Process for manufacturing bank-type commutator segment group with dovetail

A manufacturing process and a commutator segment technology, which is applied to the manufacturing process field of a belt-type commutator segment group with a dovetail for commutators, can solve the problems of high production cost, uneven width of inner hooks, influence on bonding strength, etc. High utilization rate, uniform inner hook width, and the effect of ensuring mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

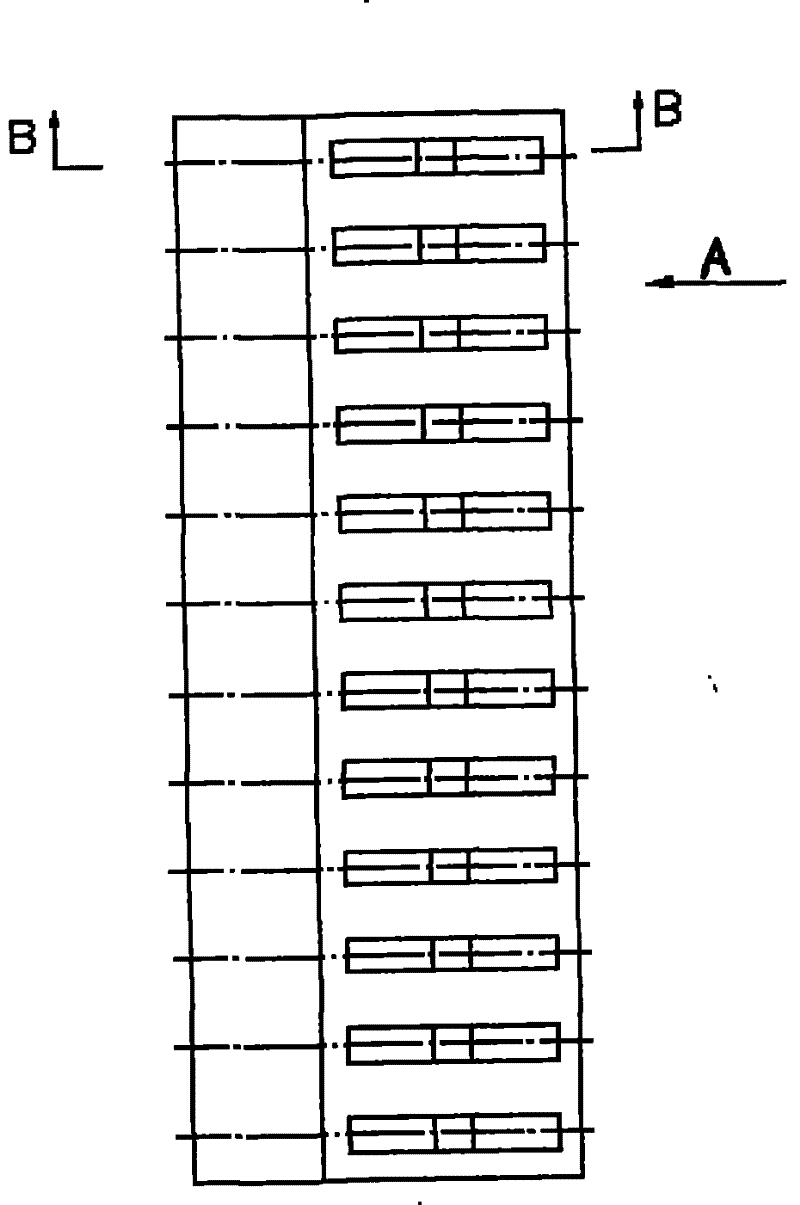

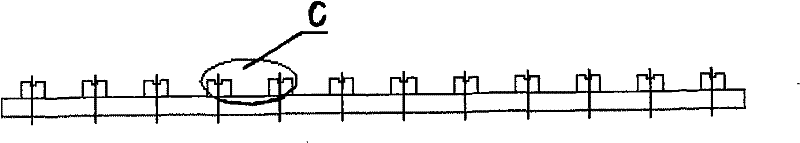

[0014] The manufacturing process of the band commutator segment group with dovetail of the present invention is: first copper wire rod (i.e. solid circular tubular copper material) is carried out warm extruding treatment (using warm extruded copper material continuous extruder, warm extruding temperature is generally 100-200 degrees Celsius, which is a known technology) to form a belt-type commutator group, and then perform a drawing process on the belt-type commutator group (that is, a drawing process, the drawing equipment used is a copper wire drawing machine), Then, the belt-type commutator group with dovetail (ie, inner hook) 9 is obtained through the cold extrusion treatment of rolling gear rolling on the belt-type commutator group after (once) drawing, such as figure 1 , figure 2 , image 3 , Figure 4 shown.

[0015] The rolling g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com