Belt feeder

A feeder and chain belt technology, applied in the field of continuous feeding devices, can solve the problems that the bottom plate cannot withstand the warehouse pressure, the feeding is discontinuous, and the adjustment of the feeding amount is difficult, so as to prevent dust from flying, reduce pollution, and reduce vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

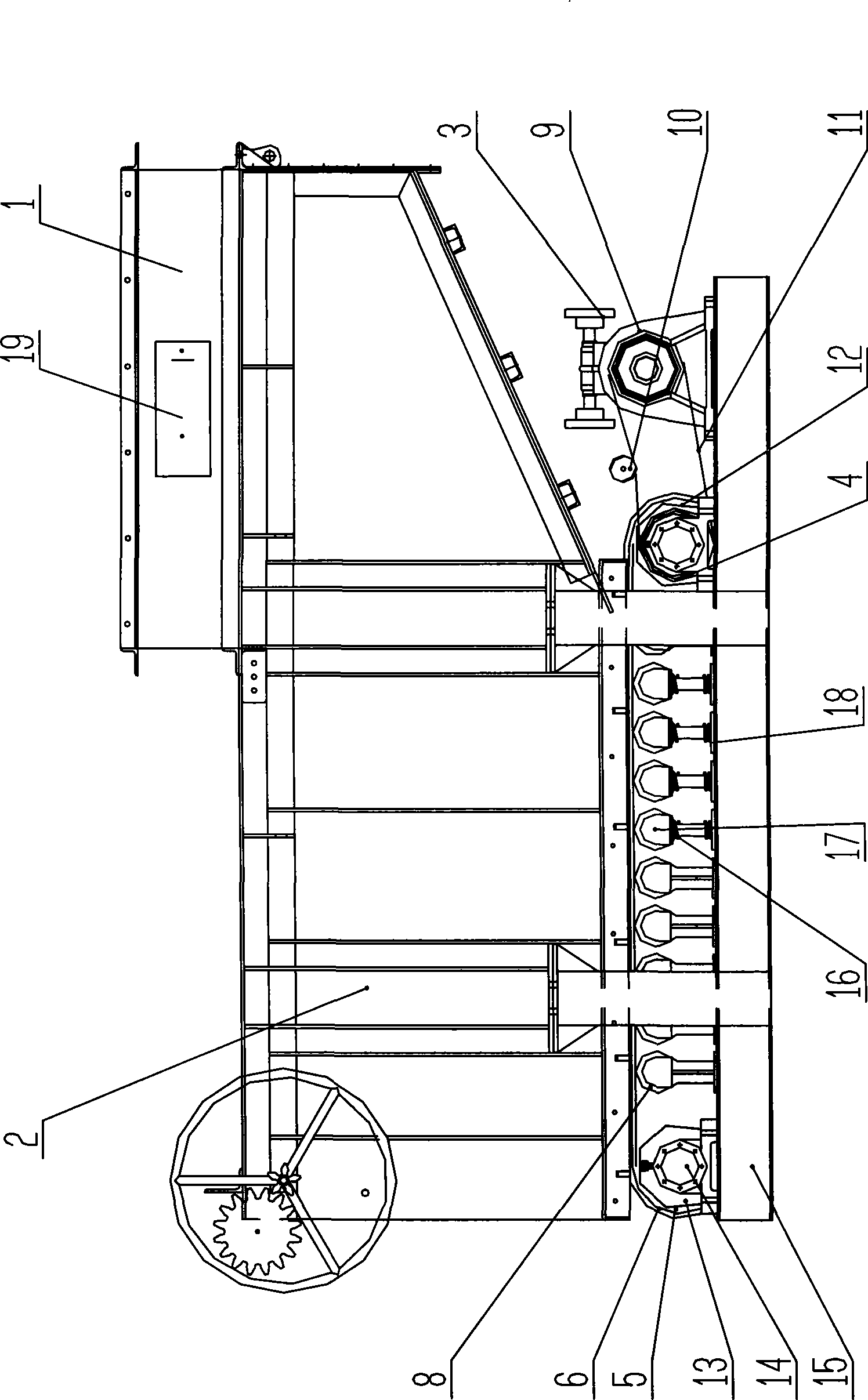

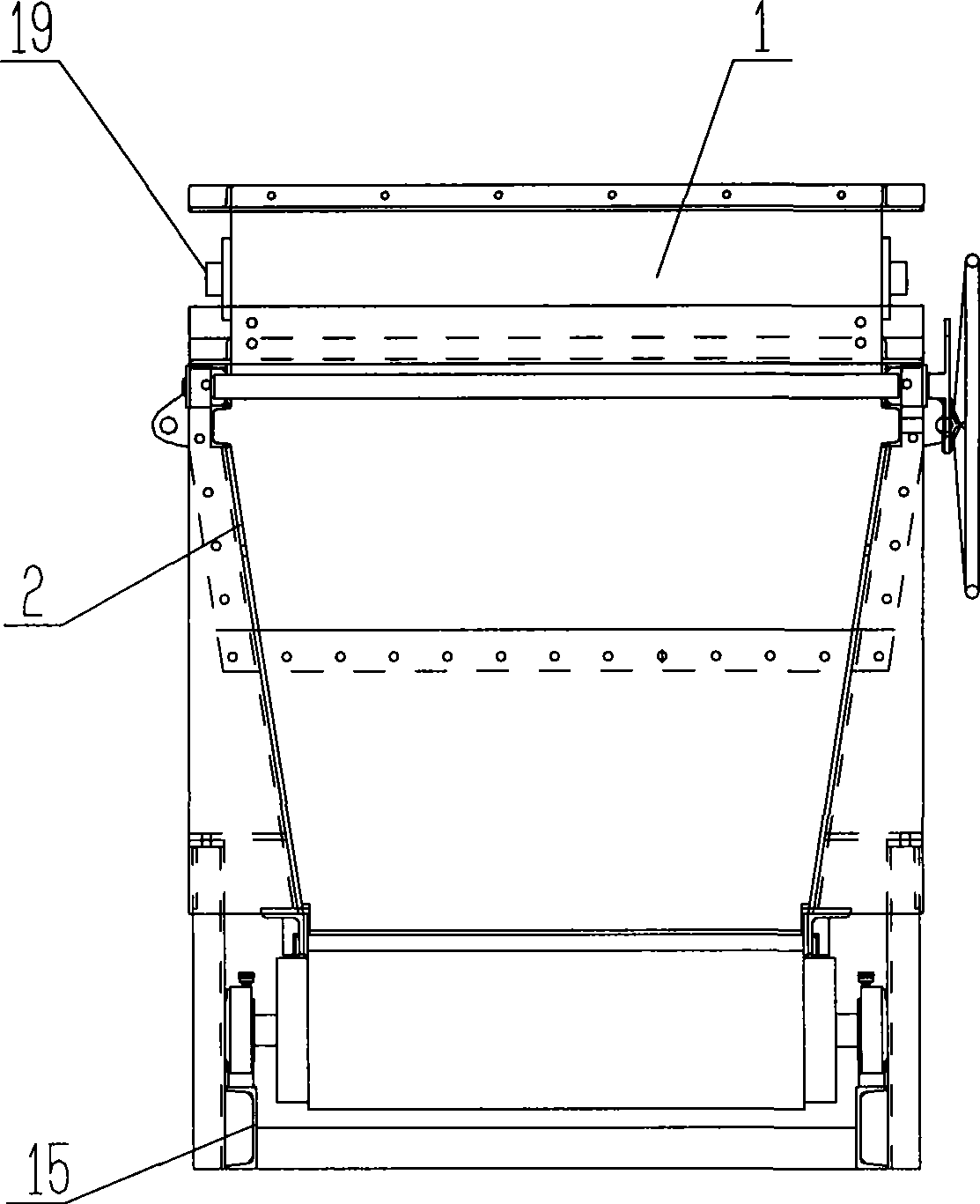

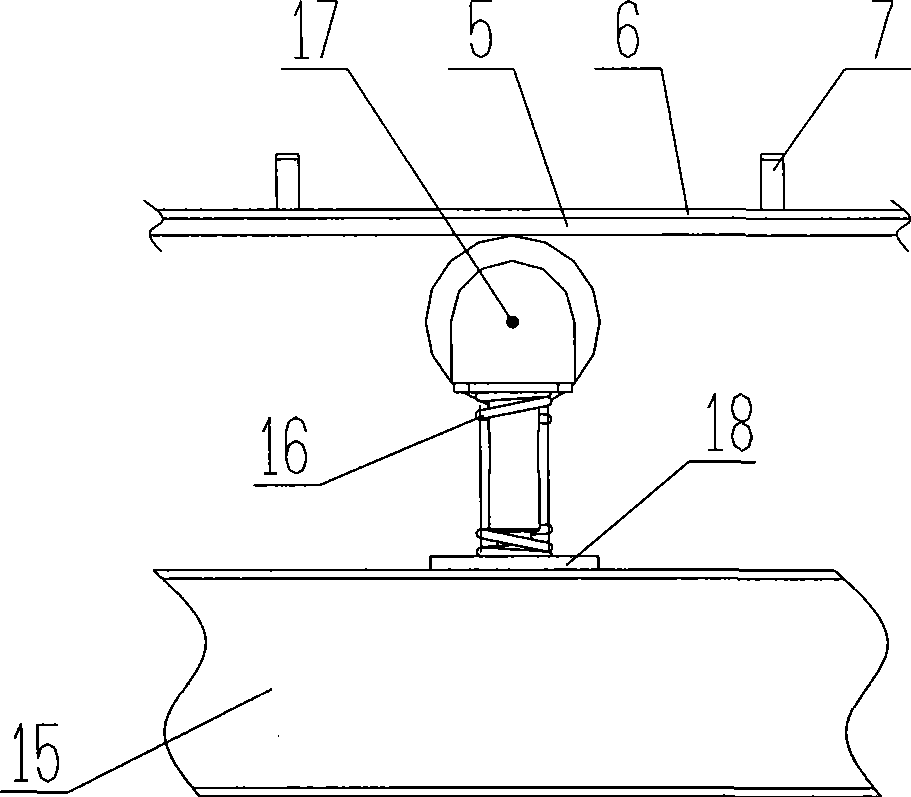

[0022] Such as Figure 1 to 2 As shown, in the belt feeder of the present invention, the feeding trough 1, the box body 2, the driving device 3 are installed on the base 15, and the driving drum 4 and the redirecting drum 13 are respectively installed on the base 15 through the bearing seat 14. , The bearing seat 14 is provided with an oil filling hole 20, which can be used to add oil and lubricate under the condition of continuous operation of the feeder. The support and the small drum 8 are installed on the base through the shock-absorbing support 17 and the shock-absorbing support bottom plate 18. 15. A chain belt consisting of a rubber-faced whole-core flame-retardant conveyor belt 5 and an armor belt 6. A raised plate 7 is evenly distributed on the armor belt 6, which can hang the material; the chain on the drive device 3. Wheel one 9 drives the sprocket two 12 on the drive drum 4 to rotate through the chain 11. A tension wheel 10 is installed on the chain 11 to adjust the tig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap