Method for preparing cathode material LiCo<x>Ni<y>Mn<z>O<2> of lithium ion battery using carbon dioxide as catalyst

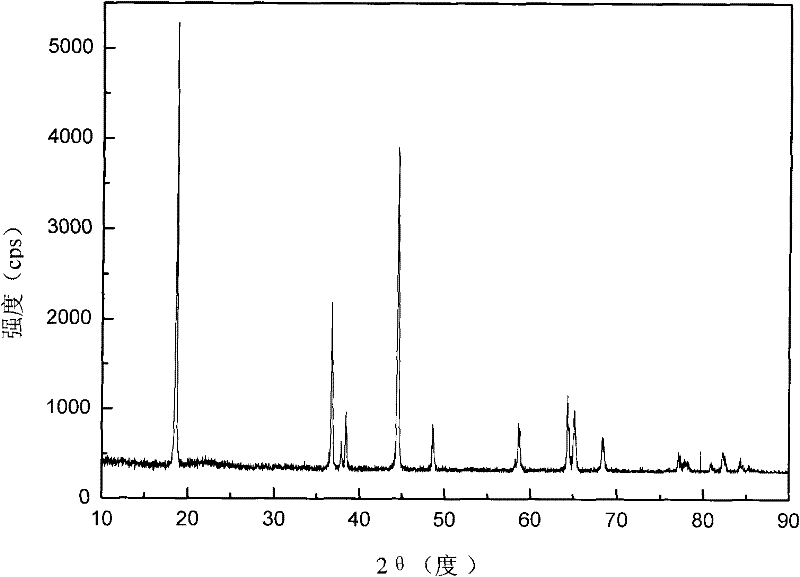

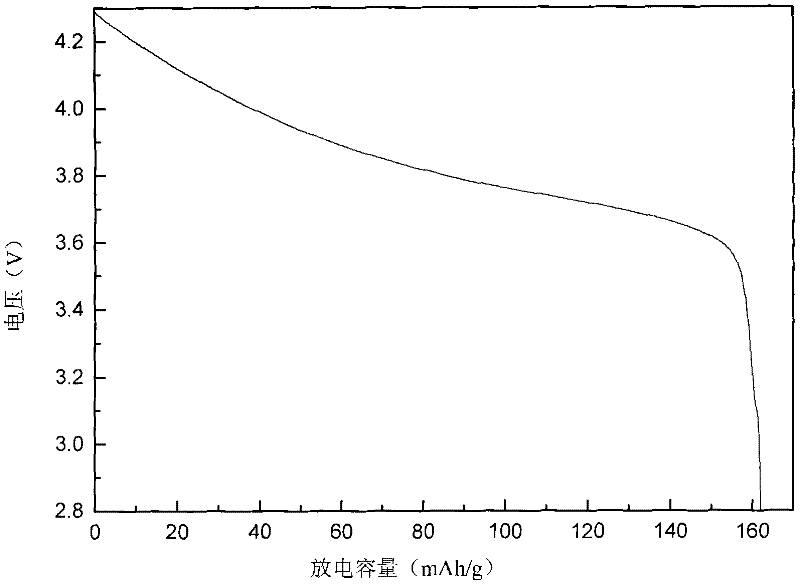

A lithium-ion battery and carbon dioxide technology, applied in the direction of physical/chemical process catalysts, battery electrodes, chemical instruments and methods, etc., can solve the problems of poor crystallinity of positive electrode materials, fewer charge and discharge cycles, and low alkalinity of carbonate solutions, etc. problem, to achieve the effect of increasing the concentration, reducing the amount of residual ions, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific implementation mode 1: In this implementation mode, carbon dioxide is used as a catalyst to prepare lithium-ion battery cathode material LiCo x Ni y mn z o 2 The method is as follows: 1. According to the chemical formula LiCo x Ni y mn z o 2 , respectively weigh cobalt salt, nickel salt and manganese salt according to the molar ratio of Co element, Ni element and Mn element as x:y:z, and then dissolve them in distilled water to obtain system 1, where 0≤x, 0≤y , z≤1, x, y, z are not 0 simultaneously; Two, sodium carbonate and ammoniacal liquor are dissolved in distilled water, obtain system 2, wherein the amount of cobalt ion, nickel ion and manganese ion total substance in system 1 and sodium carbonate The molar ratio of substances is (x+y+z): 1; 3. Add system 1 and system 2 to distilled water under the conditions of carbon dioxide atmosphere, water temperature of 30°C-60°C, and pH value of 8-9, and then Stir for 12 hours under the condition of stirring ...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that the cobalt salt described in step 1 is cobalt sulfate, cobalt acetate or cobalt nitrate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the cobalt salt described in step 1 is a combination of any two of cobalt sulfate, cobalt acetate and cobalt nitrate. Others are the same as in the first embodiment.

[0014] In the cobalt salt described in this embodiment, the two components are mixed in any ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com