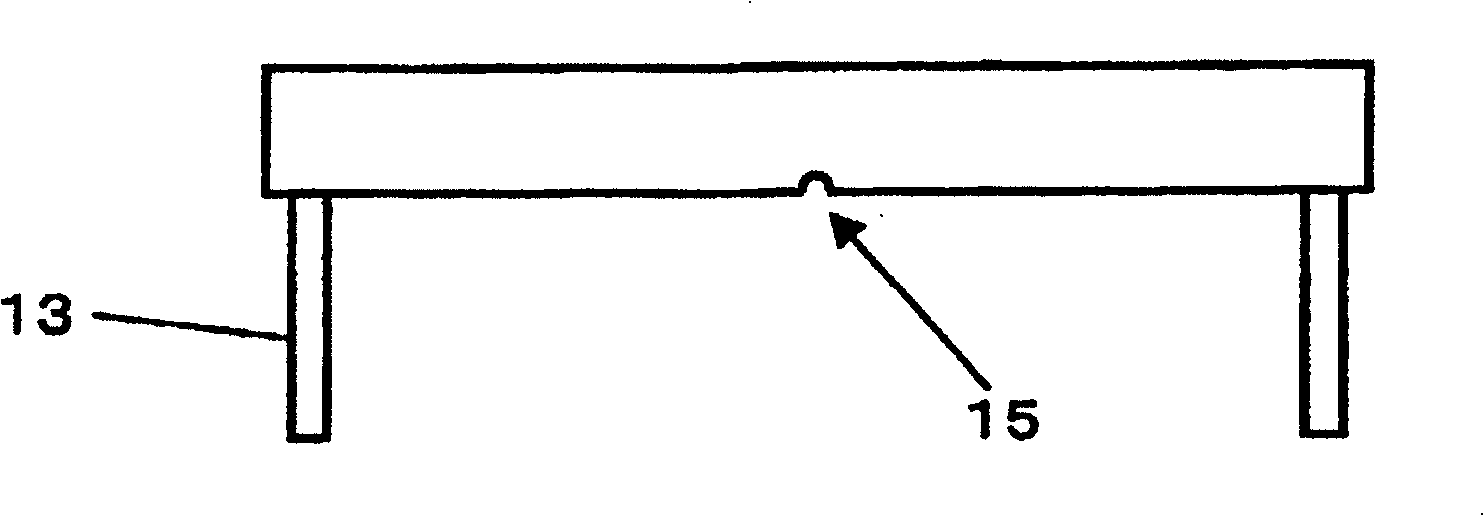

[0219] In the RTM molding system 54 according to this embodiment shown in FIG. 11 , an example of molding a large flat plate (length 1500 mm x width 700 mm x height (thickness) 3 mm) will be described as an example of molding according to the molding conditions of the present invention. The overall view of the RTM molding metal mold 1 used in this example is shown in Figures 8 and 9, and the relationship between the temperature and viscosity of the resin used in the molding and the resin curing degree-time characteristics at the molding temperature are shown in Figure 12A and Figure 12A. 12B. In the molding cavity 50 provided in the lower mold 43 of the molding mold 41 (the same as the upper mold 42 and the lower mold 43 with a length of 2000 mm, a width of 1000 mm, and a height of 350 mm) including the resin injection pipes 46 to 48 and the discharge pipe 49 , laminated 8 layers (0 / 90° oriented substrate, 4 layers; ±45° oriented substrate, 4 layers) Toray Co., Ltd. carbon fib...

Embodiment 3

[0235] In addition, the above-mentioned Example 2 is a single-plate structure of reinforced fiber resin base material, as another example, even if it is a carbon-reinforced fiber sandwich structure with a core (thickness 10 mm, surface specific gravity 0.1) inside By laminating three layers of the above-mentioned carbon fiber "torayca" fabric on the upper and lower surfaces respectively), molded products with almost the same surface quality can be obtained. Incidentally, the impregnation time is about 4.5 minutes, which is the same short time as above.

[0236] Next, the RTM molding method according to the third embodiment of the present invention will be described. First, production of a reinforcing fiber base material according to this RTM molding method will be described with reference to FIG. 18 . As shown in FIG. 18, a resin injection port 85 and a suction port 86 are provided in an upper die 83 of the two dies. The lower mold 84 includes a resin injection flow path 88 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com