Multifunctional special template for top angle

A multi-functional, top-cornered technology, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc., it can solve the problem that the vertical use of large formwork can not meet the different requirements of formwork height, horizontal plate formwork It is difficult to fix the problem and limit the development of the formwork, so as to achieve the effect of simple structure, difficult disassembly and easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

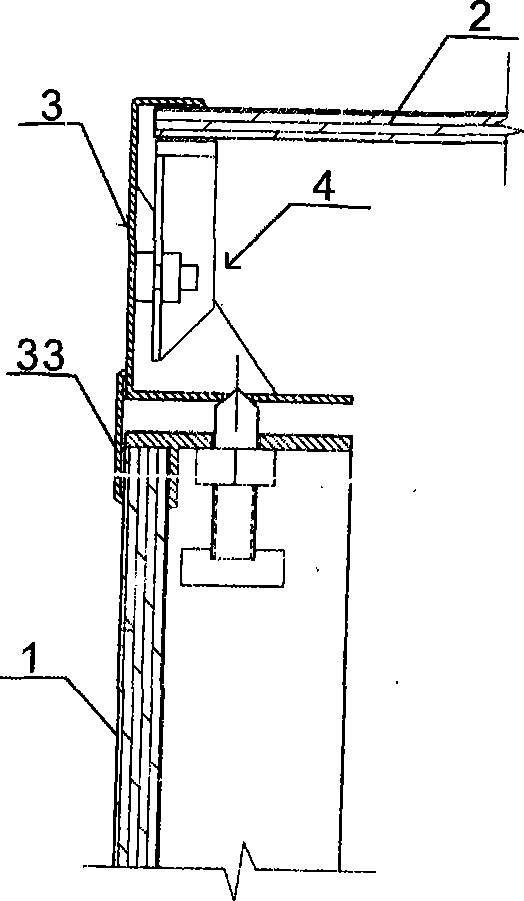

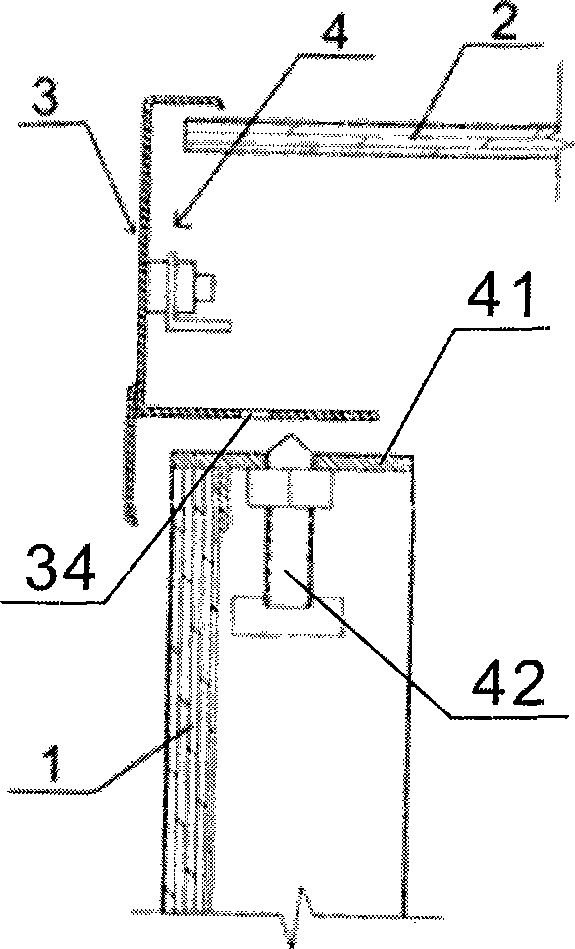

[0018] Please refer to the attached figure 1 and figure 2 , a special formwork for multifunctional corners, including a corner formwork 3 for connecting a large vertical formwork 1 and a horizontal floor formwork 2 and an adjustment device 4 for adjusting the height of the corner formwork, the height of the corner formwork The position adjusting device 4 is arranged at the bottom of the corner formwork 3 .

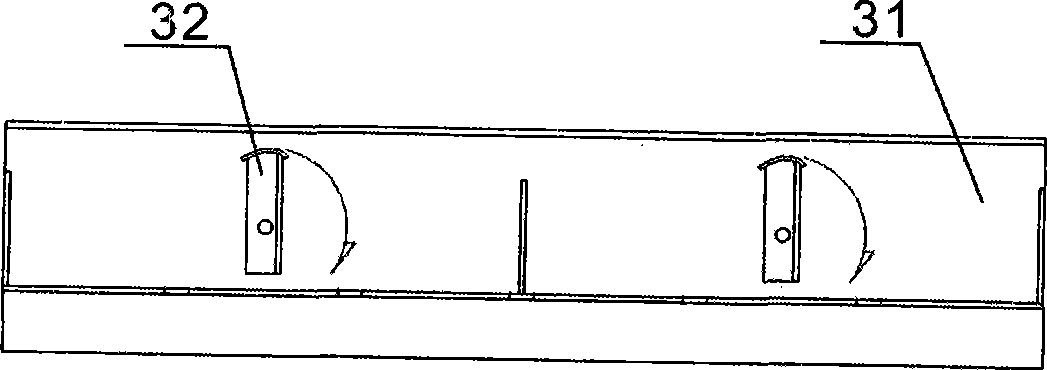

[0019] Please refer to the attached image 3 , Figure 4 and Figure 5 The top corner formwork 3 is provided with a longitudinal section of a "C"-shaped structural groove 31, and the "C"-shaped structural groove 31 includes a top plate 311 and a bottom plate 312 parallel to each other, and a side perpendicular to the top plate 311 and the bottom plate 312 Wall 313; the rotating top plate 32 that is used to fix the horizontal floor template 2 is arranged in this structural groove 31; Inside of the C"-shaped structural groove; multiple rotating top plates 32 are instal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap