Pneumatic tire tread with sipes and mold blade

A tire tread, tread technology, applied in tire parts, tire tread/tread pattern, tire, etc., can solve problems such as rubber peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] What is described below is what is presently believed to be the best mode of carrying out the invention. The description given here is intended to illustrate the general principles of the invention and should not be taken as limiting, the scope of the invention being best determined by reference to the appended claims.

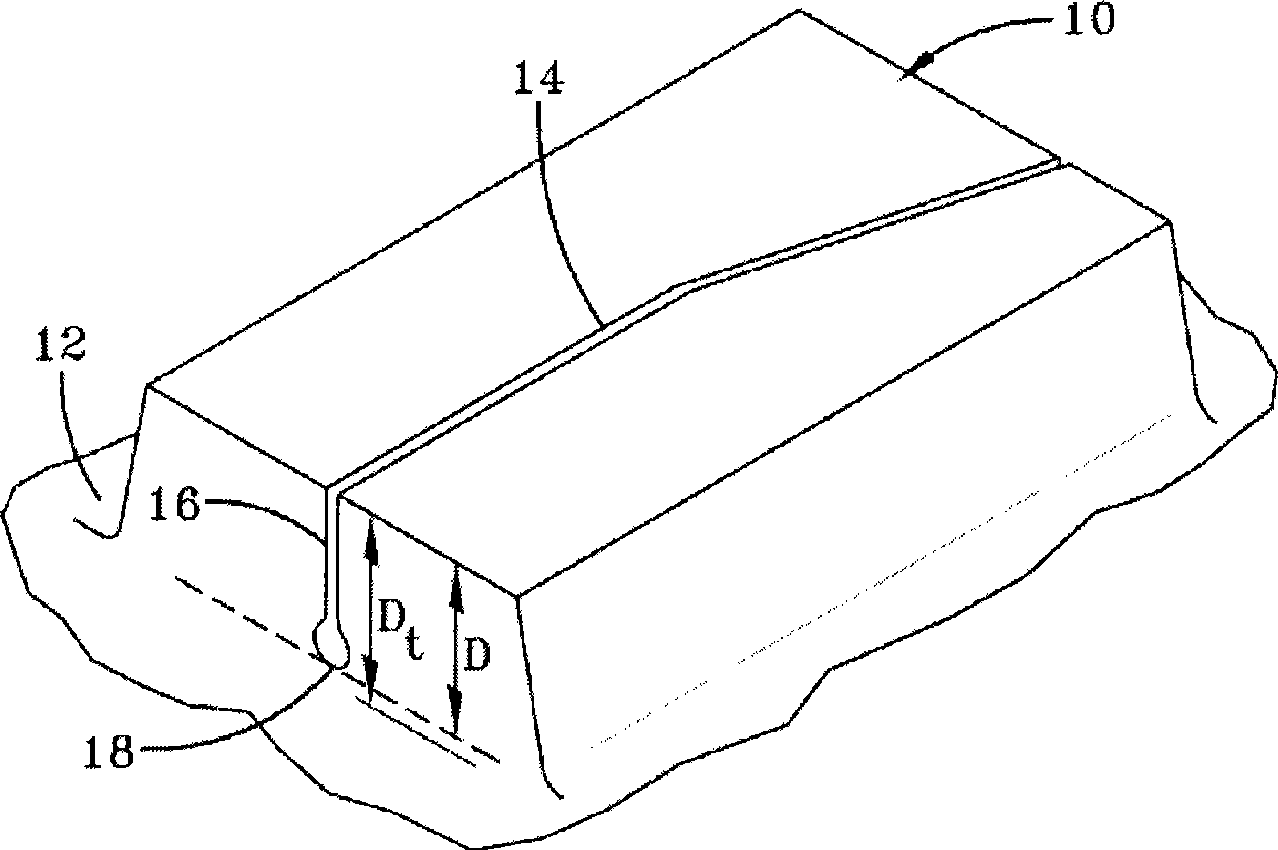

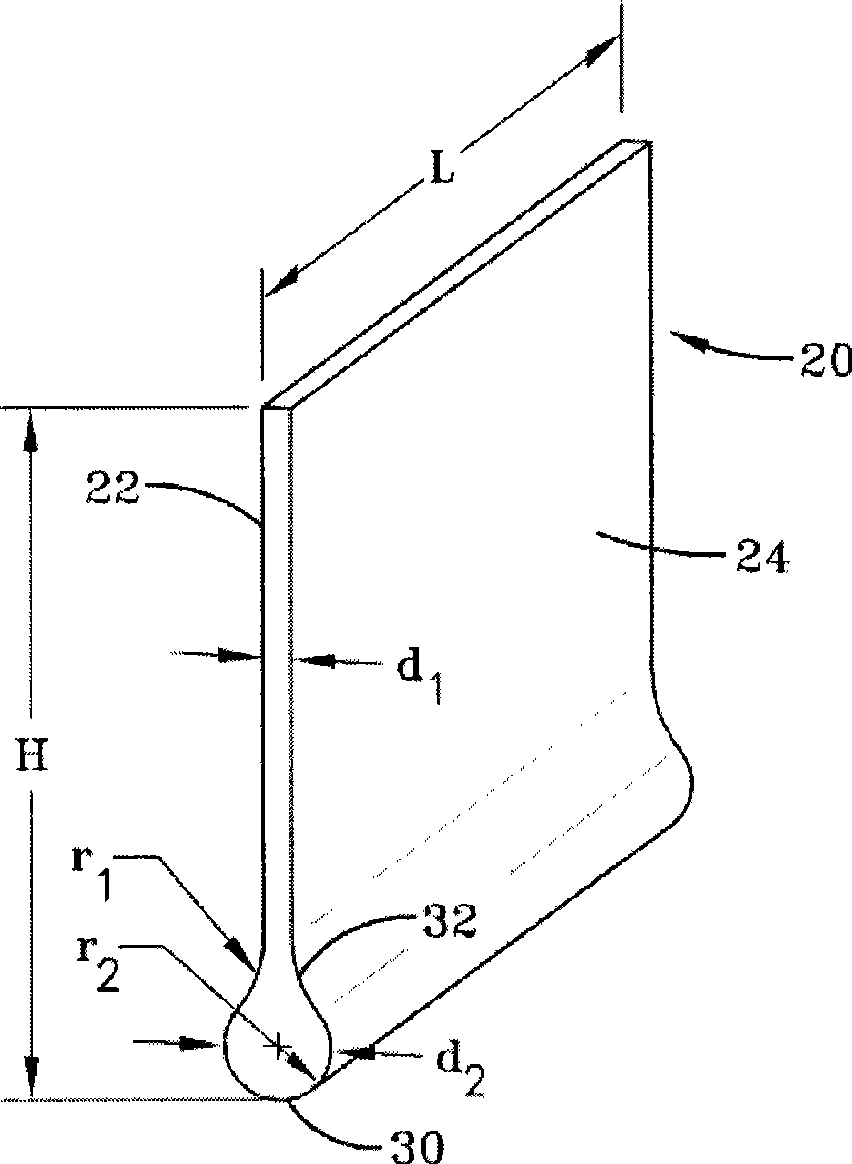

[0025] figure 1 is a tread element 10 for a pneumatic tire tread. As is well known to those skilled in the art, this tread element 10 is formed by at least one groove 12, either peripherally or laterally. If the tread element 10 were defined only by peripherally extending grooves, the tread element would be a tread rib. A tread element 10 is considered to be a tread block if it is formed by grooves on at least three sides. Tread elements 10 may be located anywhere on the tread, namely along the tread shoulders, along the centerline or some intermediate position. The depth of the grooves 12 forming the tread elements determines the antiskid depth Dt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com