Tube drawing machine

A pipe machine and shell technology, applied in the field of old pipes, can solve the problems of low efficiency, labor and time-consuming, difficult operation, etc., and achieve the effects of high efficiency, good effect and fast pipe extraction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

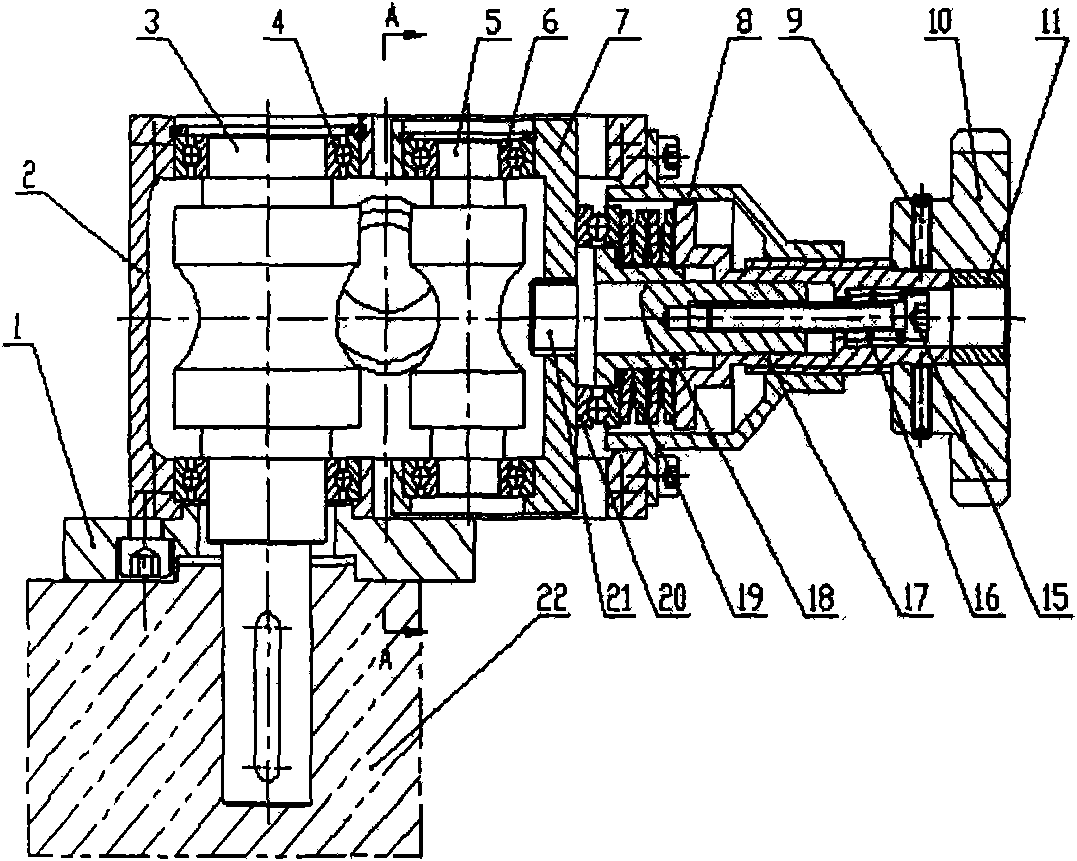

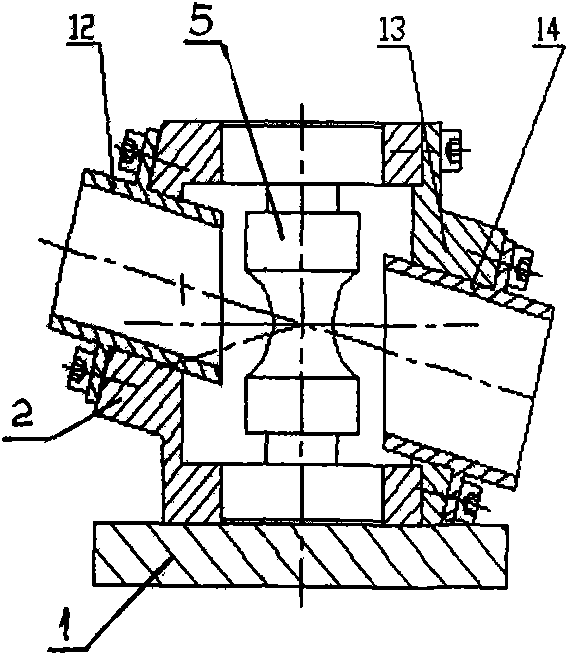

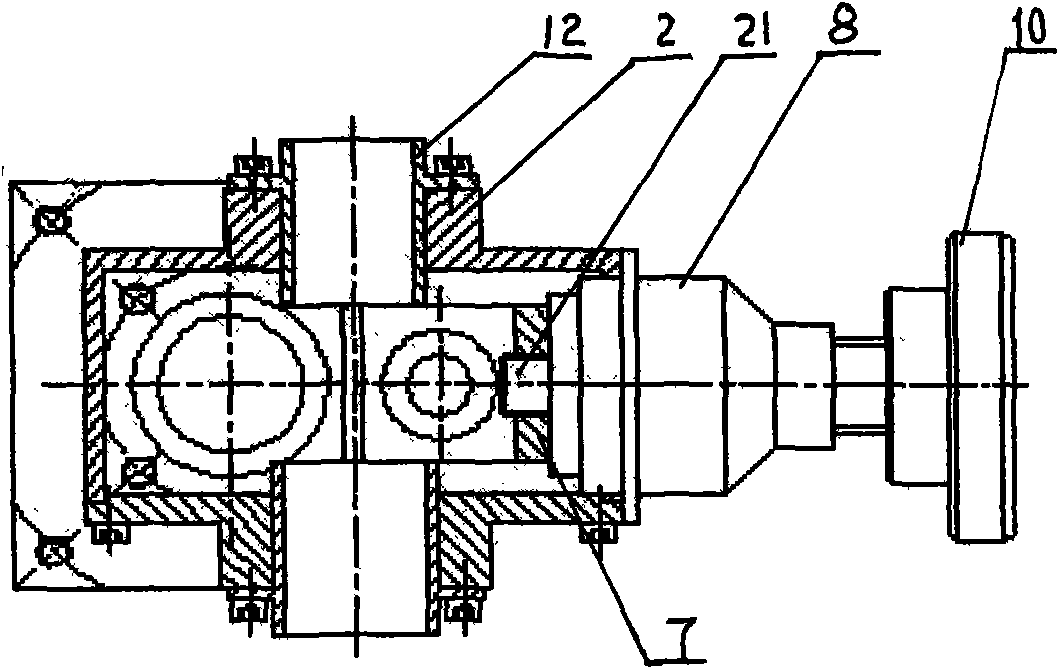

[0010] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0011] Depend on Figure 1-Figure 3 It can be seen that the lower end of the housing 2 of the present invention is connected to the motor 22 by bolts connecting the backing plate 1, the driving wheel 3 is radially installed in the housing 2 cavity, and the sliding frame 7 is arranged on the right side of the housing 2 cavity, and the radial direction is equipped with The driven wheel 5 and the right end of the sliding frame 7 are fixed with a base column 21, and the right side of the base column 21 shaft shoulder is sleeved with a transition sleeve 18, on which a thrust bearing 20, a butterfly spring 19, a guide sleeve 17, and a base column 21 are arranged in sequence. Screw 9 and hand wheel 10 are passed through the right side end, screw rod 15 is installed in the inner cavity of base column 21, spring 16 is set on its outer wall, inclined thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com