Silicon slag treating process in zirconyl chloride production

A technology of zirconium oxychloride and processing technology, which is applied in the field of zirconium oxychloride-acid-alkali production technology, can solve the problems of low yield rate of zirconium oxychloride, affect the economic benefits of enterprises, waste of resources and other problems, and achieve improvement The effect of improving yield, reducing waste of resources and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example 1

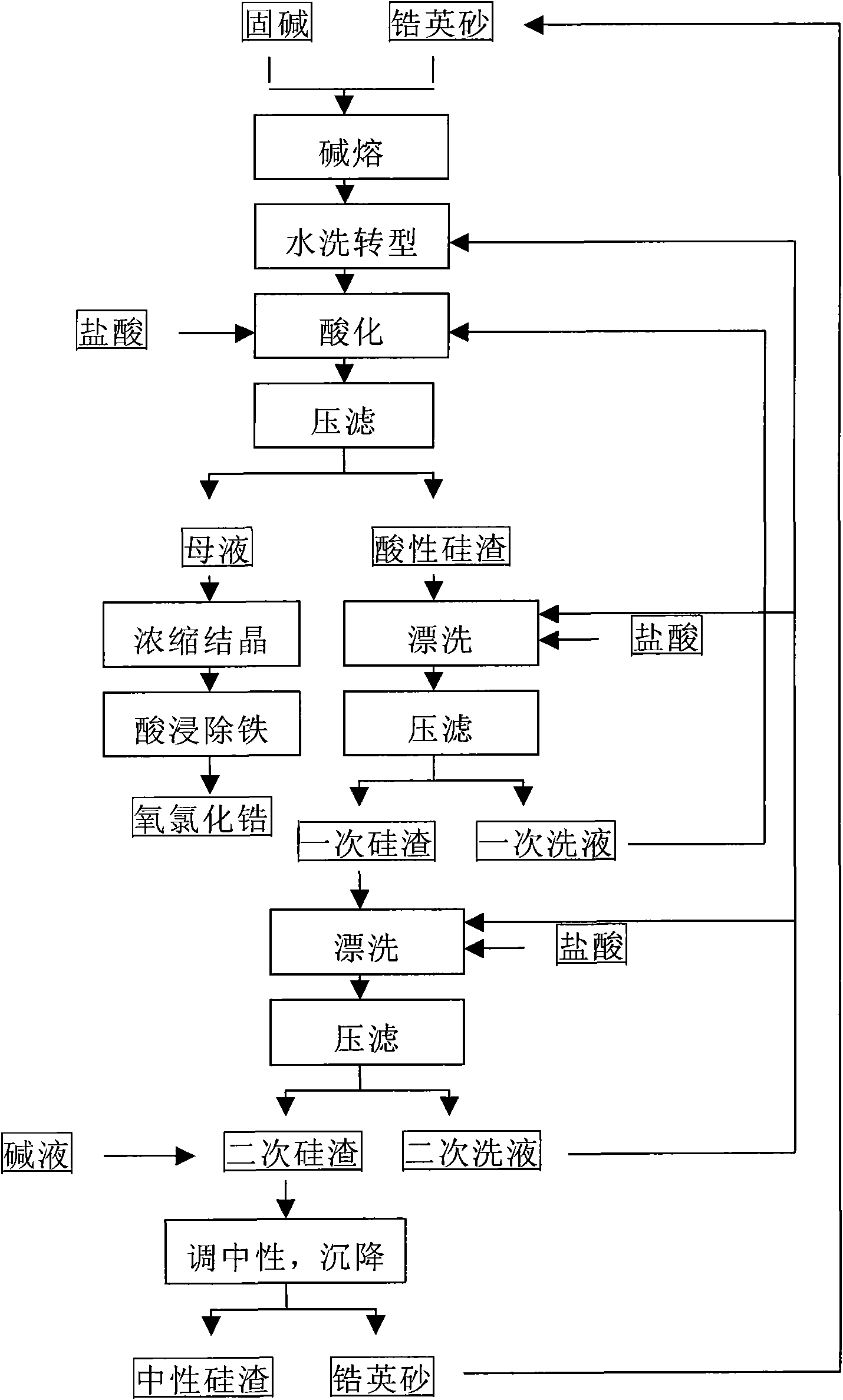

[0020] Such as figure 1 As shown, (1) The zircon sand and solid caustic are alkali-melted, undergo a water washing transformation process, water washing to remove silicon, transformation to remove sodium, after an acidification process, add hydrochloric acid to acidify, and then add a silicon slag lotion and / or two The secondary silicon slag washing liquid dilutes the acidified material liquid, and the volume ratio of the primary silicon slag washing liquid and / or the secondary silicon slag washing liquid and the acidified material liquid is 0.8-1.2:0.8-1.2, separated by a filter press process to obtain a zirconium-containing mother liquor And acidic silicon slag, the zirconium-containing mother liquor is concentrated and crystallized and pickled to remove iron to obtain zirconium oxychloride; (2) acidic silicon slag is rinsed with 0.5N hydrochloric acid and filtered to obtain primary silicon slag and primary silicon slag Washing liquid; the primary silicon slag...

Example Embodiment

[0021] Example 2

[0022] (1) The zircon sand is melted in alkali, washed with water to remove silicon, transformed to remove sodium, and acidified with hydrochloric acid, then add a silicon slag lotion to dilute the acidified material liquid. The volume ratio of the primary silicon slag washing liquid to the acidified material liquid is 1:1. Press filtration and separation to obtain zirconium-containing mother liquor and acidic silicon slag. The zirconium mother liquor is concentrated and crystallized to produce zirconium oxychloride products. For every 1 ton of zirconium oxychloride produced, about 0.5 tons of acidic silicon slag is produced; (2) Acidic silicon slag Use 3N concentrated crystalline condensed hydrochloric acid to rinse and filter to obtain primary silicon slag and primary silicon slag washing liquid. The zirconium content in the primary silicon slag washing liquid is 20-25g / L, and the primary silicon slag washing liquid is reused to the acidification process; (3) ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap