Real-time imaging device for micropore evolution in alloy remelting and solidification

A real-time imaging, alloy technology, applied in the direction of using radiation for material analysis, furnace, lighting and heating equipment, etc., can solve the problems of high cost, difficult to observe the change of alloy remelting process, complicated test process, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

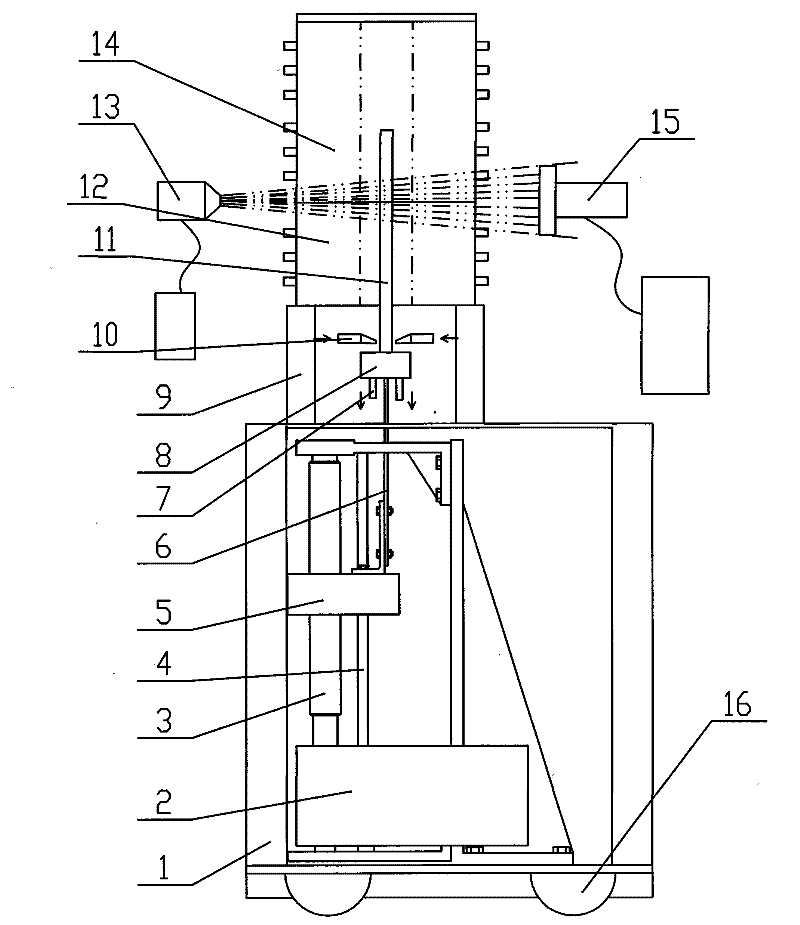

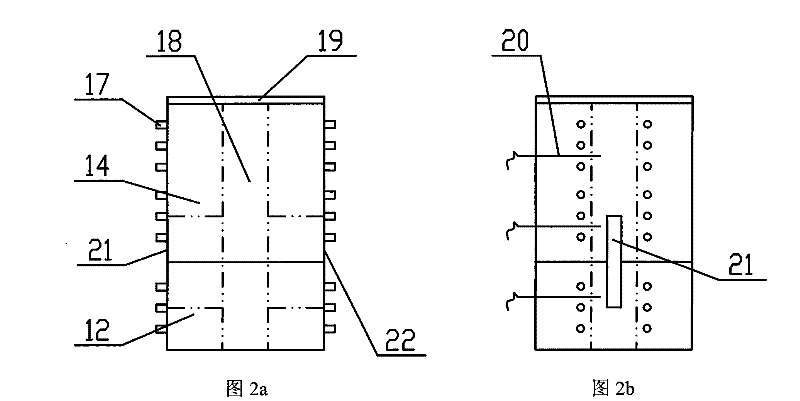

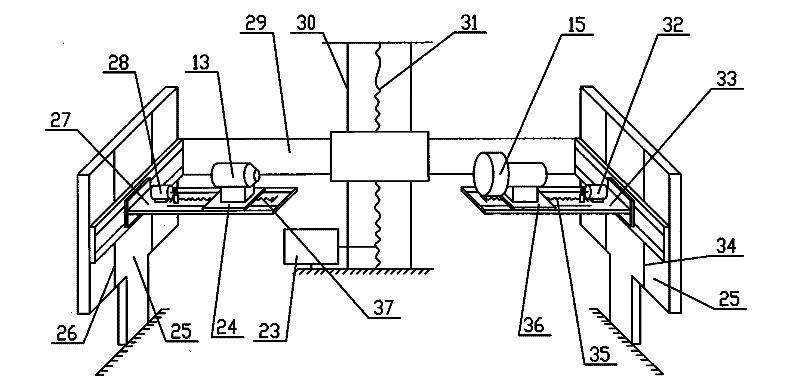

[0021] A real-time imaging device for micropore evolution in alloy remelting and solidification, including: a lifting device, a heating furnace, a micro-focus X-ray tube and a controller 13, and a device for receiving and processing micro-focus X-ray tubes emitted and passing through the alloy test A sample X-ray image and data analysis system 15 is provided with a sample ship 11 on the lifting platform 5 of the lifting device, and the sample ship 11 is located in the hearth of the heating furnace, and the sample ship 11 is formed by a U-shaped frame 40 and front skin 41, rear skin 42, front skin 41, rear skin 42 are attached to the front and rear sides of U-shaped frame 40 respectively, and U-shaped frame 40 and front skin 41, rear skin 42 The sample cavity 44 is enclosed and fastened with screws 38. The opening of the U-shaped frame 40 is upward, and the alloy sample is placed in the sample cavity of the sample ship. Since the gap after fastening is very small, after melting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com