High-voltage energy-storage hydraulic work device

A working device and high-pressure energy storage technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of endangering the safety of hydraulic turbine equipment, many pipe joints, and easy leakage, so as to facilitate installation and maintenance. The effect of stable system pressure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

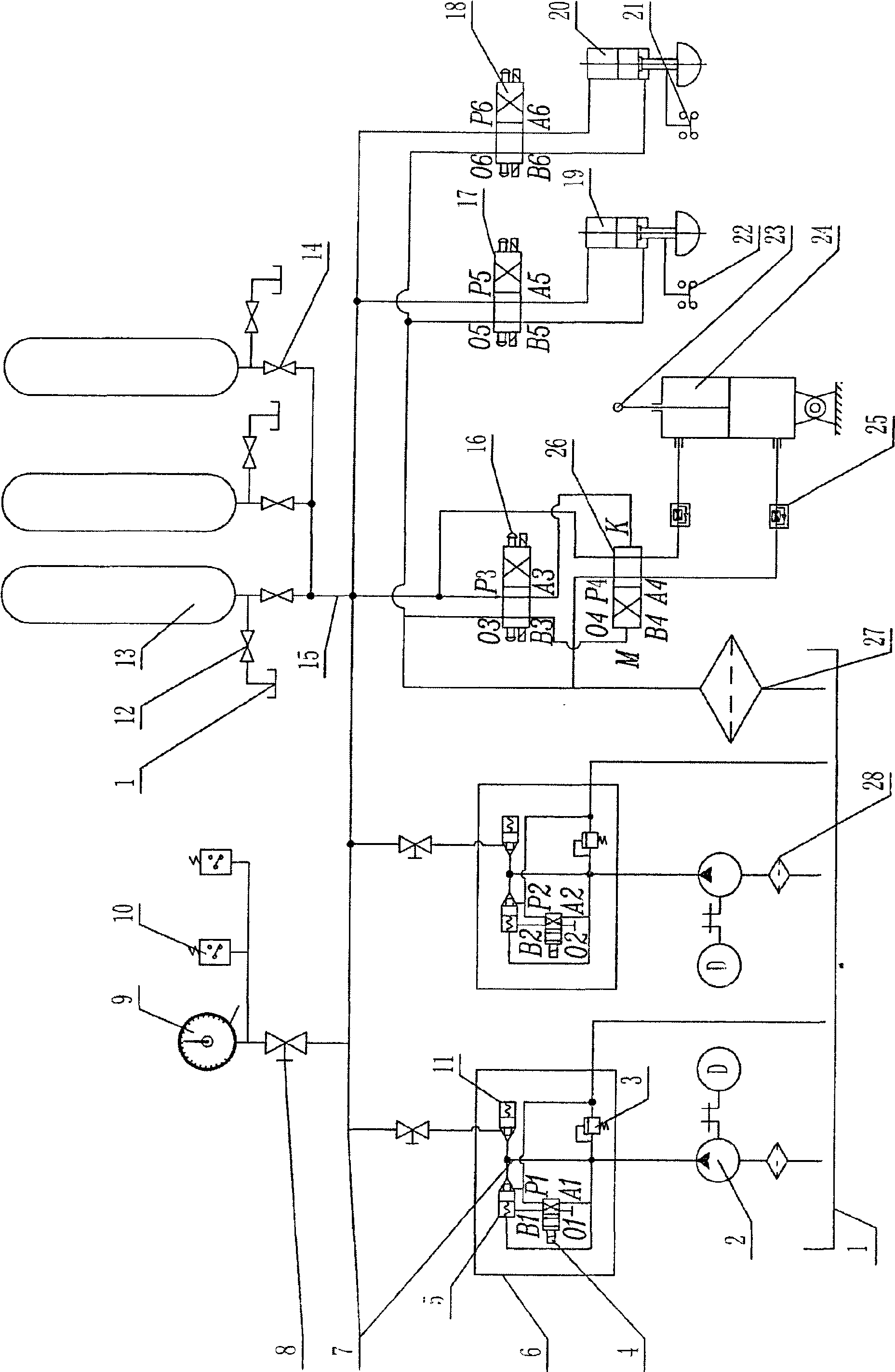

[0007] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0008] As shown in the figure, the high-pressure accumulating hydraulic working device of the present invention includes a hydraulic source supply pipeline formed by connecting an oil pump output pipe (7) and an accumulator output pipe (15) in parallel, and is characterized in that: the hydraulic source One of the supply lines passes through the first two-position four-way reversing valve A (26) to control the first working oil cylinder D (24) to realize the drive control of the opening and closing of the butterfly valve (23), and the other way passes through the second two-position four-way reversing valve The valve B (17) controls the second working oil cylinder E (19) to realize the pulling and inserting of the butterfly valve lock pin (22), and the third way controls the third working oil cylinder F (20) through the third two-position four-way rever...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap