Automotive body robot flexible welding system applicable to mixed line production of multiple vehicle types

A technology of automobile body and welding system, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of incomplete application, and achieve the effect of effective function, fast and accurate positioning movement, and enlarged working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

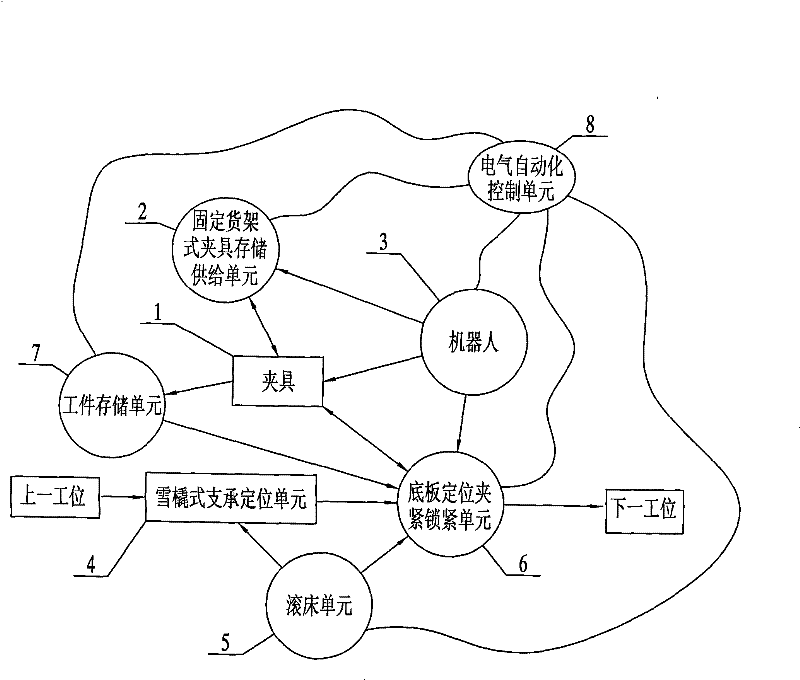

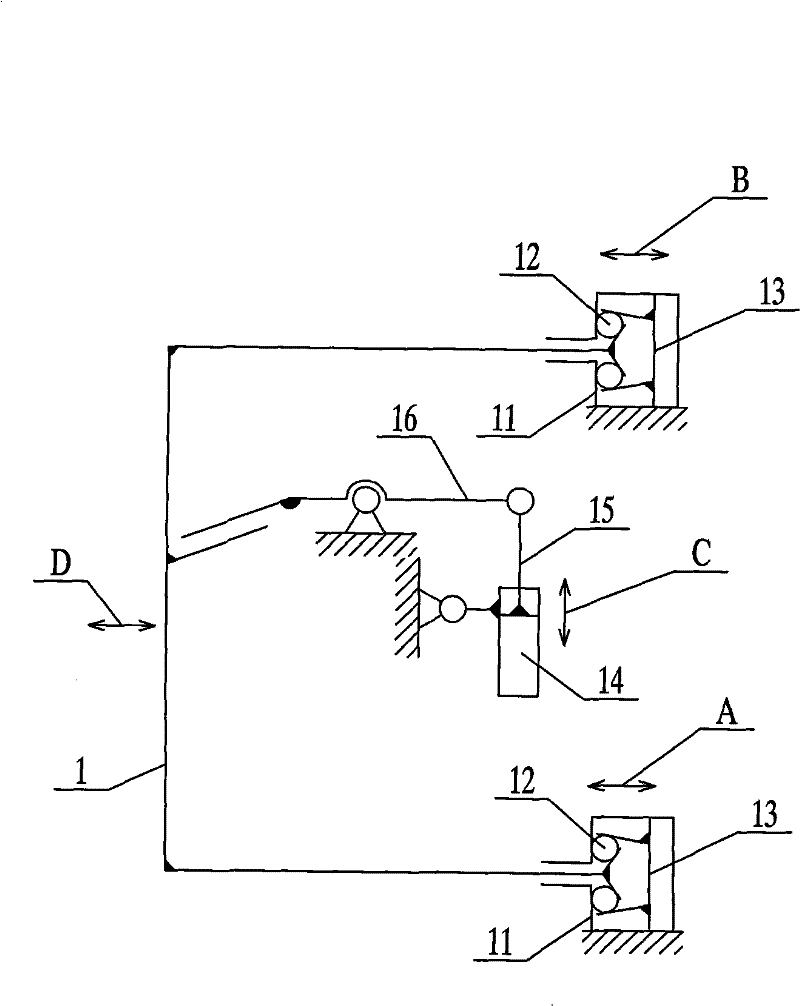

[0024] Refer to the attached figure 1 , The invention discloses a robot flexible welding system suitable for multi-vehicle mixed line production of automobile bodies. The system includes a fixed shelf fixture storage and supply unit 2 for storing multiple fixtures 1; it is installed on a moving slide table for grabbing the fixture 1 to realize the automatic quick change of the workpiece and fixture 1, and for grabbing the robot welding torch A robot 3 performing welding operations; a sled supporting and positioning unit 4 for supporting and positioning workpieces and for transferring workpieces; a rolling bed unit 5 for positioning and clamping sled supporting and positioning units 4 and moving them along the production line; The locking robot 3 is released to the fixture 1 of the fixture