Stirring inner water cooling isothermal quench salt bath

A technology of isothermal quenching and salt bath, applied in the direction of quenching agent, quenching device, heat treatment equipment, etc., can solve the problems of high energy consumption, complex structure, poor effect, etc., achieve low energy consumption, reduce temperature fluctuation, and good quenching effect Effect

Inactive Publication Date: 2011-01-05

WUHAN TEXTILE UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the problems of complex structure, high energy consumption or poor effect in the current isothermal quenching salt bath device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

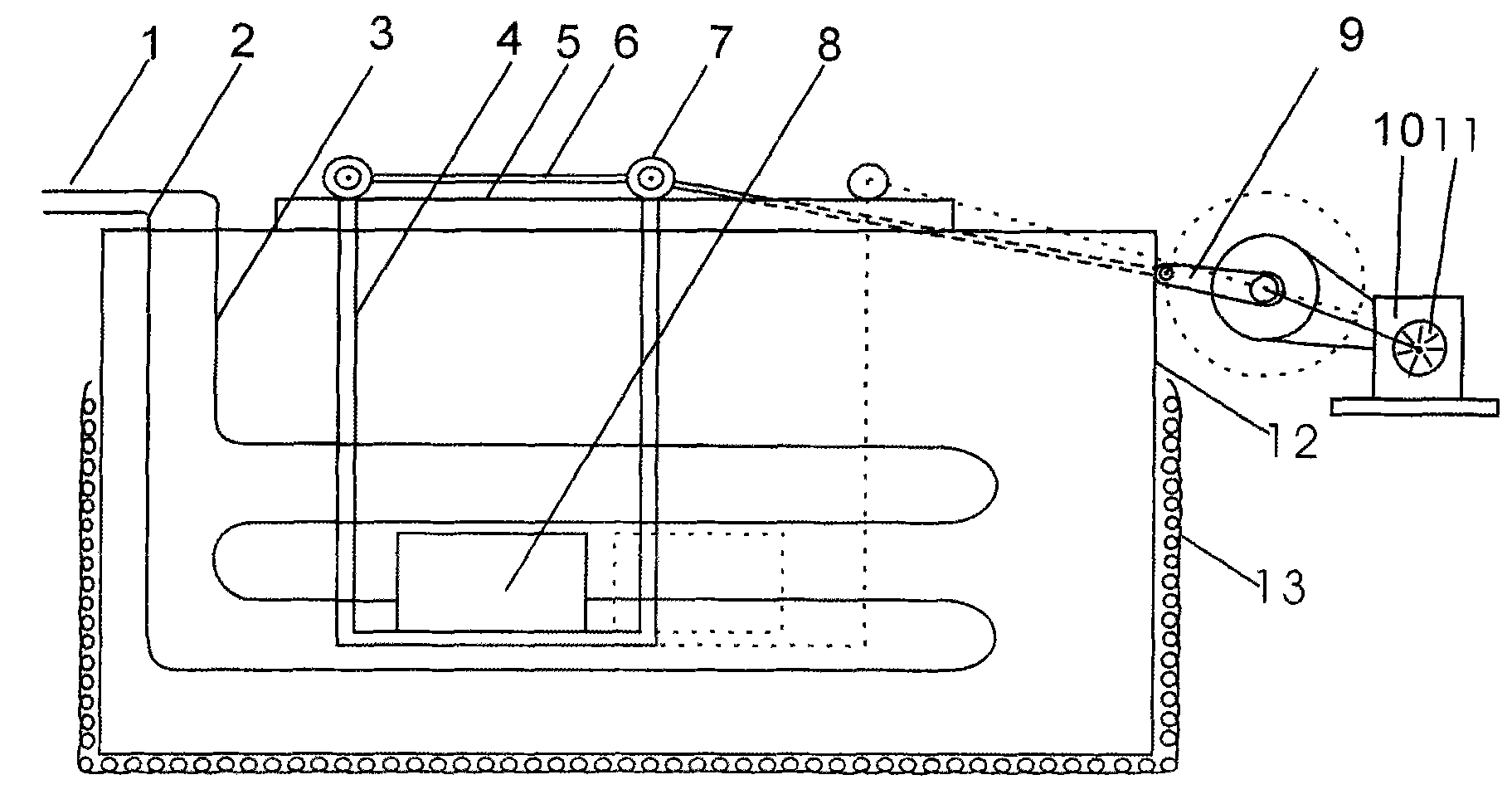

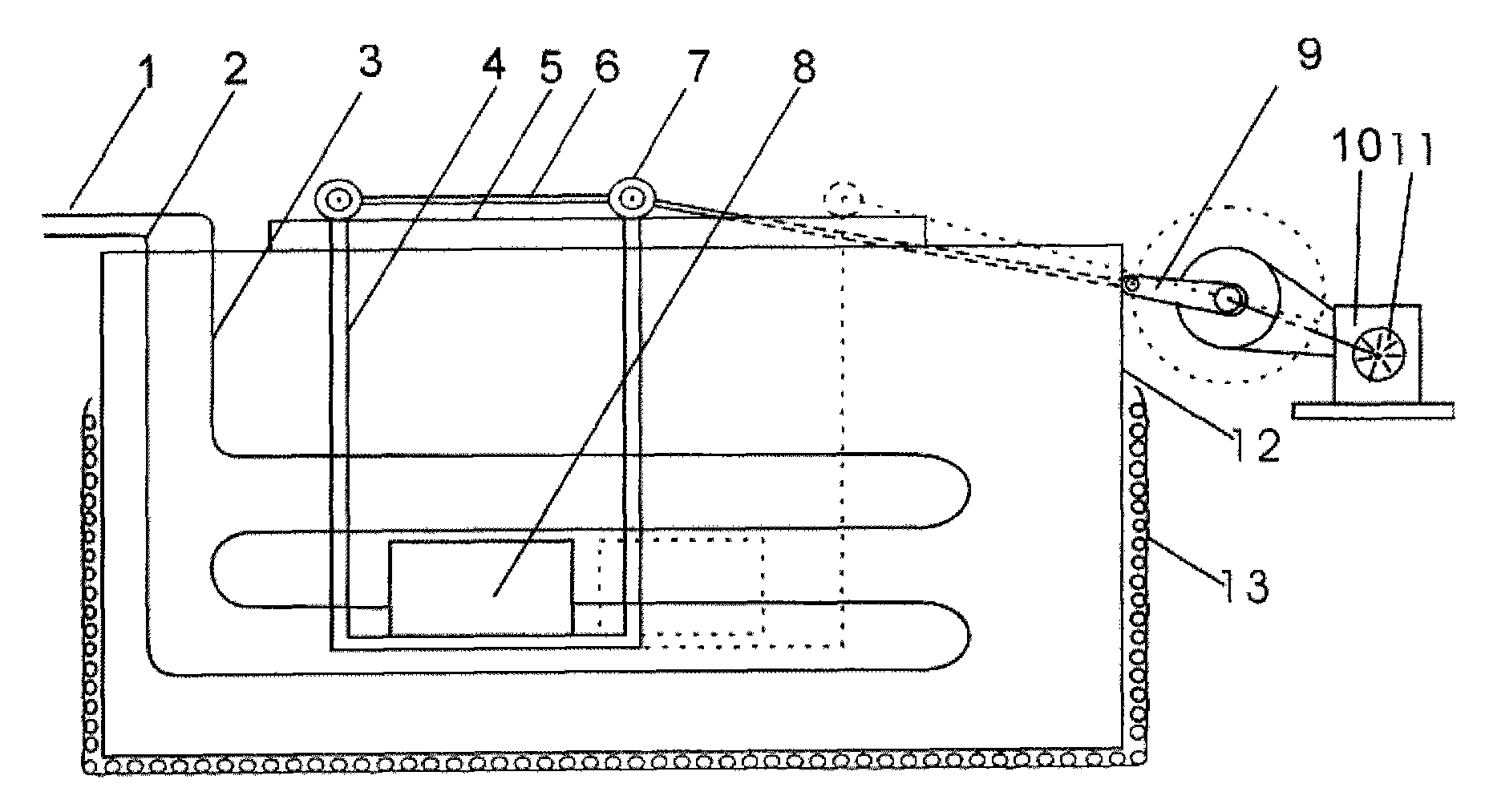

Abstract

The invention discloses a stirring inner water cooling austempering salt bath. The two sides above the salt bath are provided with orbits and a movable rack with rolling wheels which are arranged in the orbits, a work rest in the bath body is fixedly connected with the movable rack, and a work rest bearing the work pieces or work piece hurdles moves back and forth driven by a swinging mechanism through the movable rack to stir the salt bath, thus leading to the rapid heat dissipation and cooling of high temperature austenitizing work pieces and uniform temperature of the salt bath; and the inner walls on the two sides near the bath are provided with snake-shaped cooling pipes by which the bath is communicated with a cooling pool, and then circulating cooling water is pumped in the bath tostrengthen the function of heat dissipation and cooling of the salt bath and cause the bath to rapidly return to