Composite organic insulation construction with variable dielectric coefficient-resistance and preparation thereof

A dielectric constant and organic insulation technology, which is applied in the field of composite material insulation structure and its preparation, can solve the problems of poor reliability and unstable material performance, and achieve the effect of improving vacuum withstand voltage performance and surface flashover voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

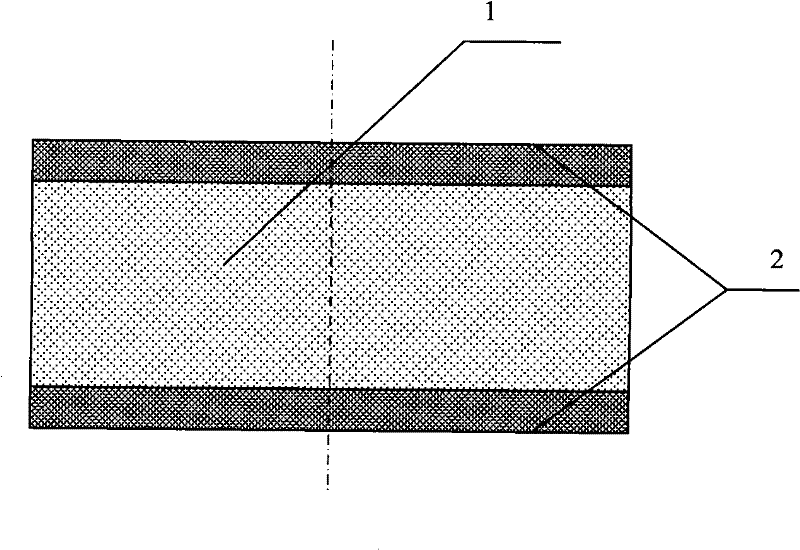

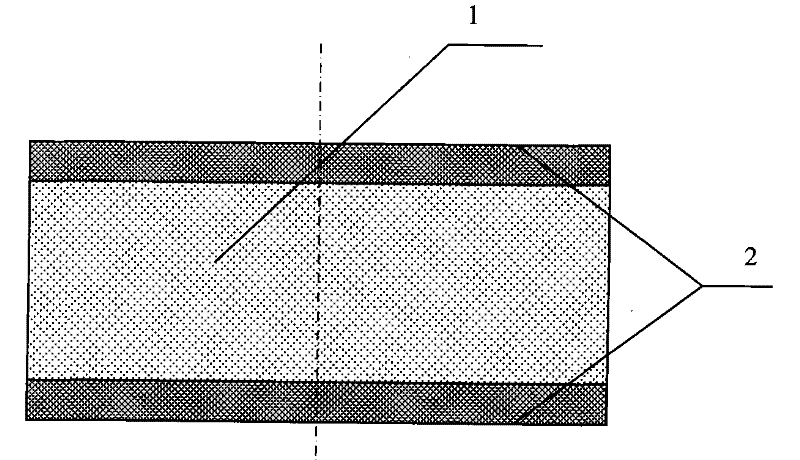

[0020] figure 1 The preparation method of the composite organic insulating structure with variable dielectric constant-resistivity includes the following steps:

[0021] 1) The polyethylene matrix 1 is prepared by conventional organic material technology, and its two ends are smoothed;

[0022] 2) Preparation of composite material wafer 2: according to mass percentage, take 1-90% of semi-conductive material and 10-99% of polyethylene for weighing. The semi-conductive material is a compound material of polyethylene and carbon black specially used for cables. The commercially available semi-conductive material is pyjbj-083, and each composition is mixed in an open rubber mixer for 20-30 Minutes, then cut into small pieces, preheat at 150°C for 10 minutes after filling the mold, keep the temperature and press in a flat vulcanizer for 3 to 5 minutes, the hot pressing pressure is 10Mpa, and finally make a 1mm thick compound After the plate is punched into a disc, the two ends ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com