working position and is used to position and clamp the base plate positioning and clamping locking unit 6 of the workpiece; the workpiece storage unit 7 for storing the workpiece and feeding ...

Embodiment approach

[0027] As a preferred embodiment of the present invention, its specific scheme is as follows:

[0028] See figure 1 , composition of the present invention:

[0029] 1, including a fixed shelf fixture storage supply unit 2;

[0030] 2, including a robot 3;

[0031] 3. It includes a plurality of sled support positioning units 4;

[0032] 4, including a rolling bed unit 5;

[0033] 5, including a bottom plate positioning clamping locking unit 6;

[0034] 6, including a workpiece storage unit 7;

[0035] 7, including a set of electrical automation control unit 8.

[0036] A brief description of each of the above components is as follows:

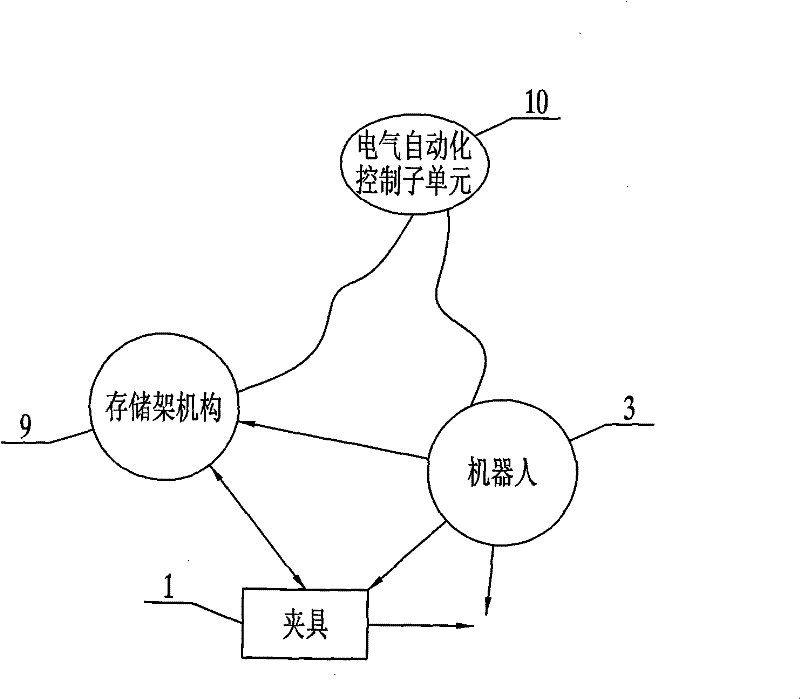

[0037]The fixed shelf fixture storage and supply unit 2 is a unit for storing all vehicle fixtures 1 in this area of the station. This unit is provided with 3 storage rack mechanisms 9 . The storage positions of the clamps 1 in the fixed-shelf clamp storage supply unit 2 are also the clamp switching positions, and they correspond one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com