Electrical secondary pre-wiring method of high-voltage switch cabinet

A high-voltage switchgear, electrical secondary technology, applied in switchgear, electrical components and other directions, can solve the problems of small electrical box space, high labor intensity, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The electrical secondary pre-wiring method of the high-voltage switchgear provided by the embodiment of the present invention includes the following steps:

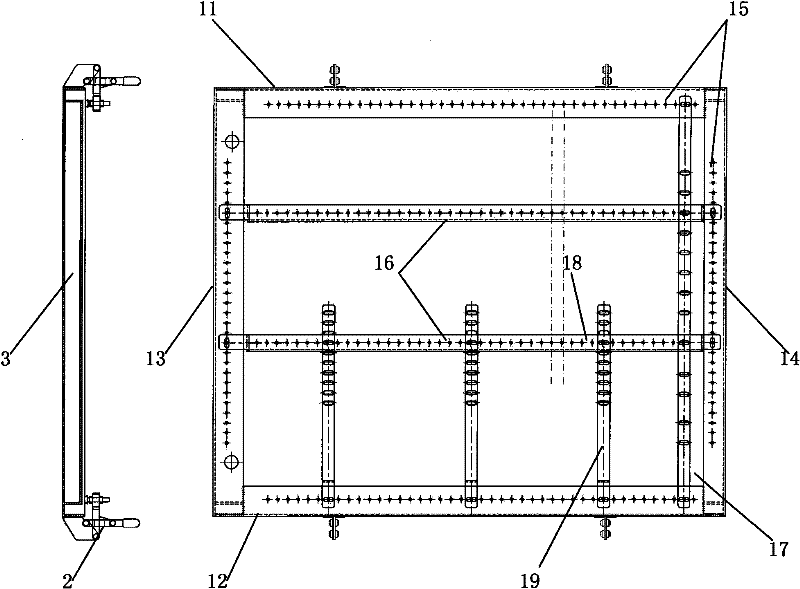

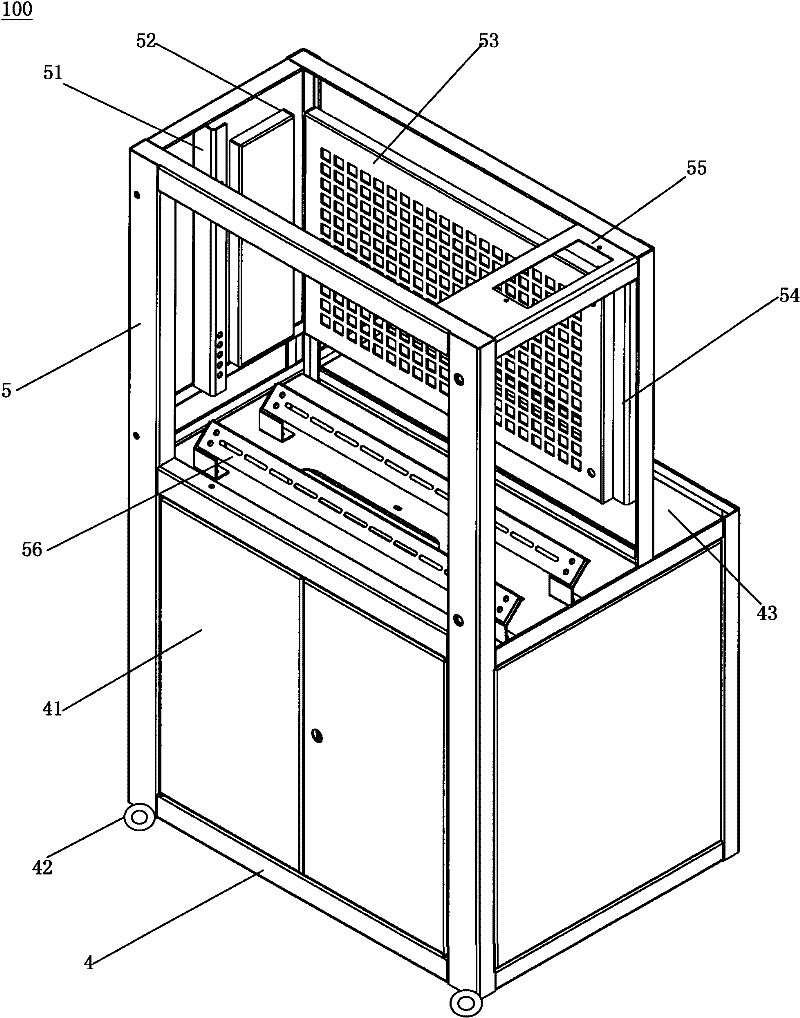

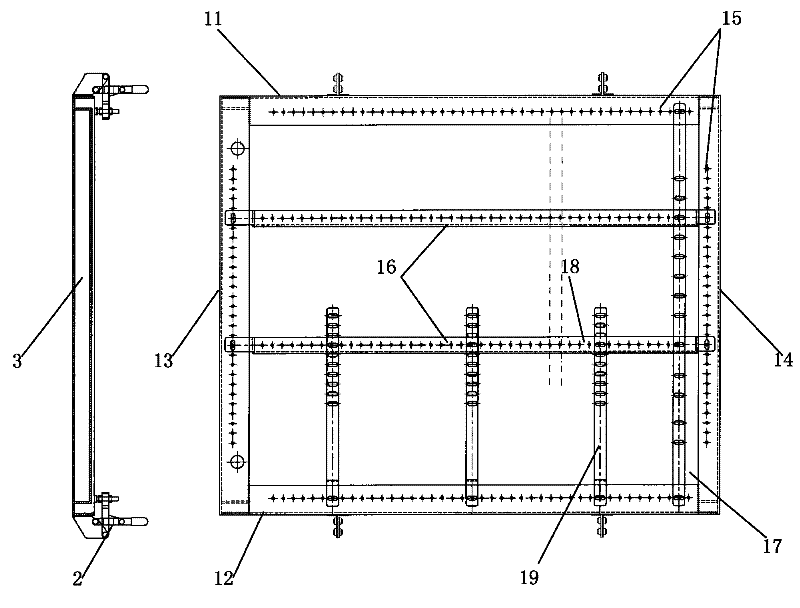

[0030] (1) Design, according to user requirements and relevant operating specifications, prepare high-voltage switchgear electrical wiring mold box, high-voltage switchgear electrical wiring mold base and component models to complete the design of electrical secondary pre-wiring design drawings, and determine the layout of all secondary electrical components model specification and the discharge position of the wiring harness;

[0031] (2) The electrical secondary pre-wiring of the analog panel. When the electrical components have not arrived and the panel of the high-voltage switchgear cabinet is not completed, according to the requirements of the electrical secondary pre-wiring design drawing, first install the electrical wiring mold on the analog panel and the high-voltage switchgear. Install the component model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com