Reinforcement fiber cord excellent in adhesiveness and process for production of the same

An adhesion and fiber technology, applied in fiber processing, filament/thread forming, textile and papermaking, etc., can solve the problems of insufficient adhesion, expensive, non-adhesive, etc., and achieve excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

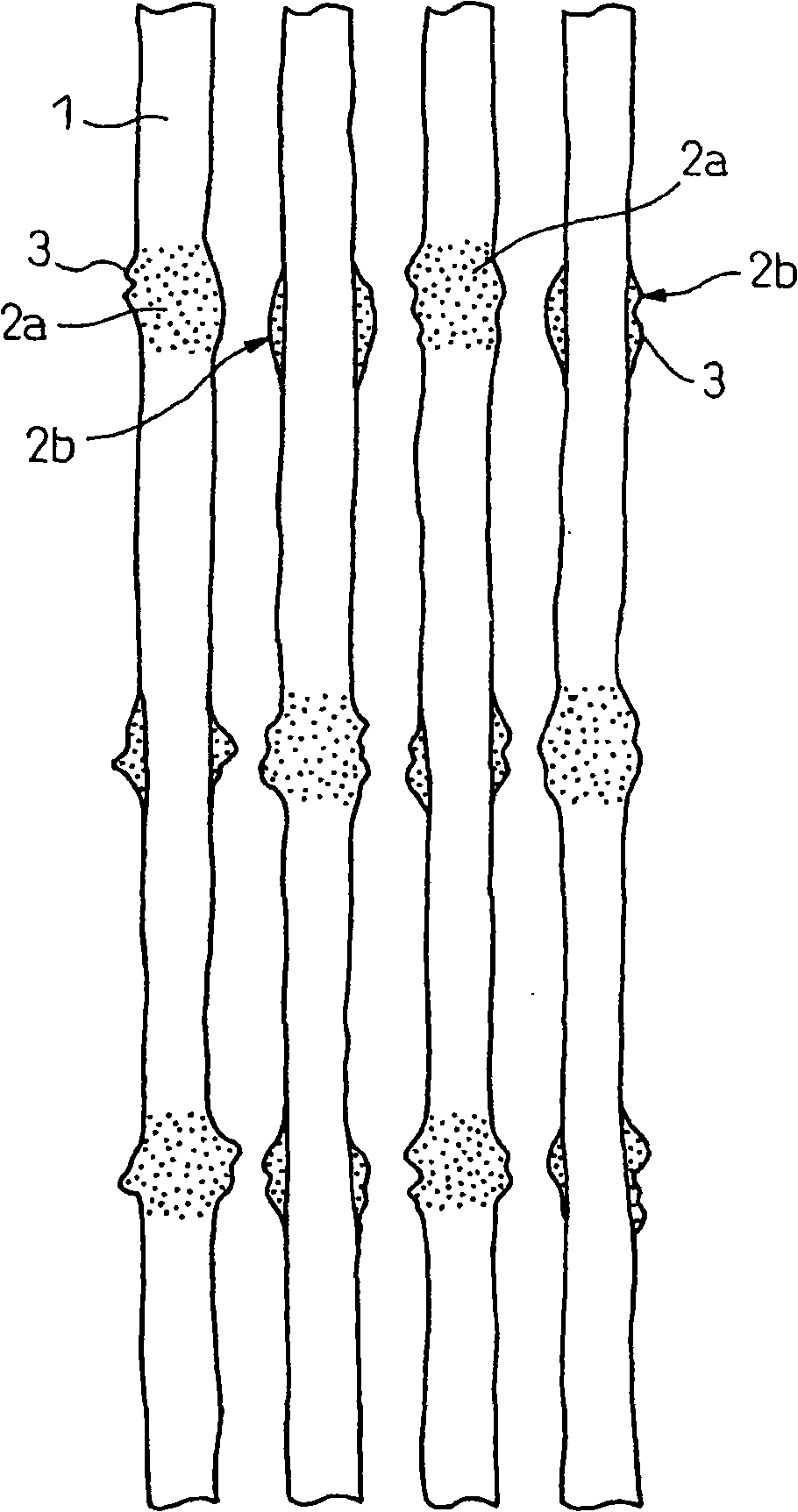

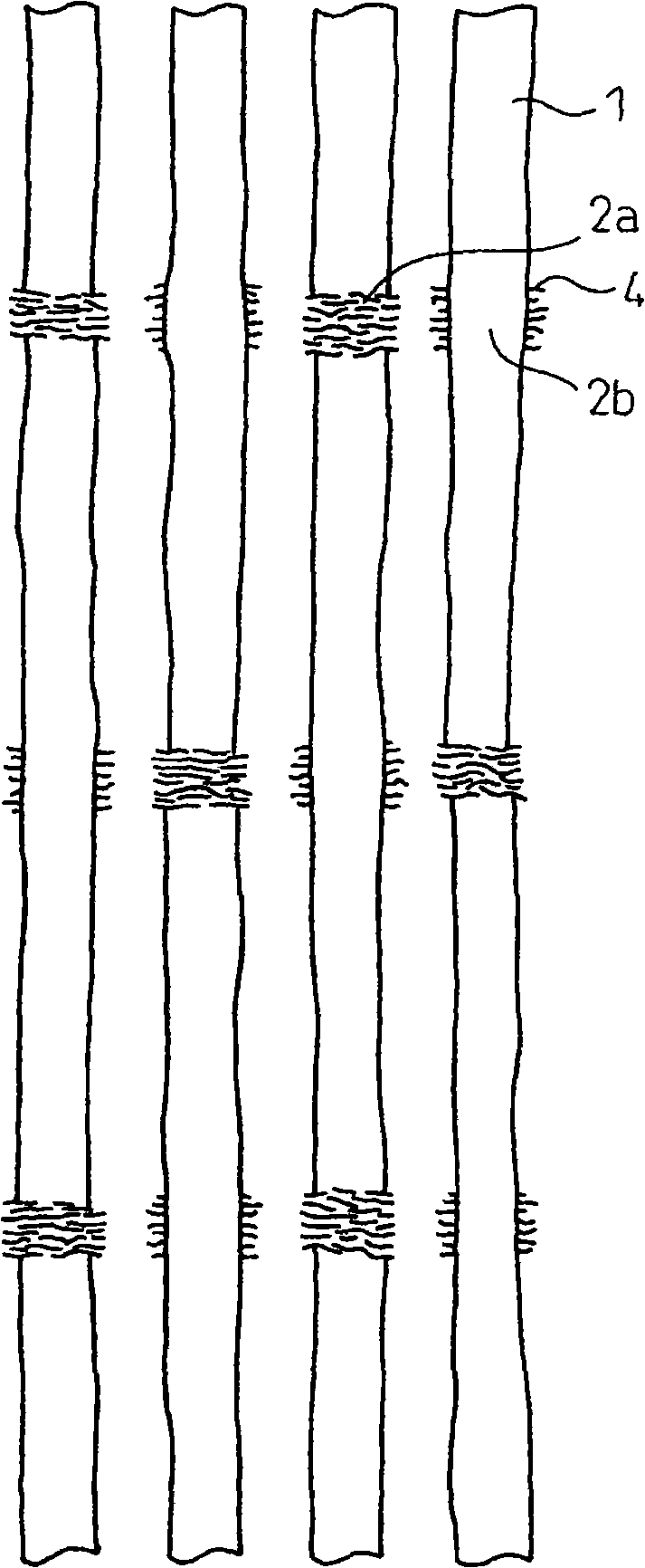

[0053] As the warp yarn, two polyethylene naphthalate multifilament yarns (1670dtex / 250 filaments, melting temperature: 272°C, trademark: Teonex, manufactured by Teijin Textile Co., Ltd.) were paralleled and twisted with a single yarn. A cord obtained by twisting 40 times / 10cm and double twisting 40 times / 10cm. In addition, as the weft yarn, low melting point nylon (110dtex / 12 filaments, melting temperature: 125° C., trademark: Flow M, manufactured by Unichika Fiber Co., Ltd.) was used.

[0054] 1500 warp yarns were aligned and warped, and the warp yarns were beaten up at intervals of 1.0 cm with the weft yarns to weave a coarse mesh fabric with a width of 160 cm and a length of 1500 mm.

[0055] The 1st adhesive treatment solution is based on epoxy compound (trademark: Denakol, manufactured by Nagase Chemical Industry Co., Ltd.) 3g (solid content) / liter, blocked isocyanate compound (trademark: S-3, manufactured by Meisei Chemical Industry Co., Ltd.) 12g (solid content) compo...

Embodiment 2

[0062] An adhesive-impregnated fiber cord was produced in the same manner as in Example 1. However, as the warp, an aramid multifilament yarn (1670 dtex / 1000 filaments, thermal decomposition start temperature: 500° C., trademark: Towellon, manufactured by Teijin Towellon Co., Ltd.) was used instead of the polyethylene naphthalene dicarboxylic acid used in Example 1. Glycol ester multifilament yarn.

