Coloring composition for forming red pixel, color filter and color liquid crystal display element

A coloring composition and pixel technology, which is applied to photosensitive materials, instruments, optical filters, etc. used in optomechanical equipment, can solve the problems of not being good enough, red reproduction domain reproduction difficulties, etc., and achieve the effect of excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0169] Add 0.5 parts by mass of 2,2'-azobisisobutyronitrile and 200 parts by mass of propylene glycol monomethyl ether acetate into a flask equipped with a condenser tube and a stirrer, and continue to add 15 parts by mass of methacrylic acid, N-benzene 20 parts by mass of maleimide, 55 parts by mass of benzyl methacrylate, 10 parts by mass of styrene, and pentaerythritol tetrakis(3-mercaptopropionate) as a molecular weight regulator (manufactured by Sakai Chemical Industry Co., Ltd., Product name: PEMPII-20P) 2 parts by mass, ventilated with nitrogen. Thereafter, the reaction solution was stirred slowly to raise the temperature of the reaction solution to 80° C., and kept at this temperature for 5 hours to perform polymerization to obtain a resin solution (solid content concentration=33.3% by mass). Mw=25000 and Mn=12000 of the obtained resin. This resin solution was referred to as "resin solution (B-1)".

Embodiment 1

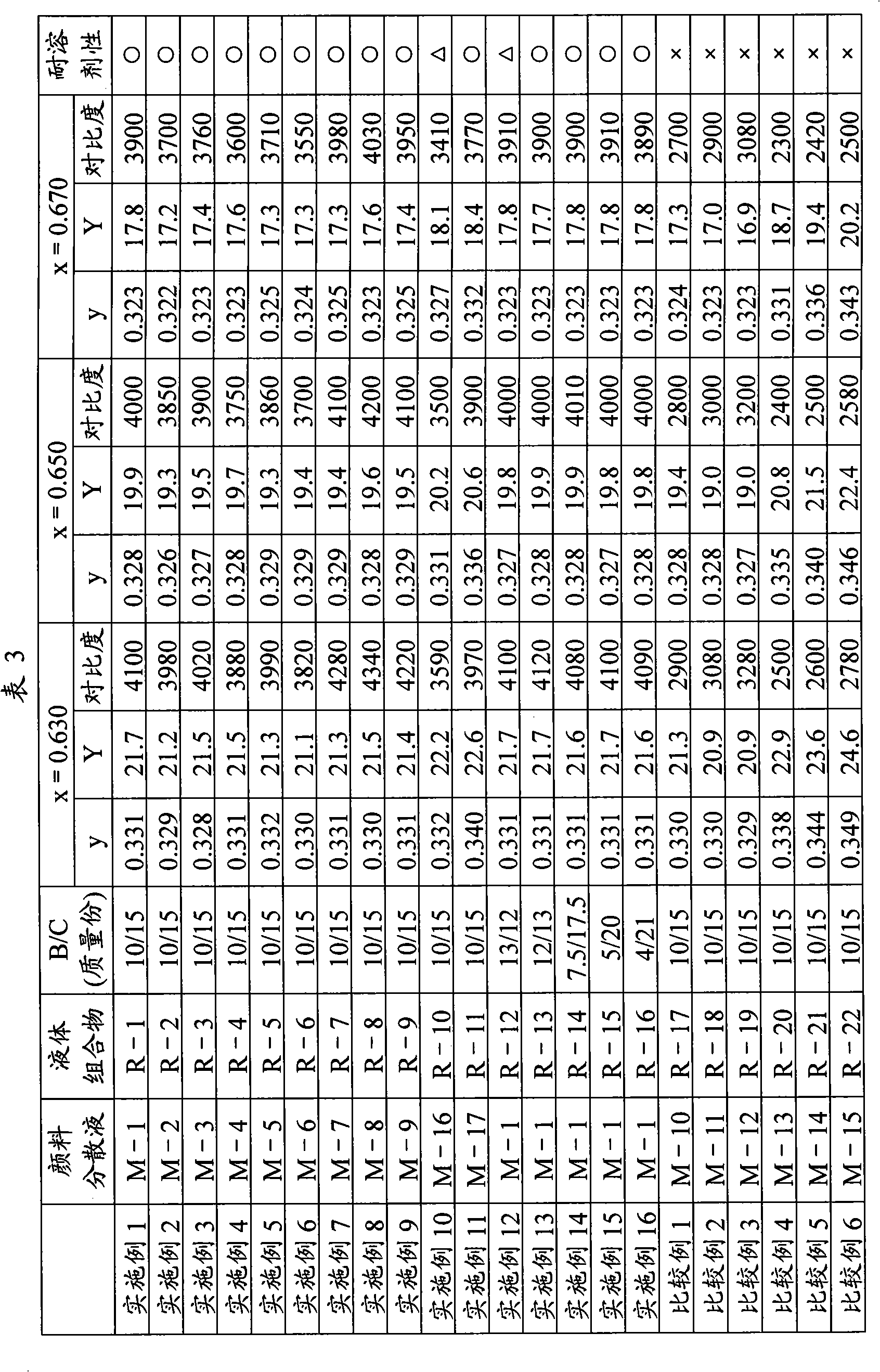

[0171] 100 parts by mass of pigment dispersion liquid (M-1) as (A) colorant, 10 parts by mass (in terms of solid content) of resin solution (B-1) as (B) alkali-soluble resin, 15 parts by mass of dipentaerythritol hexaacrylate as a functional monomer, (D) 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl)butane-1 as a photopolymerization initiator - 4 parts by mass of ketone, 1 part by mass of 4,4'-bis(diethylamino)benzophenone, and propylene glycol monomethyl ether acetate as a solvent are mixed to prepare a liquid combination with a solid content concentration of 25%. substance (R-1).

[0172] Regarding the liquid composition (R-1), a substrate for evaluation was produced and evaluated in the following procedure. The evaluation results are listed in Table 3.

[0173] Production of the substrate

[0174] Using a spin coater, the liquid composition (R-1) was applied to 3 pieces with the rotation speed as a variable to form SiO on the surface to prevent the dissolution of sodi...

