Paper-insulating copper-silver alloy transposition semi-hard conducting wire wrapped by self-sticking ethylidene ether lacquer

A technology of acetal paint and paper insulation, applied in the direction of insulated conductors, metal/alloy conductors, insulated cables, etc., can solve the problems of transformer damage, coil deformation, complex structure, etc., achieve good electrical and thermal conductivity, mechanical properties do not decline, The effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

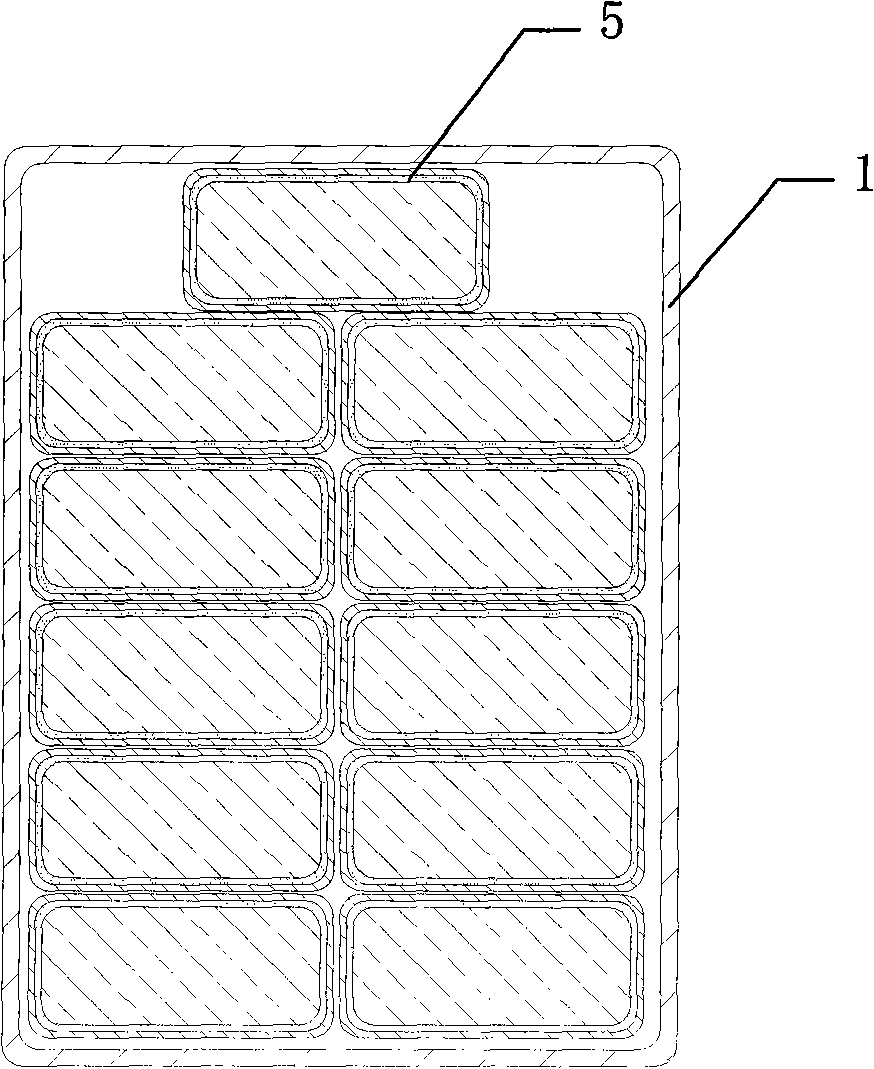

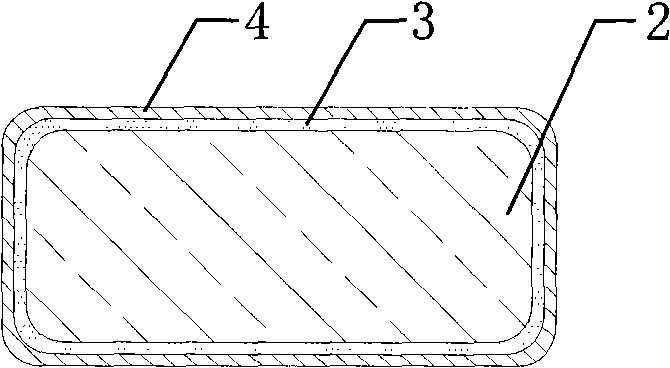

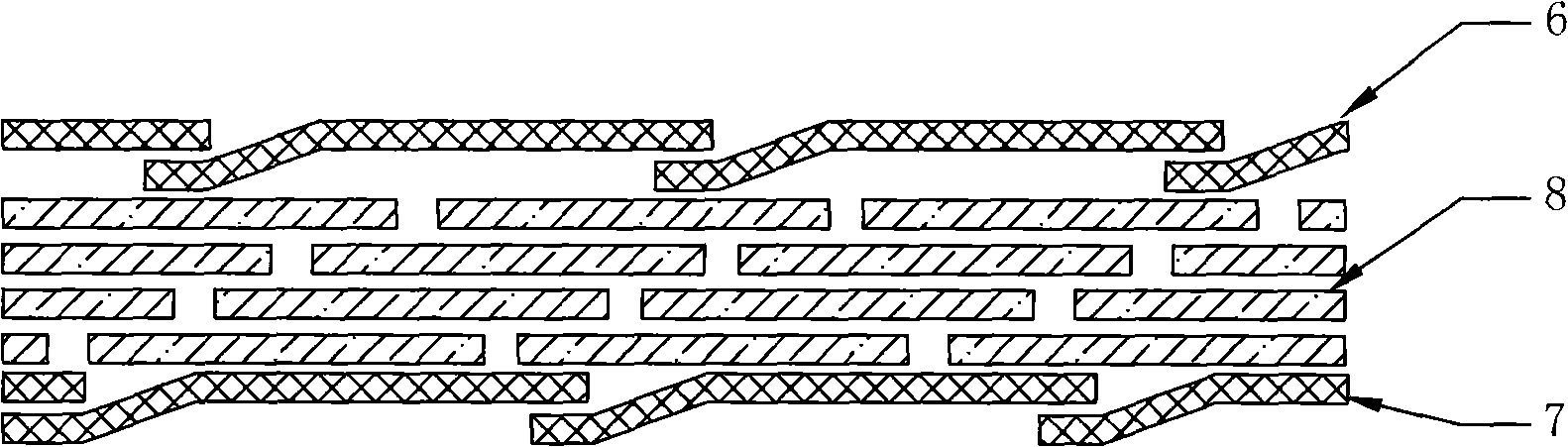

[0011] See figure 1 , the present invention comprises enameled wire 5 and insulating paper 1, and insulating paper 1 is wrapped on the outside of enameled wire 5, and enameled wire 5 comprises metal conductor 2 and paint film, and paint film layer comprises base paint layer 3 and top coat layer 4, and base paint layer 3 coats On the outside of the metal conductor 2, a topcoat layer 4 is coated on the outside of the base paint layer 3, and the metal conductor 2 is a copper-silver alloy conductor. In the copper-silver alloy conductor 2, the silver content is 0.8-2‰; the base paint layer 3 is acetal paint; the top paint layer 4 is self-adhesive paint; the number of enameled wires in the transposed wire is determined according to actual use requirements.

[0012] The paper-insulated self-adhesive acetal enamelled copper-silver alloy transposed semi-rigid wire of the present invention, the metal conductor of which is made of copper-silver alloy, is produced by up-drawing continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com