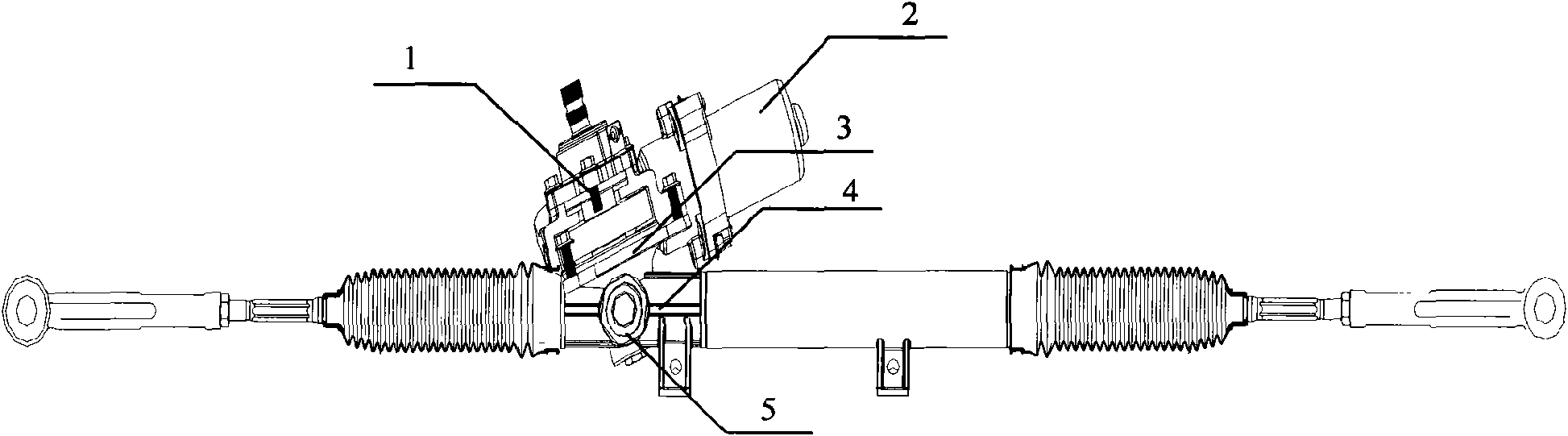

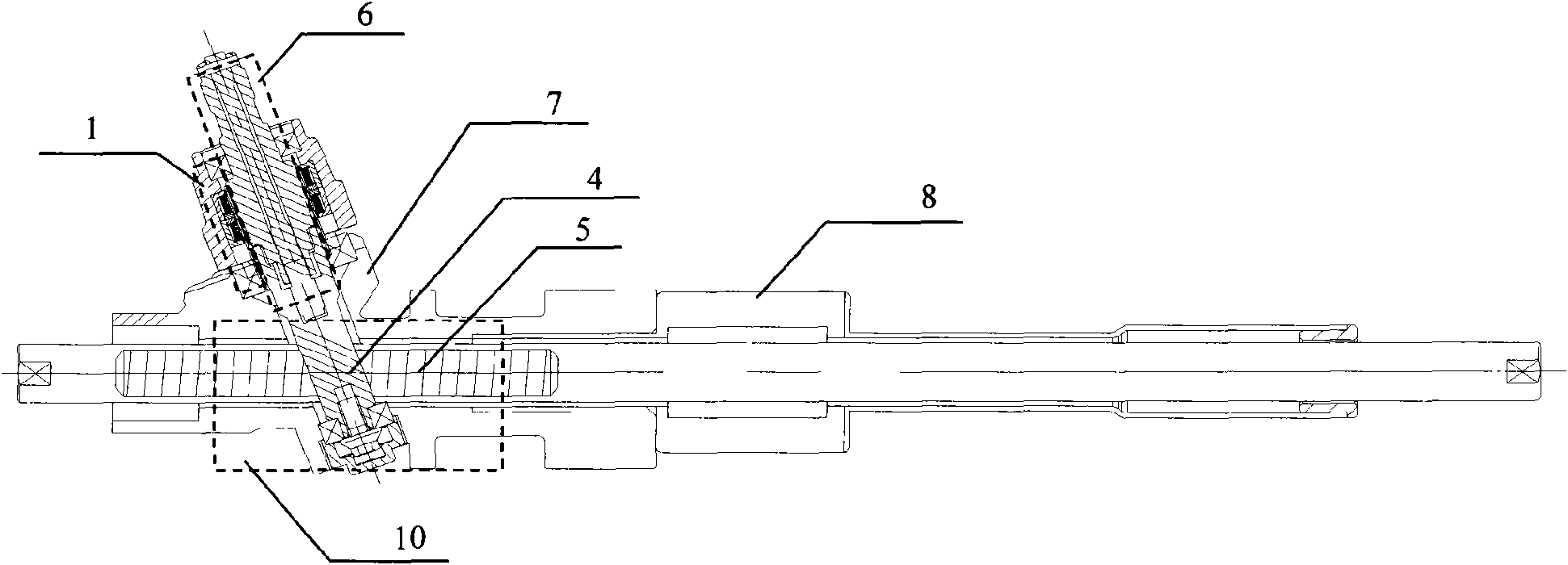

Electric power steering device

A technology of electric power steering and rotor, which is applied in the direction of electric steering mechanism, electromechanical device, electric device, etc., can solve the problems of DC motor power limitation, complex structure, easy to wear, etc., to save installation space, improve transmission efficiency, Effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

