Cast templet

A technology for casting molds and castings, which is applied to casting molding equipment, mold boxes, manufacturing tools, etc., can solve the problems of increased grinding costs, large increase in casting scrap rate, and high labor intensity of workers. The effect of reducing the labor intensity of workers and improving the appearance quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

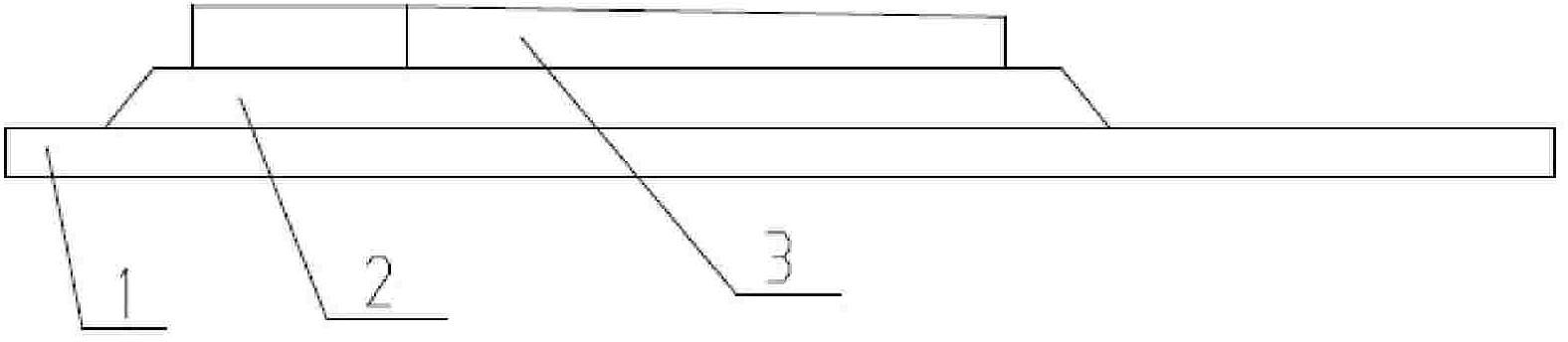

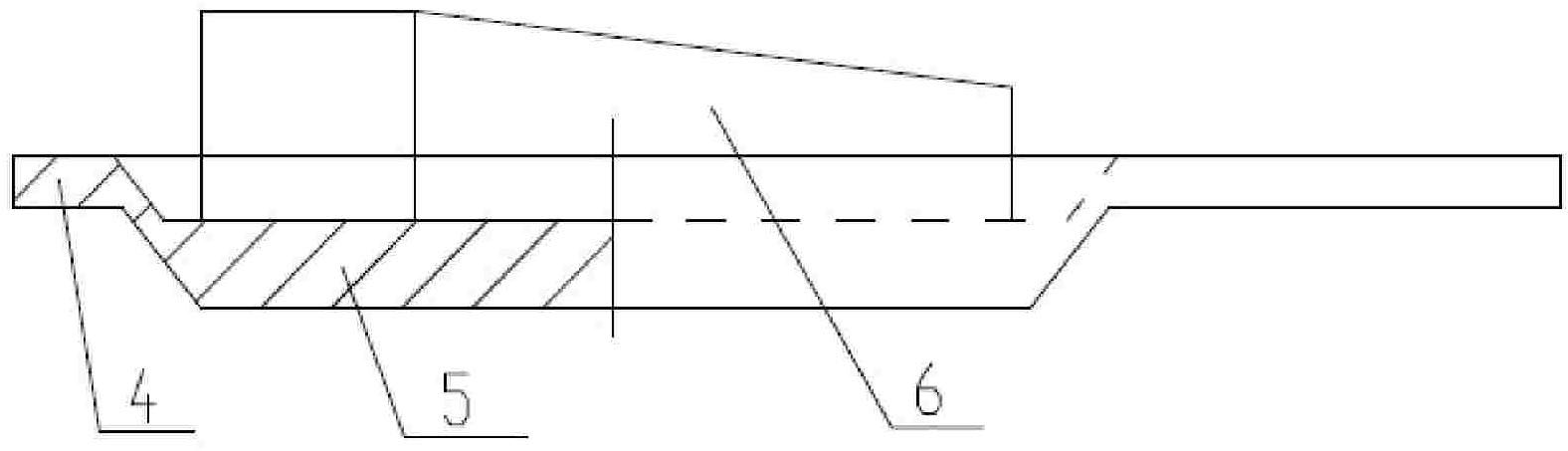

[0011] from figure 1 , figure 2 It can be seen from the figure that a casting pattern is horizontally divided into upper and lower two types at the largest cross-section of the casting, the lower pattern 4 is provided with a groove 5, and the groove 5 sinks into the parting surface by 50 mm, and the upper pattern 1 Correspondingly, a boss 2 is provided, and the boss 2 is 50 mm higher than the parting surface. This can ensure that the upper and lower models have enough sand to eat.

[0012] During manufacturing, the upper model 3 and the lower model 6 are split at the largest section of the cast casting, and processed according to the split diagram. Then the upper model 3 is installed and fixed on the upper model plate 1, as figure 1 Shown; The lower model 6 is installed and fixed on the lower model plate 4, as figure 2 shown.

[0013] When the casting is produced, the upper mold plate 1 and the lower mold plate 4 of the upper mold 3 and the lower mold 6 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com