Device for preventing mounting vehicle parts by mistake

A technology for auto parts and error prevention, which is applied in the field of anti-misinstallation devices for auto parts, can solve problems such as economic losses, no error-proof installation, and different steel plate materials, and achieve the effects of saving production costs, ensuring automobile quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

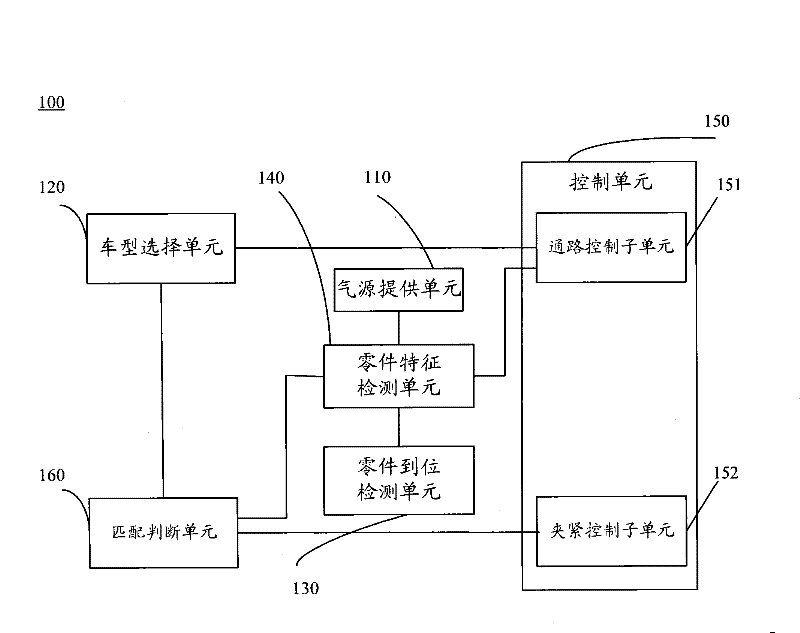

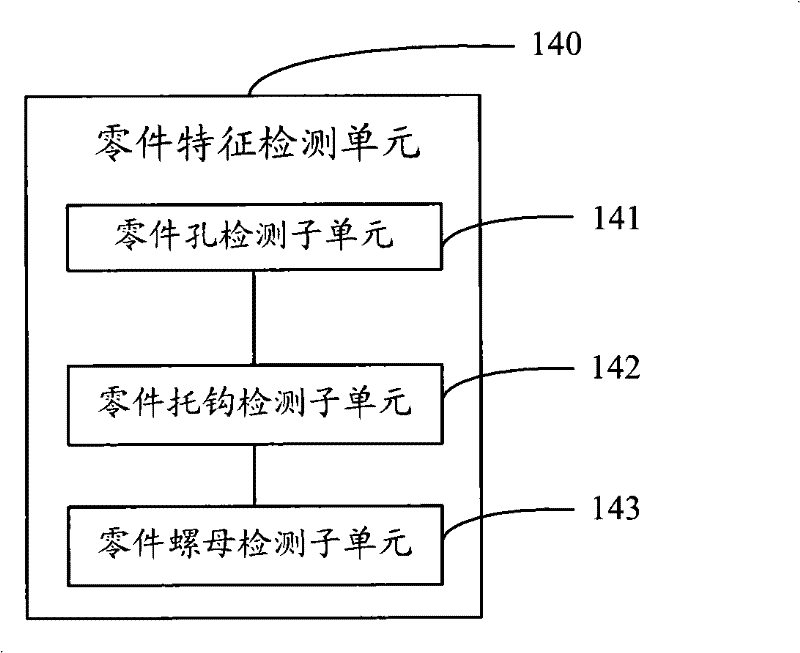

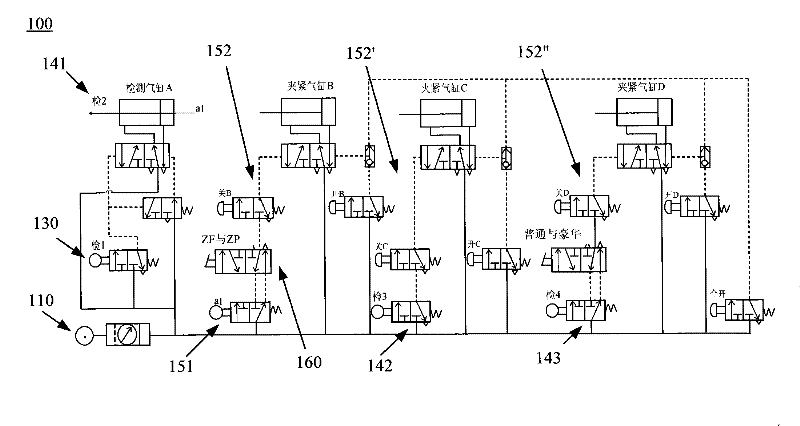

[0034] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides an anti-misinstallation device for automobile parts, which includes a model selection unit, a part feature detection unit, a control unit and an air source supply unit. The vehicle type selection unit is used to select a vehicle type. The part feature detection unit is used to detect the feature of the part that reaches the specified position. The control unit is used for controlling the clamp to clamp the part when the feature detected by the part feature detection unit matches the vehicle type selected by the vehicle type selection unit. The air source supply unit is used to provide an air source to the component detection unit. The anti-misinstallation device for auto parts of the present invention detects the characteristics of the parts that have reached the designat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com