[0063] In the first and second heat treatments, the weft yarn made of low-melting-point nylon is melted and self-ruptured, and a covering layer is formed on the intersecting portion of the warp yarn and the weft yarn, thereby forming protrusions at this portion. The adhesion amount of the weft residue on the warp was 0.2% by mass relative to the mass of the warp. In addition, the occurrence of bonding between the warp yarns by the adhesive was not observed.

[0064] The adhesive strength of the obtained adhesive-impregnated fiber cord was 201 N / cm, which was practically sufficie...

Embodiment 3

[0066] An adhesive-impregnated fiber cord was produced in the same manner as in Example 1. However, carbon multifilament yarn (2000dtex / 3000 filaments, decomposition start temperature of 500°C or higher, trademark: "Tenax" manufactured by Toho Tenax Co., Ltd.) was used instead of polyethylene naphthalate for warp used in Example 1. Alcohol ester multifilament yarn.

[0067] After the first and second heat treatments, the weft yarn made of low-melting-point nylon melts and breaks itself, adheres to the intersecting portion of the warp yarn and the weft yarn to form a covering layer, and forms protrusions at this portion. The adhesion amount of the weft residue was 0.1% by mass relative to the warp mass. The occurrence of bonding between the warp yarns by the adhesive was not observed. The adhesive strength of the obtained adhesive-impregnated fiber cord was 210 N / cm, which was practically sufficient as the adhesive strength of a practical reinforcing fiber cord.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com