Additive for preparing polysilicon etching chemical suede

An additive and silicic acid technology, which is applied in the field of additives for the preparation of chemical suede by polysilicon acid etching, can solve problems such as inconvenience of control, and achieve the effects of reducing energy consumption, moderating corrosion rate and improving suede quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

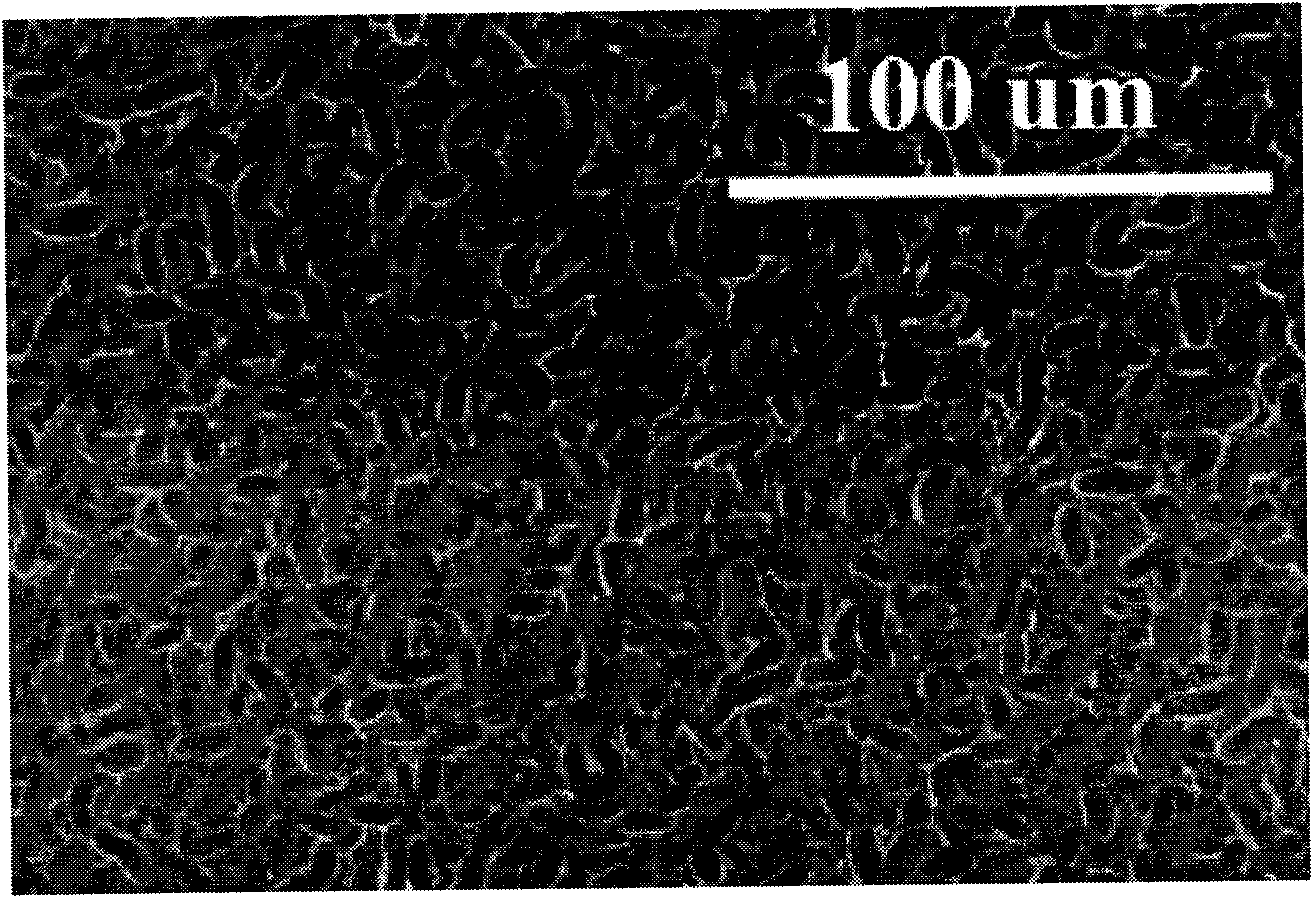

Image

Examples

Embodiment Construction

[0028] An additive for preparing polysilicon acid etching chemical suede, comprising an acid etching solution, in which the following components by volume percentage are added:

[0029] (1) Nitrogen-containing inorganic salts: 0.1-2%

[0030] (2) Silicon-based surfactant: 0.1-0.5%

[0031] The volume percentage is relative to the volume of the acidic corrosion solution.

[0032] The acidic etching solution is an etching solution composed of hydrofluoric acid, nitric acid and water.

[0033] The volume ratio of hydrofluoric acid, nitric acid and water in the acidic corrosion solution is 3:6:4.

[0034] The solution temperature of the additive is 8-20°C.

[0035] Nitrogen-containing inorganic salts are nitrates, nitrites or ammonium salts (such as sodium nitrate, sodium nitrite, potassium nitrate, potassium nitrite, ammonium sulfate, ammonium nitrate, ammonium nitrite, etc.); One or more of base siloxane and its derivatives.

[0036] When in use, the temperature of the addi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap