Extraction device applied to conjoined cylinder sleeve

A cylinder liner and conjoined technology, which is applied to equipment, manufacturing tools, and metal processing equipment for feeding molten metal into molds, etc., can solve problems such as poor adaptability of extraction devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

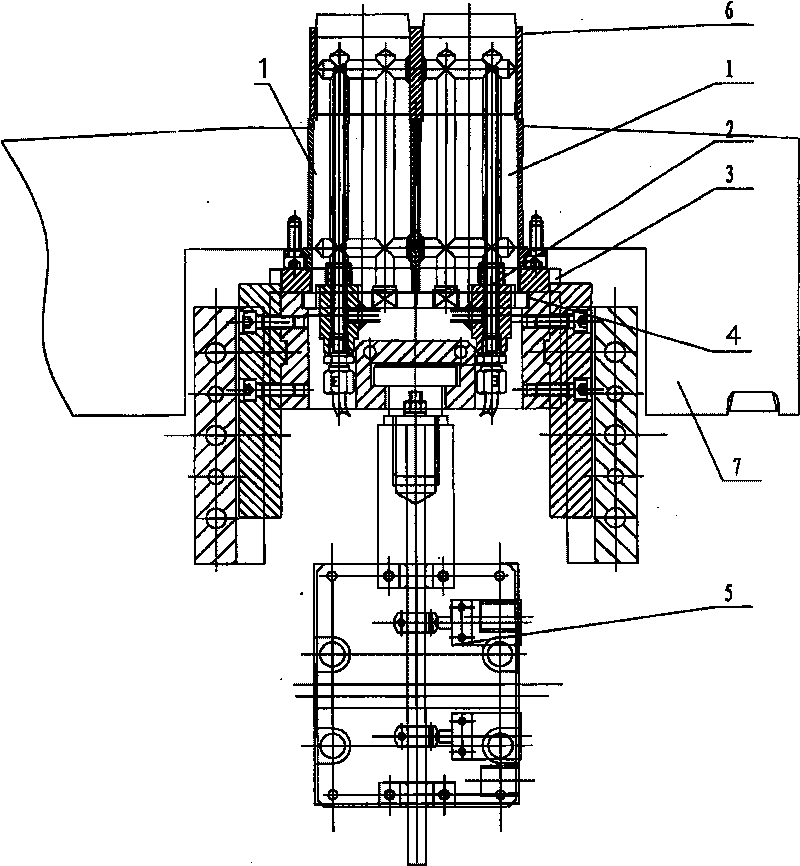

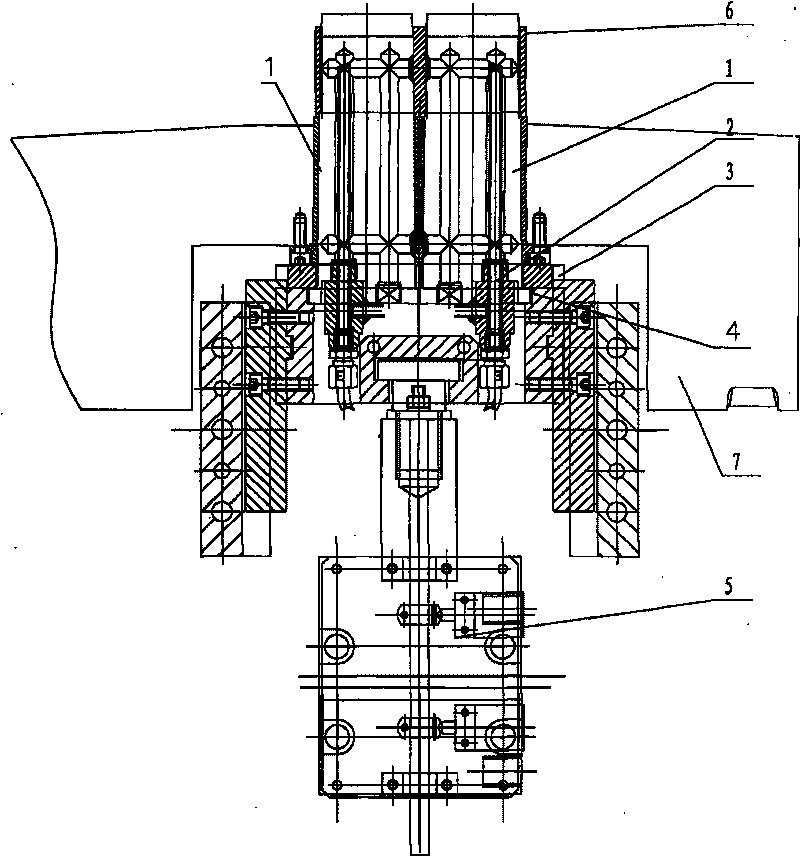

[0008] The specific structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

[0009] See attached figure 1 As shown, an extracting device applied to a one-piece cylinder liner includes an oil cylinder driving device 5, a core pulling seat 3 driven by the driving device 5 to slide up and down, a core pulling seat cover plate 2, a core pulling seat 3 and a core pulling seat installed on the core pulling seat 3. There are two cylinder liner rods 1 on the seat cover plate 2, which are arranged side by side and adjacent to each other, and are used in conjunction with the one-piece cylinder liner 6. The cylinder liner rods 1 are movably installed on the core-pulling seat 3 and the core-pulling There is a gap 4 between the cylinder liner rod 1 and the core pulling seat 3 and the core pulling seat cover plate 2 .

[0010] The cylinder driving device 5 drives the two cylinder liner rods 1 to slide up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com