Ultrafast sintering method for preparing carbon nano-tube reinforced ceramic

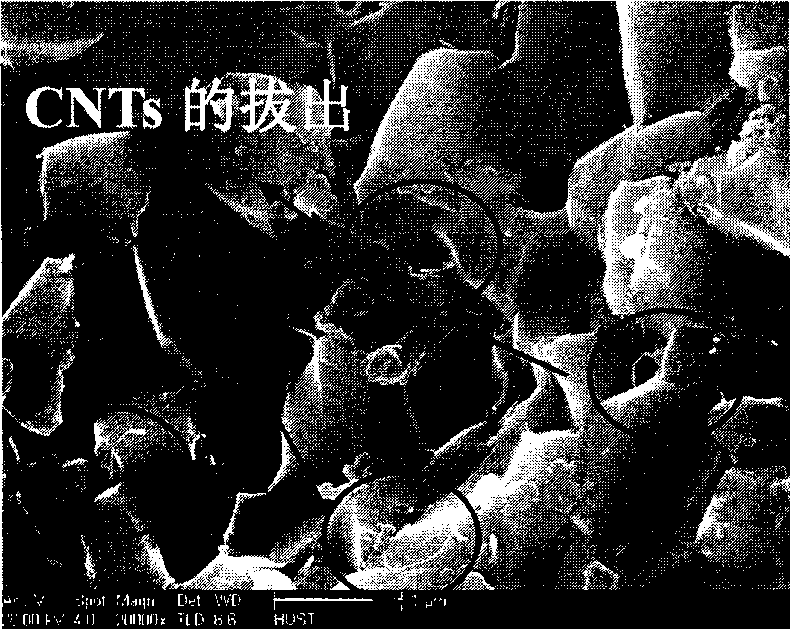

A technology of carbon nanotubes and sintering method is applied in the field of preparation of carbon nanotube reinforced ceramics, which can solve the problems of slow heating rate, short duration of high temperature, damage and the like, and achieve the effects of avoiding damage and improving fracture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

