Quaternized Cellulose Ethers for Personal Care Products

A personal care, cellulose ether technology, applied in skin care preparations, hair care, cosmetic preparations, etc., can solve the problems of reduced foaming, poor viscosity maintenance, poor thickening efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

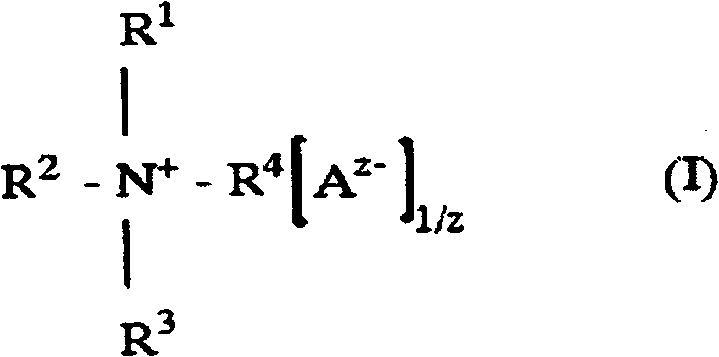

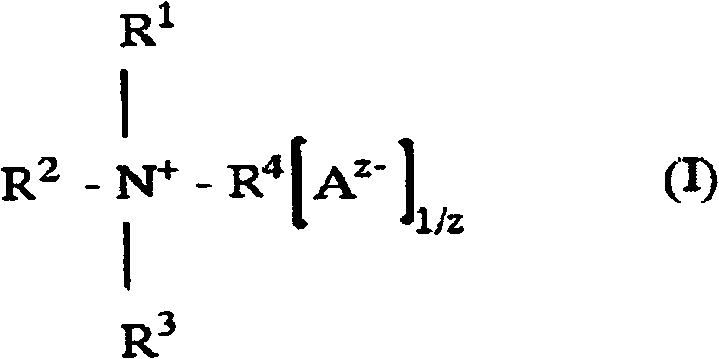

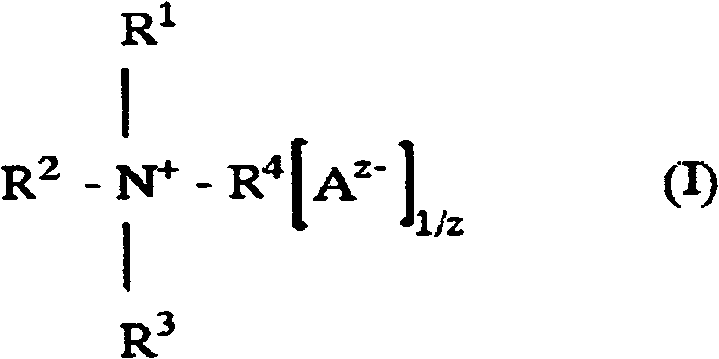

Method used

Image

Examples

Embodiment 1

[0032] The quaternized cellulose ethers of the present invention are obtained in combination with the various components listed in Table 1 below:

[0033] Table 1

[0034]

batch 1

batch 2

batch 3

(Compared)

batch 4

batch 5

(Compared)

batch 6

batch 7

HEC 1

60

--

--

--

--

--

--

HEC 2

--

80

40

--

300

40 *

80

HEC 3

--

--

--

60

--

--

--

360

480

240

--

--

--

460

6% isopropyl alcohol (IPA) in water

--

--

--

--

1805

--

--

0% IPA in water

--

--

--

--

--

241

--

2% IPA in water

--

--

--

360

--

--

--

25% by weight sodium hydroxide (NaOH)

...

Embodiment 2

[0044] Following essentially the protocol of Example 1, the batches listed in Table 1 were prepared and characterized. The results are listed in Table 2:

[0045] Table 2

[0046]

[0047]Compounds of batches 1-7 may be represented by formula (II) above, wherein n is about 500-2000, x is selected such that the hydroxyethyl substitution M.S. is about 2.0 to 2.4, and y and z are selected such that the batch Subcompounds have the nitrogen percentages and levels of hydrophobic substitution (HS) listed in Table 2. Nitrogen content, %N: average weight percentage of nitrogen per anhydroglucose repeating unit determined by titration using an automated Buchi Kieldahl distillation unit and by an automated titrimeter. The average number of moles of hydrophobic substituents per mole of anhydroglucose units is expressed as hydrophobic substitution (HS). Using nuclear magnetic resonance ( 1 H-NMR, 400 MHz, using sodium trimethylsilyl propionate as a standard and heavy water as...

Embodiment 3

[0049] The personal care composition of the present invention comprises the quaternized cellulose ether from Example 1 with the components listed in Table 3:

[0050] table 3

[0051] Batch A

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com