Subsurface electric gripper

An electric and gripper technology, which is applied in the field of reactor engineering, can solve the problems of large size, inability to use, and inapplicability of the device, and achieve the effect of small size and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

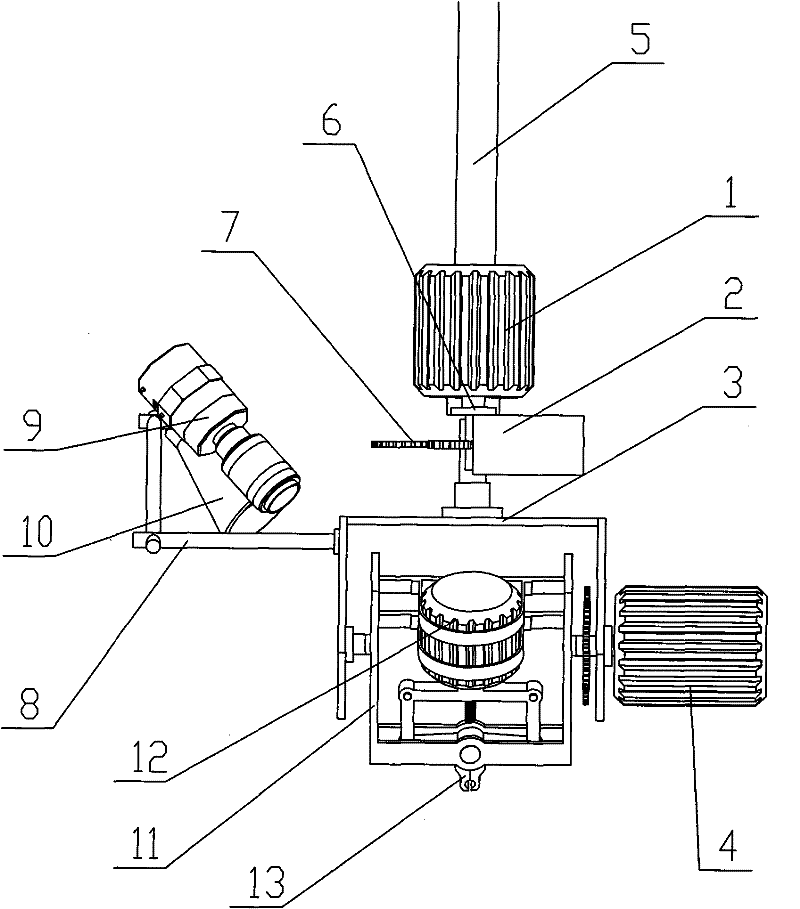

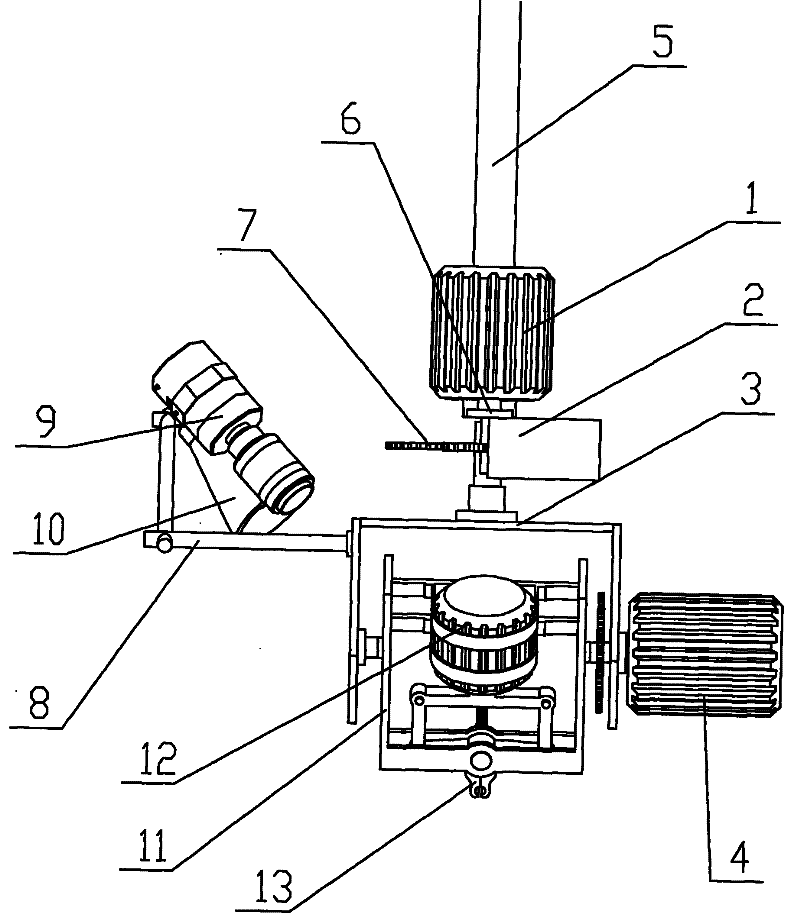

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0011] The device is installed on the crane by the long rod 5 in the device, and the device is sent to the underwater designated position by the crane. The long rod 5 is fixedly connected with the sealed gearbox 2 through the flange 6, and the sealed gearbox 2 is connected with the horizontal rotating frame 3 through the shaft, the bearing and the gear pair 7 in the gearbox, and is supported on the horizontal rotating frame 3. On the sealed gearbox 2, the horizontal rotation drive motor 1 fixed on the gearbox 2 is brought to the horizontal rotation frame 3 to rotate through the gear pair 7 in the transmission gearbox 2, so as to realize the rotation of the gripper in the horizontal plane.

[0012] The vertical rotation drive motor 4 is supported on the horizontal rotation frame 3, and is connected with the vertical rotation frame 11 through bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com