the set austempering temperature. The churning inner water cooling austempering salt bath has the advantages of simple structure, convenient operation, less energy losses and stable salt bath temperature and the salt bath is applicable to small serial production and mass mechanized production. The salt bath can harden ADI pieces with the thickness being 80mm, thus avoiding the problems of not hardening matrix and residual ferrite (pearlite), so the salt bath is suitable for producing high-quality products.

Description

A stirrable internal water-cooled isothermal quenching salt bath technical field The invention relates to a stirrable internal water-cooled isothermal quenching salt bath for heat treatment of austempering ductile iron (ADI), belonging to the technical field of austempering ductile iron heat treatment. Background technique Austempered Ductile Iron (ADI) is a casting engineering material emerging in the past 30 years with high strength, high wear resistance and certain toughness, and it is being continuously promoted and applied at home and abroad. The manufacturing process is: cast ductile iron rough casting (spherical graphite + pearlite and ferrite matrix) → complete austenitization heating (spherical graphite + austenite) → austempering (spherical graphite + bainite or needle ferrite + high carbon stable retained austenite). That is to say, the ductile iron rough casting is heat-treated to retain the nodular graphite and change the matrix structure to obtain excellent ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D5/00C21D1/63C21D1/607C21D1/20

Inventor 龚文邦

Owner WUHAN TEXTILE UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com