Anneal oxidation method for punching slice in annealing oven

An annealing furnace and punching technology, which is applied in the annealing field of punching, can solve the problems that the magnetism of the punching sheet cannot achieve the ideal effect, the carbon content of the punching sheet is high, and the insulation of the oxide cannot achieve the ideal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

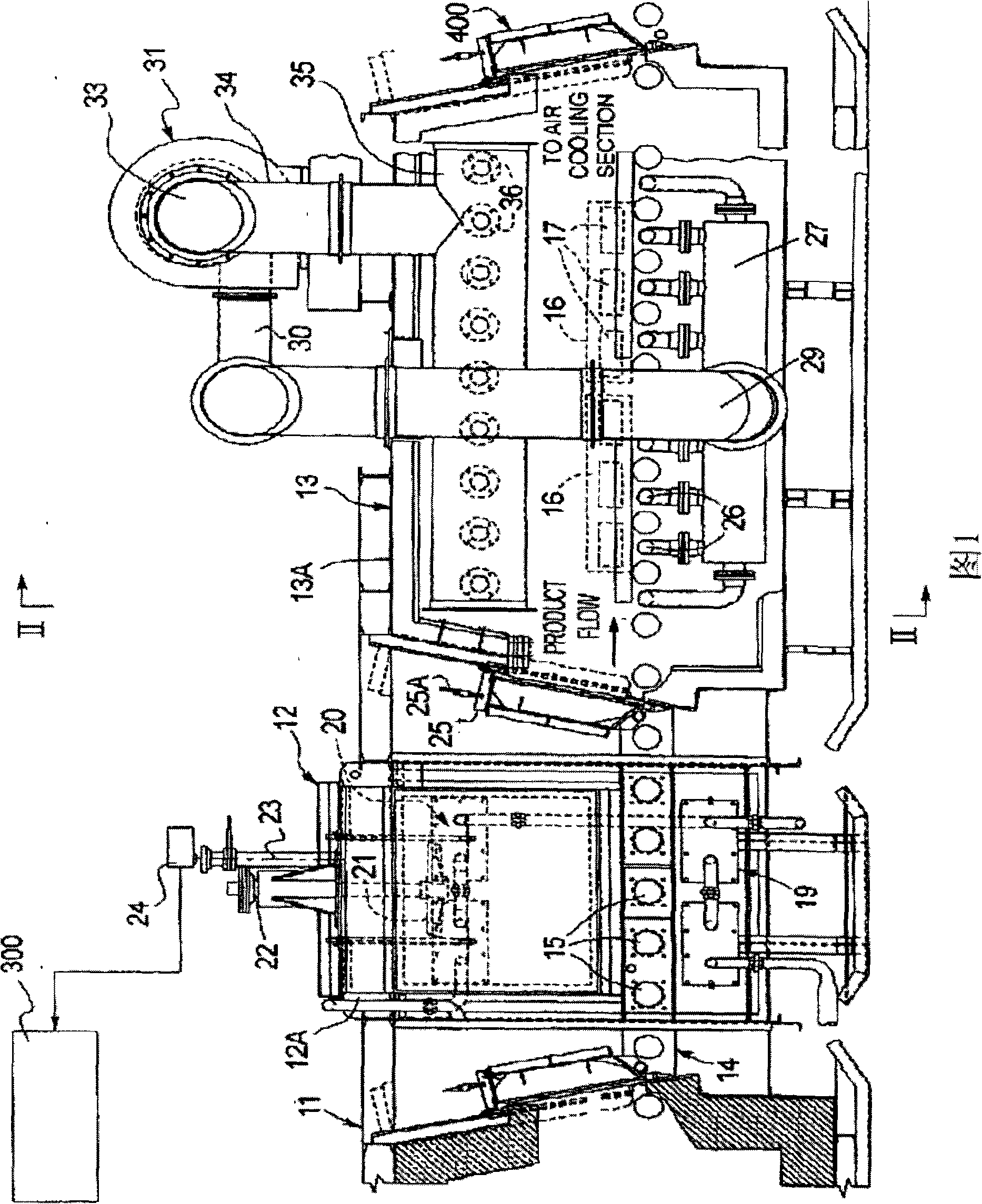

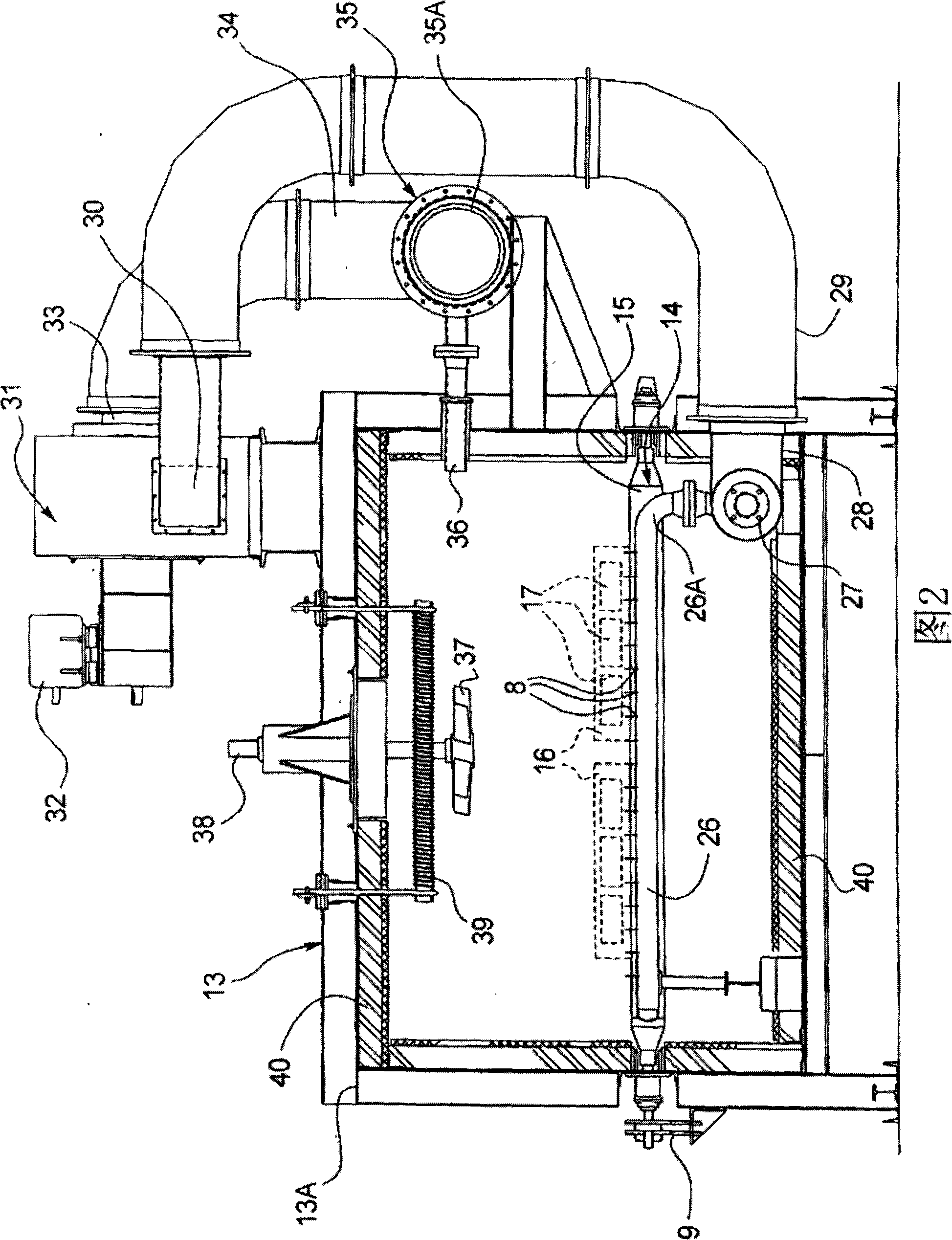

[0017] 1 and 2, what is shown in FIG. 1 is only a part of the annealing furnace. The annealing furnace in the figure includes a conveyor 14 with rollers to convey the tray 16 of the punching sheet 17, and the roller 15 of the conveyor 14 is driven by a gear 9. The conveying device 14 passes through the preheating zone of the annealing furnace, the high temperature zone (the preheating zone and the high temperature zone are not shown in the figure), the cooling zone 11, the purification zone 12, and the oxidation zone 13 in sequence. Anneal oxidation is carried out through the following steps:

[0018] The first is preheating and degreasing: the punched sheet is transported to a temperature of 400℃ for preheating, and the punched sheet is dried and degreasing.

[0019] The second is heating: the preheated and degreasing punch is transported to a high temperature zone for annealing at a temperature of 800°C, and nitrogen and hydrogen are introduced into the atmosphere of the high te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com