Lever type electrical connector

An electrical connector and connector technology, which is applied in the direction of connection, parts and circuits of connecting devices, and can solve problems such as difficulty in precise design of levers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

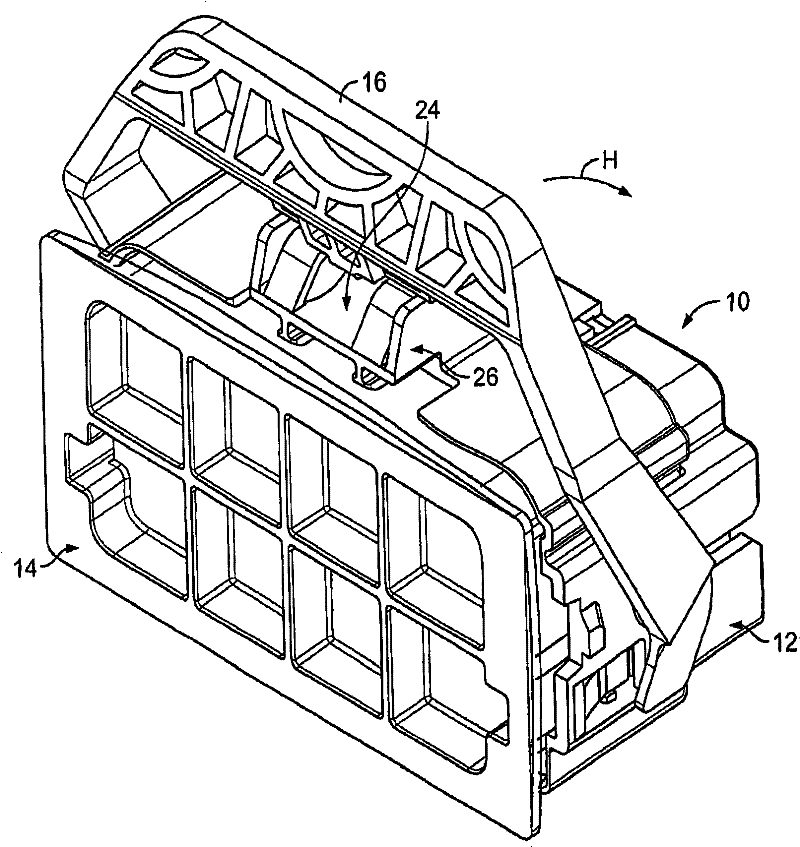

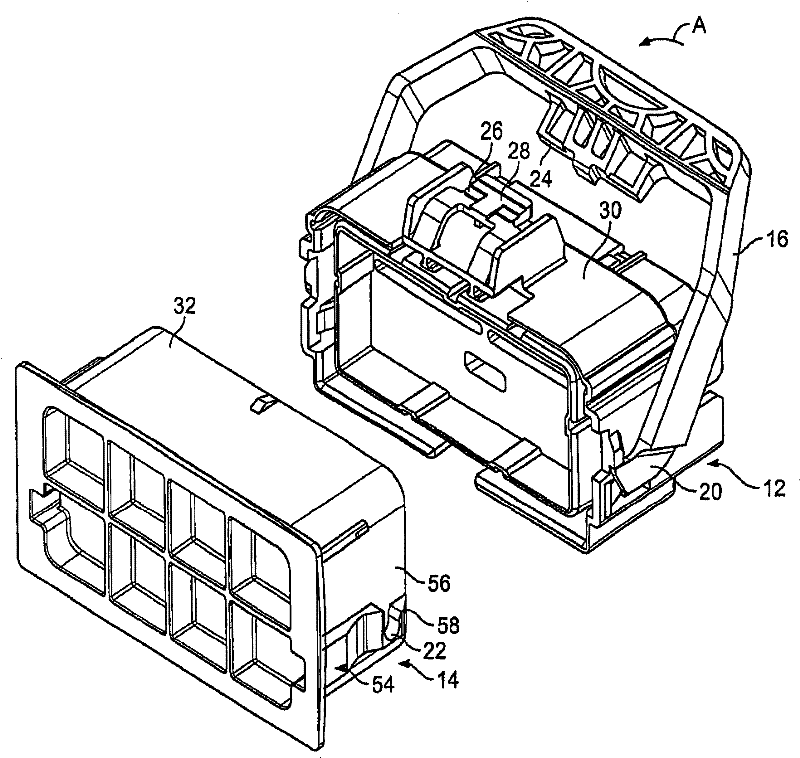

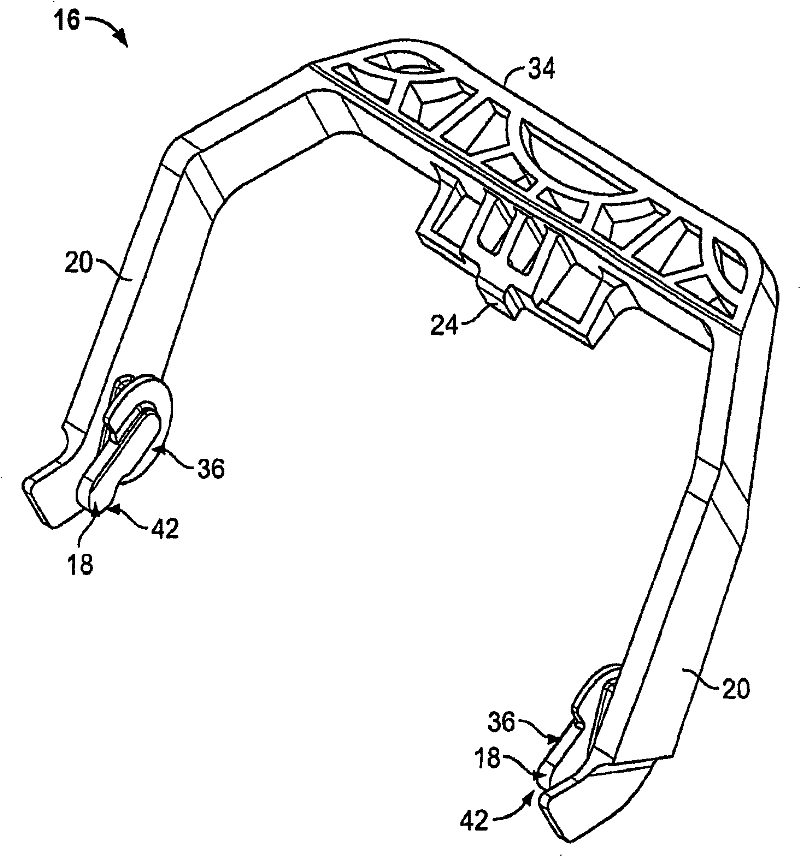

[0046] Referring to the attached drawings for more detail, first figure 1 and figure 2 A lever-type electrical connector assembly 10 is shown including a first connector or housing 12 and a second connector or head 14 . Each connector 12 and 14 includes a plurality of electrical contacts (not shown) received therein. Preferably, the assembly 10 includes more than 90 electrical contacts and is at least 70mm wide, 60mm long and 60mm high when assembled. In a preferred embodiment, the connector 10 may include 98 electrical contacts and is configured as a harness connector for a diesel engine; however, other uses, sizes and configurations of the connector 10 are also possible of.

[0047] Connectors of this size and configuration typically require more than about 300 N of force to overcome friction and engagement forces in order to interface or disengage the header 14 and housing 12 . Therefore, the connector 10 further includes a first, pre-mating or release position ( fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com