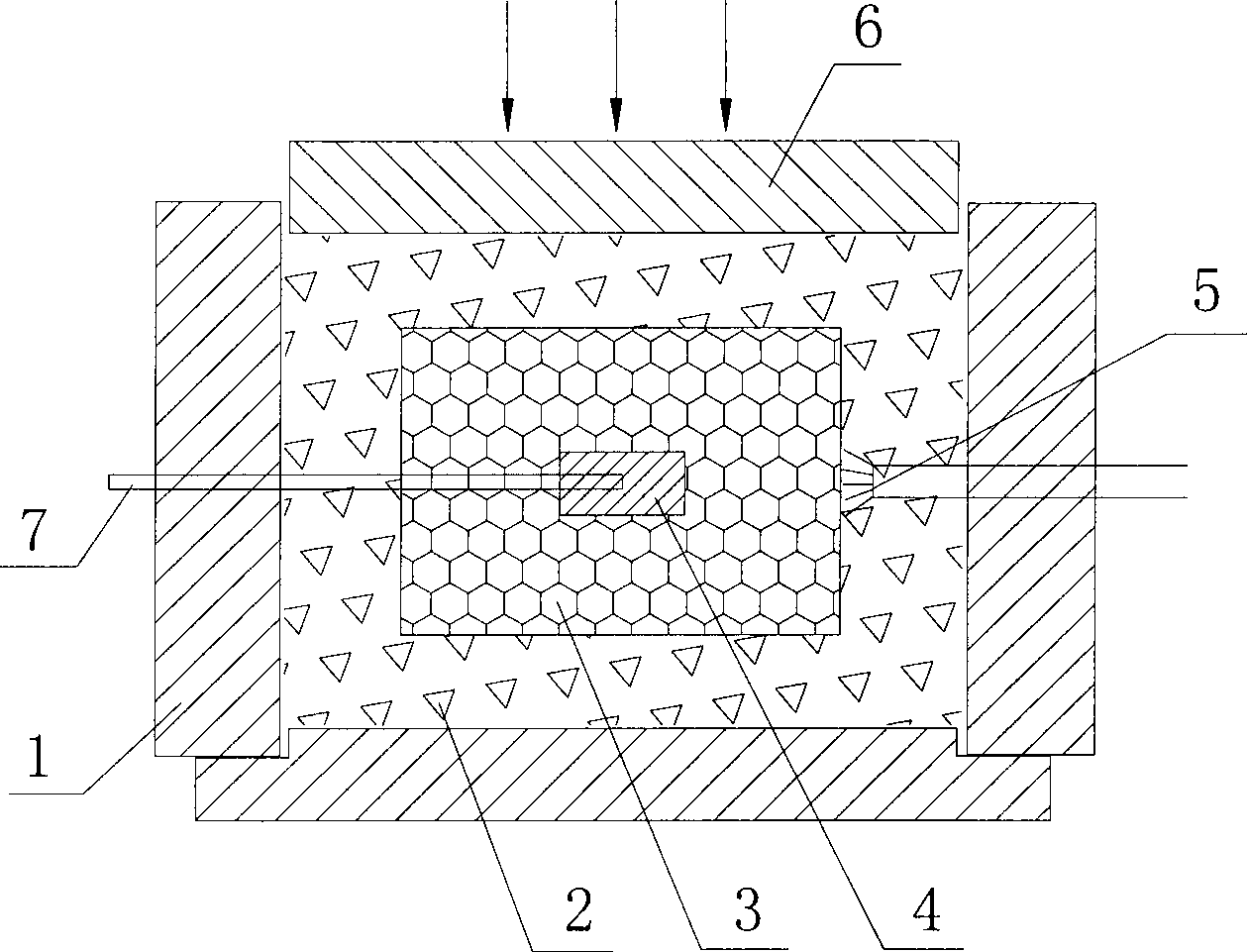

[0028] Such as figure 1 Shown, a kind of ultrafast sintering method of preparing carbon nanotube reinforced ceramics, it comprises the steps:

[0029] 1) According to the mass of carbon nanotube (CNTs) powder as Al 2 o 3 0.5wt% of powder mass, Al 2 o 3 Powder is 3g, choose carbon nanotube powder and Al 2 o 3 powder; disperse carbon nanotube (CNTs) powder and alumina powder (200nm) in alcohol, and ultrasonically disperse for 2h to obtain slurry; wherein the quality of alcohol is Al 2 o 3 3 times the mass of the powder;

[0030] 2) Ball mill the obtained slurry for 24 hours (the ball milling medium is agate balls), and remove the alcohol by rotary evaporation to obtain a dry and evenly mixed composite powder;

[0031] 3) Pressing the obtained composite powder into a disc shape (20mm in diameter and 3mm in thickness) to obtain the blank of the material to be sintered;

[0032] 4) Select Cr 2 o 3 +Al+C system is a solid combustion reaction material, Cr 2 o 3 : The rat...

Embodiment 2

[0037] An ultrafast sintering method for preparing carbon nanotube reinforced ceramics, comprising the steps of:

[0038] 1) According to the mass of carbon nanotube (CNTs) powder as TiB 2 1wt% of powder mass, TiB 2 The powder is 3g, choose carbon nanotube powder and TiB 2 powder; carbon nanotube powder and TiB 2 The powder is dispersed in alcohol, ultrasonically dispersed for 2 hours to obtain a slurry; the mass of alcohol is TiB 2 5 times the mass of the powder;

[0039] 2) Ball mill the obtained slurry for 24 hours (the ball milling medium is agate balls), and remove the alcohol by rotary evaporation to obtain a dry and evenly mixed composite powder;

[0040] 3) Pressing the obtained composite powder into a disc shape (20mm in diameter and 3mm in thickness) to obtain the blank of the material to be sintered;

[0041] 4) Select the Ti+C system as the solid combustion reaction material, the ratio of the amount of Ti:C is 1:1, the highest combustion temperature is 2620 ° ...

Embodiment 3

[0046] An ultrafast sintering method for preparing carbon nanotube reinforced ceramics, comprising the steps of:

[0047] 1) According to the mass of carbon nanotube (CNTs) powder as Al 2 o 3 0.5wt% of powder (200nm) mass, Al 2 o 3 Powder is 3g, choose carbon nanotube powder and Al 2 o 3 powder; carbon nanotube powder and Al 2 o 3 Disperse the powder in alcohol and ultrasonically disperse for 2 hours to obtain a slurry; the mass of the alcohol is 6 times the mass of the ceramic powder;

[0048] 2) Ball mill the obtained slurry for 24 hours (the ball milling medium is agate balls), and remove the alcohol by rotary evaporation to obtain a dry and evenly mixed composite powder;

[0049] 3) Pressing the obtained composite powder into a disc shape (20mm in diameter and 3mm in thickness) to obtain the blank of the material to be sintered;

[0050] 4) Choose Ti+C+ diluent as the solid combustion reaction material, the ratio of the amount of Ti:C is 1:1, the diluent is TiC, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com