Rice beverage and manufacturing method thereof

A rice beverage and rice technology, applied in the field of rice beverage and its manufacturing, can solve problems such as poor beverage stability, and achieve the effect of overcoming insufficient heat treatment strength and increasing alpha degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0064] Puffed Rice Noodles 19g 28g

[0065] 41 grams of white sugar 55 grams

[0066] Non-dairy creamer 13g 17.5g

[0067] Sodium Isovitamin C 0.20g 0.30g

[0068] Ethyl Maltol 0.03g 0.06g

[0069] Sodium tripolyphosphate 0.28g 0.31g

[0070] Compound Phosphate Sodium Hexametaphosphate 0.052g 0.165g

[0071] Sodium pyrophosphate 0.018g 0.005g

[0072] Molecular Distilled Monoglyceride 0.9g 1.1g

[0073] Sucrose fatty acid ester 0.72g 0.84g

[0074] Carrageenan 0.30g 0.44g

[0075] Microcrystalline Cellulose 1.3g 1.6g

[0076] Water 923.2 grams 894.68 grams

Embodiment 1

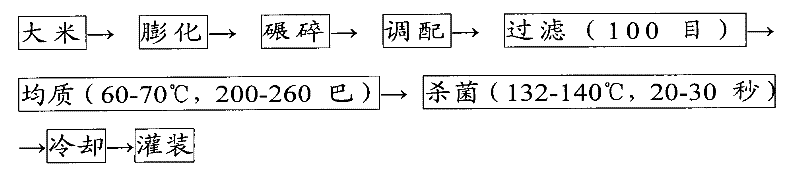

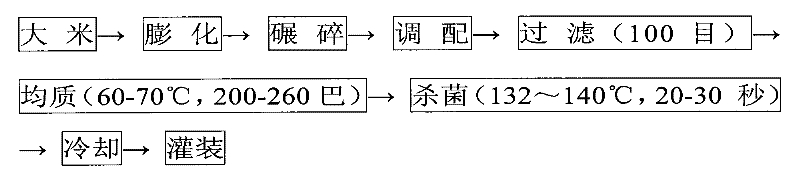

[0078] The rice drink of embodiment 1 is prepared according to the following procedures:

[0079] [The first process - rice puffing]

[0080] Weigh 500 grams of rice, put it into the popcorn machine (CQ-DP type, Zhengzhou Trading Co., Ltd.), tighten the lid, put it on the fire and start heating, and turn the popcorn machine at the same time to prevent the rice from being partially overheated and coking. Pay attention to observe the value of the pressure gauge. When the pointer of the pressure gauge reaches about 0.4MPa, stop heating. At this time, the pressure inside the machine will still rise. When it rises to about 0.8MPa, open the cover for puffing.

[0081] [Second process - rice crushing]

[0082] Put the puffed rice in the first process into a high-speed tissue masher for crushing operation, and pay attention to control the time for about 3 minutes to ensure that the particle size of the puffed rice flour is ≤160 mesh, accounting for more than 86%.

[0083] [The third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com