Embodiment 2~27 and comparative example 1~11

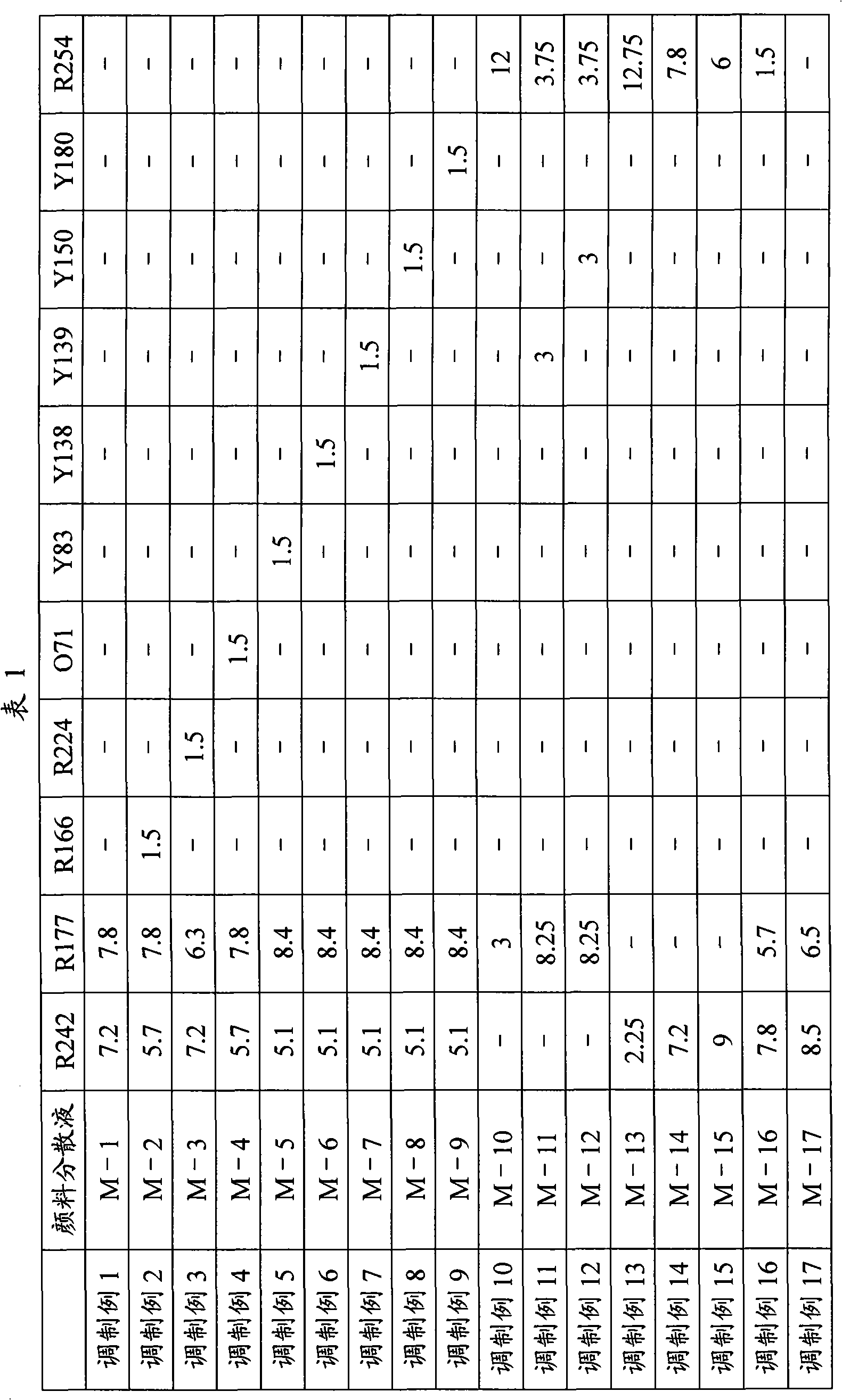

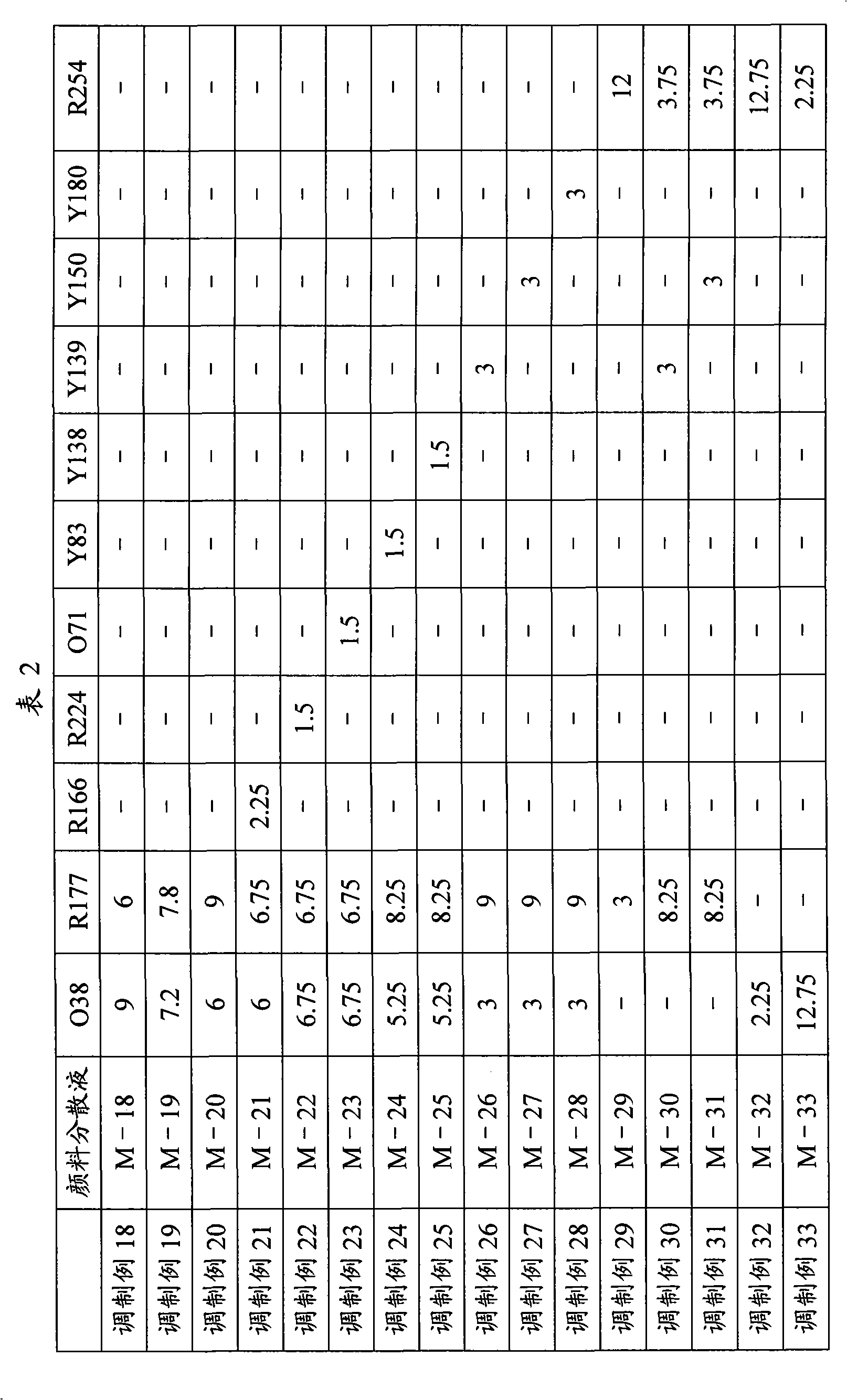

[0185] In Example 1, liquid compositions (R-2) to (R-38) were prepared in the same manner as in Example 1 except that the pigment dispersion liquid was replaced with those shown in Table 3 and Table 4.

[0186] Then, it evaluated similarly to Example 1 except having replaced liquid composition (R-1) with liquid compositions (R-2)-(R-38), respectively. The evaluation results are listed in Table 3 and Table 4. In addition, in the evaluation of the solvent resistance in Example 16, it was identified that a film remained on the unexposed portion of the substrate.

[0187]

[0188]

[0189] In Table 3 and Table 4, "B / C (parts by mass)" means content (parts by mass) of (B) alkali-soluble resin and (C) polyfunctional monomer.

[0190] It can be seen from Tables 1 to 4 that if Pigment Red 177 and C.I. Pigment Red 242 or C.I. Pigment Orange 38 are used as colorants, a dark hue close to that of a CRT can be reproduced and high contrast can be obtained.

[0191] In contrast, it c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap