Self-assembling electrode with resveratrol molecular imprinting and method for making same

A technology of resveratrol and molecular imprinting, which is applied in the direction of measuring devices, analytical materials, and electrochemical variables of materials, can solve the problem of poor stability and reproducibility, and there is no literature report on resveratrol molecular imprinting electrochemistry. Preparation and application of chemical sensors to achieve high sensitivity, simple operation, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

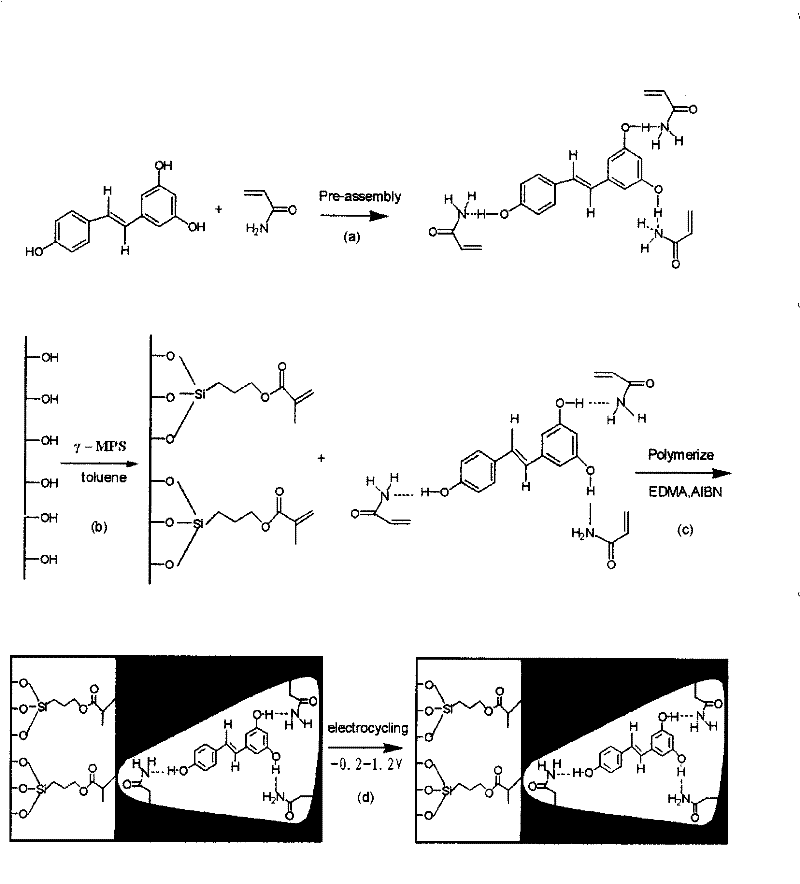

Method used

Image

Examples

example 1

[0051] 1. Put the ITO glass electrode in acetone for 15 minutes and then put it into a mixed solution of NaOH (1M) and ethanol (volume ratio 1:1) for 15 minutes. Then wash with acetone, ethanol and double distilled water respectively. Sonicate the washed ITO glass in KOH solution for 15min. Then put it into a toluene solution of γ-(methacryloyloxy)propyltrimethoxysilane with a mass fraction of 0.14%, take it out after silanization in a water bath at 60° C. for 24 hours, rinse it with methanol three times, and dry it with nitrogen.

[0052] 2. Weigh 0.038g (0.17mmol) resveratrol and dissolve it in 2mL acetonitrile, add 0.071g (1mmol) functional monomer acrylamide, 0.673g (3.4mmol) cross-linking agent EDMA and 0.01g (0.06mmol) Initiator AIBN is fully mixed, nitrogen gas is passed for 5 minutes, and then ultrasonic degassing is performed for 10 minutes. Then put the above-mentioned silanized ITO glass electrode into the mixed solution, seal the container, put it into a vacuum d...

example 2

[0056] 1. Put the ITO glass electrode in acetone for 15 minutes and then put it into a mixed solution of NaOH (1M) and ethanol (volume ratio 1:1) for 15 minutes. Then wash with acetone, ethanol and double distilled water respectively. Sonicate the washed ITO glass in KOH solution for 15min. Then put it into a toluene solution of γ-(methacryloyloxy)propyltrimethoxysilane with a mass fraction of 0.14%, take it out after silanization in a water bath at 60° C. for 24 hours, rinse it with methanol three times, and dry it with nitrogen.

[0057] 2. Weigh 0.038g (0.17mmol) resveratrol and dissolve it in 2mL acetonitrile, add 0.071g (1mmol) functional monomer acrylamide, 0.914g (2.27mmol) cross-linking agent TRIM and 0.01g (0.06mmol) Initiator AIBN is fully mixed, nitrogen gas is passed for 5 minutes, and then ultrasonic degassing is performed for 10 minutes. Then put the above-mentioned silanized ITO glass electrode into the mixed solution, seal the container, put it into a vacuum ...

example 3

[0061] 1. Put the ITO glass electrode in acetone and sonicate for 15 minutes, then put it into a mixed solution of NaOH (1M) and ethanol (1:1 by volume) and sonicate for 15 minutes. Then wash with acetone, ethanol and double distilled water respectively. Sonicate the washed ITO glass in KOH solution for 15min. Then put it into a toluene solution of γ-(methacryloyloxy)propyltrimethoxysilane with a mass fraction of 0.14%, take it out after silanization in a water bath at 60° C. for 24 hours, rinse it with methanol three times, and dry it with nitrogen.

[0062] 2. Weigh 0.038g (0.17mmol) resveratrol and dissolve it in 2mL acetonitrile, add 0.056g (1mmol) functional monomer acrylic acid, 0.673g (3.4mmol) cross-linking agent AIBN and 0.01g (0.06mmol) initiating The agent AIBN was thoroughly mixed, passed nitrogen for 5 minutes, and then ultrasonic degassed for 10 minutes. Then put the above-mentioned silanized ITO glass electrode into the mixed solution, seal the container, put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com