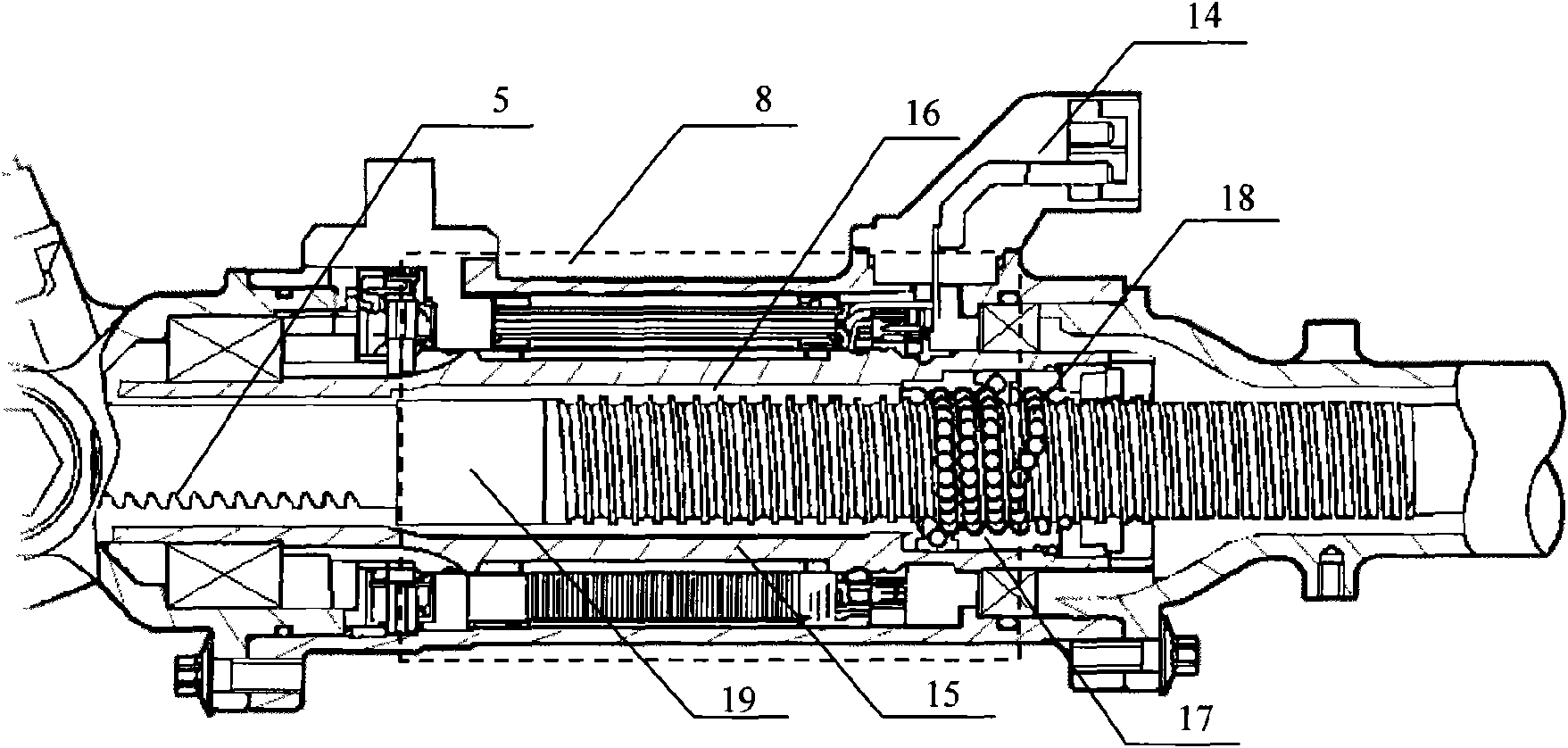

[0028] As another embodiment of the present invention, such as image 3 As shown in the schematic diagram of the assembly structure of the actuator and the drive mechanism, the actuator 10 includes a gear 4 and a rack 5, the gear 4 is socketed at the end of the steering main shaft 31, the first half of the rack shaft 19 is made into a rack form, the gear 4 and the rack 5 A unilateral meshing method is adopted between them, and the second half of the rack shaft 19 is made into a lead screw form, and the direct drive motor rotor 15 and the nut 16 are made into one body, and the direct drive motor rotor 15 is threaded with the rack shaft 19 through the nut 16. The bar part meshes and drives the tooth bar 5. As a preferred embodiment of the present invention, such as image 3 The nut part at the end of the direct drive motor rotor 15 shown is in the form of a slideway, and the slideway part of the nut 16 is in sliding engagement with the lead screw part of the rack shaft 19 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com